What is Artificial Neural Network (ANN)?

The Artificial Neural Network (ANN) is an algorithm based on brain function used to model complicated patterns and forecast issues. An Artificial Neural Network (ANN) develops from the concept of Biological Neural Networks in the human brain. Artificial neural networks were developed as a means of replicating the functions of the human brain. Although they are not identical, ANNs are extremely similar to biological neural networks. The ANN algorithm only accepts numeric and structured data. Today automatic fabric inspection is done by ANN.

The inspection of fabric quality is one of the major problems that fabric manufacturers face in the textile industry today. Textile manufacturing is the process of converting various types of fibers into yarn, which is woven into fabric and then made into a variety of products. Weaving is the process of interlacing two distinct yarns called warps and wefts in order to create a fabric. If there is an abnormality in the fabric that prevents the user from accepting the fabric as a whole, then the fabric has a fabric fault. The fault detection process is currently performed manually after a sufficient amount of fabric has been produced in order to detect a fault. There is a great deal of repetition and dullness to the nature of the work. Manual inspection has a possibility of human error as well as having a high inspection time, and therefore it is uneconomical to do so. It has been proposed in this study that a computer based inspection system could be developed for identifying defects in woven fabrics using image processing and Artificial Neural Networks (ANN) with the benefit of a low cost and a high detection rate. There are four types of defects in this fabric. They are holes, stains, warp floats, and weft floats. In order to inspect the fabric, the inspection system acquires high-quality images of the fabric without causing any vibrations. It is then that the acquired images are first normalized and pre-processed using image processing techniques, and then the pre-processed image is converted into binary images based on the threshold value based on the preprocessed image. The binary image is extracted into its features and these features are given as input to the Artificial Neural Network (ANN), which uses the Back Propagation algorithm to calculate the weighted factors and generates the output from the binary image. A neural network is trained using 115 defect-free and defected images that are used to train the ANN.

Benefits of ANN:

The fabric quality control process is one of the most crucial processes in the garment and textile manufacturing workflow, as this essential precondition, the traditional manual fabric inspection methods always seem to take a very long time and are not always reliable. To improve the quality control process of the fabric, the ANN system automates the process of fabric quality control. The following are a few of the most important benefits that are mentioned below:

1. Improved Accuracy & Efficiency:

An artificial neural network (ANN) is a system that uses advanced algorithms and image recognition technology in order to detect defects and inconsistencies in fabrics. As a result, there is a higher level of accuracy in detecting defects, thereby reducing the possibility of human error in detecting them. An ANN system can significantly reduce the time it takes to inspect a fabric when it is used in conjunction with the system. The reason why this is so is that the system is able to inspect fabric at a much faster rate than a human would be able to do.

2. Cost Saving:

ANN can result in cost savings as a result of the reduction in the need for human inspectors, resulting in a freeing up of resources and a reduction in labor costs over time. Especially for companies that handle large volumes of fabric and require fast turnaround times, this can be particularly beneficial.

3. Decreased manpower, reduced risk of human error:

As part of the garment production process, fabric inspections take place several times throughout the process. The manual inspections are carried out under special lighting conditions by alert workers who are capable of slowly sifting through the fabric in search of defects. Fatigued workers are more likely to let defective garments pass inspection checks when they are fatigued, leading to rejects and product recalls as a result. An ANN system fabric inspection machine is capable of high accuracy inspections and does not require the use of additional lighting or equipment to perform the inspection. Using pre-programmed algorithms to predict fabric properties, the smart machines are able to quickly inspect products using their preprogrammed algorithms, enhancing the efficiency of the inspection process. The ANN system fabric inspection machines do not get tired like humans do, so they can easily check bulk production amounts as they won’t get tired like humans do. In order to increase factory production and reduce labor costs, excess manpower can be diverted to other areas of the factory.

4. Increased automation, higher profits:

In contrast to manual workers, AI fabric inspection machines can process large quantities of fabric per day. The program holds a database full of product images, enabling them to access and compare historical and real-time data. The entire production process is smoothed by speeding up quality control checks. Human error is reduced by automation, which reduces the amount of human involvement in production. By automating repetitive tasks, factories become more efficient and machines become smarter. The smoother the production process and the higher the quality of the product, the more orders factories can take on, resulting in increased profit for textile manufacturers.

5. Consistency:

By using ANN systems, fabric inspection quality can be maintained consistently at a high level. Because the system is not subject to the same level of risk as human inspectors, such as being fatigued or distracted, it is not subject to the same level of variability as human inspectors.

