Experiment Name:

Lab Report: Determination of crimp% of woven fabric by using WIRA crimp tester.

Introduction:

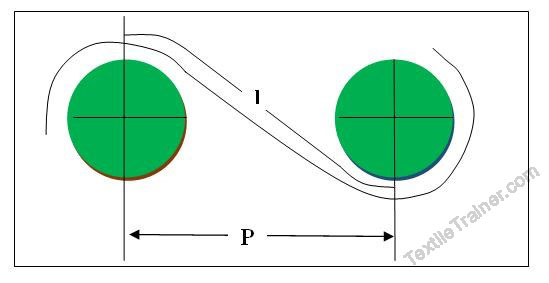

The value of measuring crimp is overlooked by many technicians. Crimp affects the finishing process as well as such fabric properties as abrasion, strength, and elongation. Even though a fabric has a square construction, that is, the same yarn size in warp and filling and the same number of ends and picks, it will not have balanced strength unless the crimp is the same in both the warp and filling yarns. The crimp percentage is the mean difference between the straightened thread length and the distance between its ends while in the cloth. It is expressed as a percentage. In order to define a crimp, two values are necessary: the length of the cloth from which the yarns are removed and the straightened length of the thread. In order to straighten the thread, tension must be applied, just sufficient to remove all the kinds without stretching the yarn. There is no way to remove all the crimps before the yarn itself begins to stretch in practice. .

The standardized tensions recommended in the B.S. Handbook are given below:

| Yarn | Count | Tension(cN) |

| Cotton | Finer than 7 tex | 0.75 ×tex |

| Coarser than 7 tex | (0.20× tex) + 4 | |

| Woolen & Worsted | 15 to 60 tex | (0.20× tex) + 4 |

| 60 to 300 tex | (0.07 ×tex) + 12 | |

| All man-made continuous filament yarns | All counts | Tex / 2 |

Objectives:

- To know about crimp percentage.

- To know crimp geometry

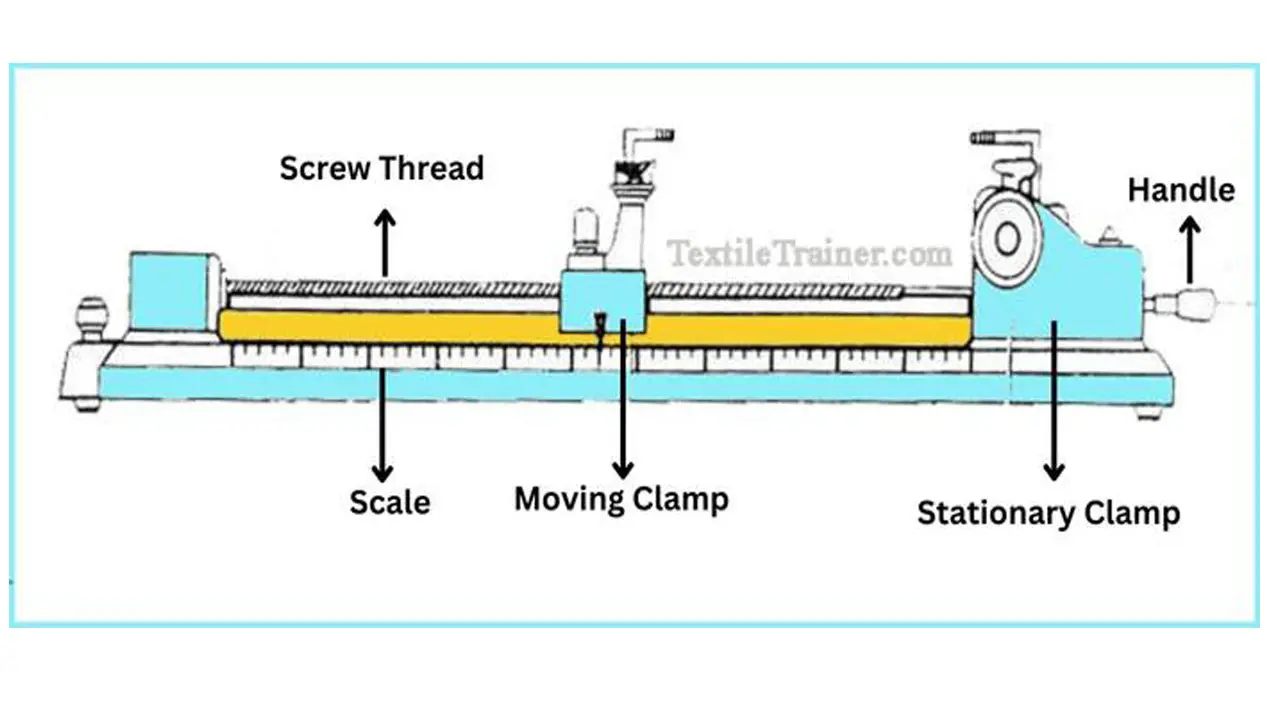

- Come to learn W.I.R.A crimp tester

- To know how to calculate crimp percentage.