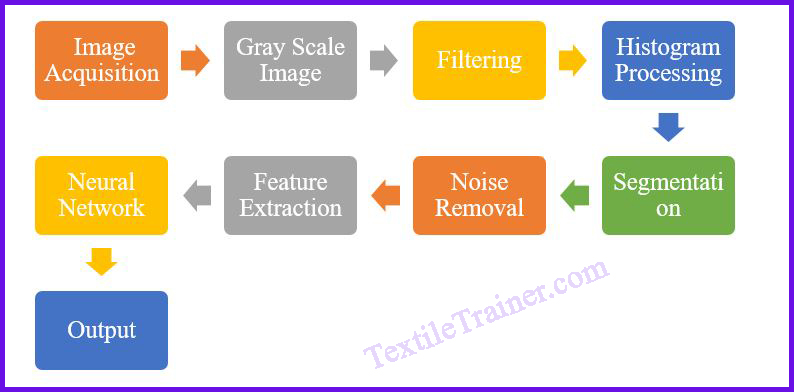

Working Principle of ANN:

1. Image Acquisition:

The first stage of any vision system is the image acquisition stage. Different types of camera can be used for this application such as CCD (Charged Coupled Device) camera, CMOS (Complementary Metal Oxide Semiconductor) camera, Digital camera, etc. The pixel value of these cameras is around 320 × 420 pixels. After the image has been obtained, various methods of processing can be applied to the image to perform different tasks. If the image has not been acquired satisfactorily then the intended tasks may not be achievable. The following are the various methods for image acquisition.

- Laser Ranging System

- Active and Passive Stereoscopic Methods

- Structured Light Methods

- Shape from Shading Methods

- Moire Fringe Methods

2. Gray Scale Image:

In order to get rid of the hue and saturation information from the acquired image while retaining the luminance information, it needs to be converted into gray scale.

3. Filtering & Histogram Processing:

This is done by the implementation of a kernel within a filter, which consists of a small array that is applied to each pixel within an image along with its neighbors. For most applications, the center of the kernel is aligned with the current pixel, and consists of a square with an odd number of elements in each dimension, with the current pixel as the center of the square. In order to apply a filter to an image, a process known as convolution is used. Convolution can be applied either spatially, or it can be applied in the frequency domain. Using the CONVOL function, you will be able to perform this convolution process for the entire image.

4. Segmentation:

There is a process of segmentation that involves partitioning an image into homogeneous groups of pixels based on some criterion that determines their homogeneity. There must be a homogeneity between adjacent groups, which means that different groups should not cross each other. This grouping of information is called a segment. As a matter of fact, most digital images are arranged on a rectangular grid. Due to the way in which image sensors are arranged on cameras and scanning equipment, this is mainly due to the arrangement of those sensors.

5. Noise Removal:

There are many types of noise in digital images. In the acquisition of an image, noise is caused by errors. Images can be contaminated with noise in several ways, depending on how they are created. Noise is caused by the film grain if the image has been scanned from a photograph made on film. Noise can also be caused by damaged film or by the scanner. When images are directly acquired digitally, noise can be introduced by the mechanism for collecting the data (for example, a CCD detector). It is possible for noise to be introduced into image data when it is transmitted electronically.

6. Feature Extraction:

Feature Extraction is a method of capturing visual content of images for indexing & retrieval.

- feature construction

- feature subset generation

- evaluation criterion definition

- evaluation criterion estimation

Textures can be rough or smooth, vertical or horizontal etc generally they capture patterns in the image data. Example repetitiveness and granularity • Texture features are – Statistical measures

- Entropy

- Homogeneity

- Contrast

7. Artificial Neural Network:

In areas such as pattern recognition and classification, artificial neural networks have shown promise as generalizations of mathematical models of human cognition. Neutral networks are composed of simple elements called neurons that process input data. Signals are carried between these neutrons by links. Weights are applied to each connection link so that the transmitted signal can be multiplied. The output signal is determined by applying an activation function to each neuron’s input. It is possible to present bias terms to solve specific problems with obvious result-tendencies. Using neural networks as a classifier requires two phases – training and testing. To produce the desired response, the neural network adjusts its weights during the training phase. When the actual output response matches the desired one, the training phase has been completed (i.e., the network has acquired knowledge). As part of the testing phase, the neural network is asked to classify a new set of images and its performance is evaluated. The neural networks were trained by the “back propagation” algorithm to detect and classify woven fabric defects. Input vectors for the neural network were the feature vectors.