Apparatus:

- W.I.R.A Crimp tester

- Fabric sample

- Scissor

- Scale

- Calculator

Standard testing temperature:

An atmosphere at the prevailing barometric pressure with a relative humidity of 65% and temperature of 200 C is called standard testing temperature.

Preparation of specimen:

At first we have to select the warp and weft way of fabric. Then we select test length of fabric. Here we will take 13*13 inch2 fabric. our crimp length of the yarn is 13 inch. where a higher degree of accuracy is necessary special crimp testers are used . Here we will take 10 threads, 5 for warp way and 5 for weft way. Here we will used The W.I.R.A crimp tester.

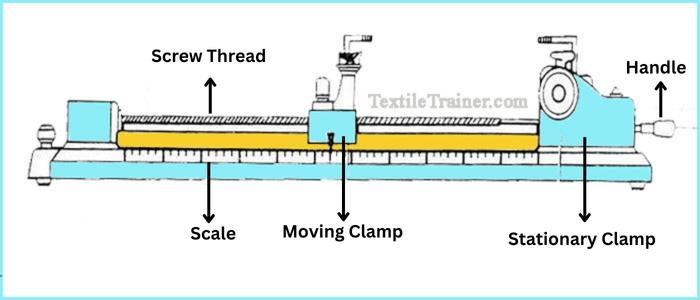

Diagram of Crimp Tester:

Working Procedure:

- Initially, a dissecting needle is used to separate the central part of the first thread from the flap fringe. However, the outer ends are left attached.

- By removing one end from the cloth and placing it in the tester’s grip, and leaving the other end in the second grip, we can transfer the thread from the cloth to the tester without losing the twist.

- After calculating the standard tension, set the tension in the machine.

- We will now see a gradual increase in tension.

- A scale is used to determine the length of the yarn after tension has been applied.

- From these two lengths, we can calculate the crimp percentage.

- This will enable at least 5 crimp percentages for warp and 5 crimp percentages for weft to be calculated, and the average crimp percentage will be found.

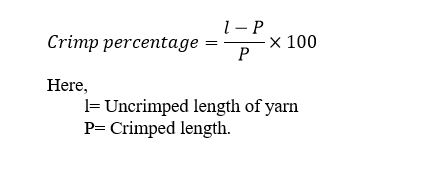

Calculation:

Here,

Count of the tested yarn both warp and weft= 30 Ne

For load calculation, we will convert English count to Tex count.

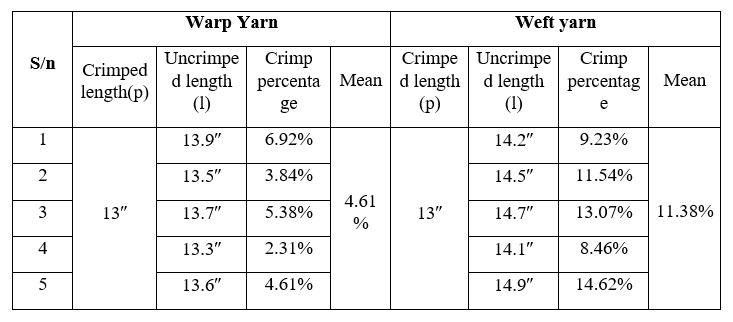

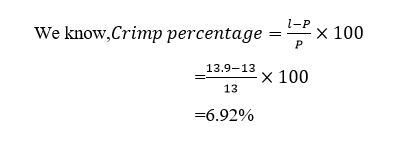

From Warp way, specimen 01

Crimped length of the yarn (p)=13 inch

Un-crimped length of the yarn (l)=13.9 inch

Rest specimen’s crimp percentage is calculated same way that mention above.

Then we calculated average crimp percentage for warp and weft way.

Average warp crimp percentage 4.61%

Average weft crimp percentage 11.38%

Conclusion:

From our calculation, we see, crimp percentage of warp yarn is low. Because, warp yarns are kept tension during weaving process. One the other hand, sizing process is done on warp yarn. As a result, strength of warp yarn is high than weft yarn. On the other hand, weft yarns are kept in low tension and use low quality. As result, weft yarn show more crime percentage.

References

- Booth, J. (2008). Principles of Textile Testing. New Delhi: CBS Publishers & Distributors.

- Corbman, B. P. (1983). Textiles Fiber to Fabric. New York: Mc Graw Hill.

- Hamby, E. B. (1993). Handbook of Textile Test and Quality Control. New York: Wiley Eastern Limited.

- HU, J. (2008). Fabric Testing. New York: Woodhead Publicatioing Limited.

I truly appreciate this blog.Really thank you!

Thanks for comments.

Great, thanks for sharing this post. Really Cool.

Thanks too….Please support us….

Enjoyed every bit of your post.Much thanks again. Fantastic.

thanks too….please support us….

Very informative blog post. Fantastic.

please support us.

I really like and appreciate your article.Really looking forward to read more. Much obliged.

thanks too……please support us….

Looking forward to reading more. Great article. Really Cool.

please share our article…

Hey, thanks for the blog.Really looking forward to read more. Fantastic.

Thanks for sharing, this is a fantastic article post.Really looking forward to read more. Great.

Thanks

Thanks again for the article.Really looking forward to read more. Really Great.

Thanks too..

A big thank you for your article post.Really thank you! Will read on…

This is one awesome blog article. Great.

Major thanks for the blog article.Much thanks again. Keep writing.

Appreciate you sharing, great blog post.Really thank you! Much obliged.

Major thankies for the blog article.Really looking forward to read more. Awesome.

Thanks so much for the article.Much thanks again. Cool.

keep visit our site.

wow, awesome blog post. Fantastic.

keep visit our site.

Very informative article.Thanks Again. Really Great.

I really like and appreciate your post.Really thank you! Great.

I am so grateful for your blog article.Really looking forward to read more. Great.

Looking forward to reading more. Great blog article.Really looking forward to read more. Really Great.

Thanks too

I appreciate you sharing this article.Much thanks again. Fantastic.

Very good blog.Really looking forward to read more. Fantastic.

Very informative blog.Really thank you! Really Cool.

I value the blog.Really thank you! Really Cool.

Really enjoyed this article.

Enjoyed every bit of your article.Thanks Again. Keep writing.

Im thankful for the blog. Will read on…

Awesome article post.Much thanks again. Fantastic.

Im grateful for the article.Thanks Again. Much obliged.

Thanks for sharing, this is a fantastic post.Really looking forward to read more. Really Cool.

Enjoyed every bit of your article. Cool.

Wow, great article.Thanks Again. Fantastic.

Very neat article.Much thanks again. Keep writing.

This is one awesome blog. Keep writing.

Great, thanks for sharing this blog article.Really looking forward to read more. Great.

Say, you got a nice blog post.Thanks Again. Much obliged.

Thanks so much for the blog article.Thanks Again. Really Cool.

I truly appreciate this blog article. Cool.

I really like and appreciate your blog article.Really thank you! Really Great.

Thanks so much for the blog. Much obliged.

wow, awesome blog post.Thanks Again. Want more.

Very good blog post. Want more.

I loved your blog post.Thanks Again. Want more.

Thanks so much for the blog post.Really thank you! Much obliged.

A round of applause for your blog article. Want more.

Thank you for your blog post.Really looking forward to read more. Fantastic.

I am so grateful for your article post.Really looking forward to read more. Really Cool.

I truly appreciate this blog article.Really looking forward to read more. Really Cool.

Thanks for sharing, this is a fantastic article post. Really Cool.

I loved your blog post.Really looking forward to read more. Much obliged.

I loved your blog article. Much obliged.

Thanks again for the blog post. Keep writing.

I appreciate you sharing this article post.Thanks Again. Really Great.

Thanks a lot for the blog article.Really looking forward to read more. Really Great.

I truly appreciate this blog.Much thanks again. Keep writing.

Very good blog article.Thanks Again. Fantastic.

I truly appreciate this post.Thanks Again.

Fantastic article.Really looking forward to read more. Fantastic.

Fantastic article post.Thanks Again. Great.

Thanks for sharing, this is a fantastic article post. Cool.

Thank you for your blog.Really thank you! Fantastic.

Fantastic blog post.Thanks Again. Keep writing.

Really informative blog article.Really thank you! Much obliged.

Im thankful for the post. Really Cool.

This is one awesome article post. Really Great.

Awesome blog article.Thanks Again.

Very neat article.Thanks Again. Really Great.

Thanks a lot for the blog post. Much obliged.

Welcome

Im thankful for the article.Really looking forward to read more.

Hey, thanks for the blog article.Much thanks again.

I really enjoy the blog post.Much thanks again.

I think this is a real great blog article. Fantastic.

I really liked your article post.Much thanks again. Much obliged.

I loved your article post.

This is one awesome article.Thanks Again. Much obliged.

I loved your article.Thanks Again. Keep writing.

Thanks so much for the blog article. Much obliged.

I value the blog. Awesome.

Really enjoyed this blog article.Really thank you! Awesome.

Awesome blog post.Much thanks again. Cool.

I really like and appreciate your post.Really thank you! Great.

Thanks a lot for the blog.Much thanks again. Keep writing.

Looking forward to reading more. Great blog post.Really thank you! Really Cool.

Really appreciate you sharing this post.Thanks Again. Great.

Hey, thanks for the blog.Really looking forward to read more. Cool.

Im thankful for the post. Fantastic.

Very good blog post. Fantastic.

Really appreciate you sharing this blog article.Really thank you! Cool.