Conclusion:

In the fabric inspection process, the ANN inspection system offers unprecedented accuracy, efficiency, and cost-effectiveness. Using advanced technologies like AI, machine learning, and computer vision, this system can detect defects and anomalies at an incredibly fast and precise rate. Through this experiment, we learned how to work an automatic inspection system by using an artificial neural network (ANN). I would like to thank our teacher for taking the time to help us out.

References

- 2, P. B. (2012). Fabric Inspection System using Artificial Neural Networks. International Journal of Computer Engineering Science, 20-27.

- 2, P. B. (2014). An intelligent system for automatic fabric inspection. Research gate, 308-312.

Thanks so much for the article post.Thanks Again. Keep writing.

ok.

Major thankies for the blog post.Much thanks again. Great.

please support us….

I really liked your blog.Really thank you! Really Great.

keep visit our site…..

I think this is a real great blog.Really thank you! Want more.

keep visit our site…

I think this is a real great post.Really looking forward to read more. Much obliged.

thanks…

Really informative post.Really thank you! Will read on…

keep visit our site…..thanks too…

Thanks for the blog post.Really thank you! Great.

thanks too. please support us.

Thanks for the blog article.Much thanks again. Want more.

ok, we will try.

I truly appreciate this blog article.Really looking forward to read more. Fantastic.

please support us…

Great article post.Much thanks again. Much obliged.

please support us.

Thanks-a-mundo for the post.Really thank you! Cool.

It’s an amazing paragraph for all the online visitors; theywill obtain benefit from it I am sure.

Thanks a lot

A big thank you for your article post.Really looking forward to read more. Want more.

A round of applause for your post.Much thanks again. Really Great.

Im obliged for the article.Much thanks again. Keep writing.

keep visit our site.

Thanks so much for the blog post.Really looking forward to read more. Keep writing.

keep visit our site….

Very good blog.Really thank you! Awesome.

Looking forward to reading more. Great blog.Really thank you! Much obliged.

Thanks for sharing, this is a fantastic post.Thanks Again. Cool.

keep visit our site.

Thanks again for the blog post.Really looking forward to read more. Keep writing.

keep visit our site.

Thank you ever so for you blog post.Really looking forward to read more. Awesome.

I loved your blog post.Much thanks again. Really Great.

Really enjoyed this blog post.Really looking forward to read more. Really Cool.

Thanks again for the post.Thanks Again. Much obliged.

I really like and appreciate your blog post.Really thank you! Really Cool.

Really enjoyed this blog.Really looking forward to read more.

Very good blog article.Really thank you! Want more.

wow, awesome blog.Thanks Again. Awesome.

Very neat blog post.Much thanks again. Really Cool.

A big thank you for your article post.Really thank you! Want more.

Thank you for your article.Thanks Again. Will read on…

Thanks again for the blog article.Much thanks again. Cool.

Im obliged for the post.Much thanks again. Keep writing.

I think this is a real great article post.Really thank you! Much obliged.

Very informative blog post.Thanks Again. Want more.

I appreciate you sharing this article post.Thanks Again. Much obliged.

Thanks a lot for the blog.Much thanks again. Really Great.

A big thank you for your blog article.Really thank you! Much obliged.

Looking forward to reading more. Great blog.Much thanks again. Cool.

A round of applause for your blog article.Really thank you!

Say, you got a nice blog article.Really thank you! Keep writing.

Say, you got a nice article post.Much thanks again. Keep writing.

I truly appreciate this post.Really thank you!

Thanks for sharing, this is a fantastic blog article.Thanks Again. Much obliged.

Thanks again for the blog post. Want more.

Very good article post.Really thank you! Awesome.

This is one awesome article post.Thanks Again. Fantastic.

Enjoyed every bit of your blog.Really thank you! Really Great.

I truly appreciate this blog post.Thanks Again. Awesome.Loading…

Say, you got a nice post.Much thanks again. Great.

A big thank you for your blog post.Thanks Again. Really Great.

Appreciate you sharing, great article post.Really thank you! Really Cool.

Really enjoyed this article.Really looking forward to read more.

I cannot thank you enough for the article.Really thank you! Will read on…

I really liked your blog post. Really Great.

Thanks for the article post. Much obliged.

I really like and appreciate your post.Much thanks again. Much obliged.

I really enjoy the blog post.Much thanks again.

Thanks so much for the blog article.Really thank you! Fantastic.

I appreciate you sharing this blog article.Really thank you! Will read on…

Really informative article.Really looking forward to read more. Great.

I am so grateful for your article post.Really thank you! Really Great.

A big thank you for your blog.Much thanks again. Fantastic.

Thanks for the blog.Much thanks again. Much obliged.

Good article. I’m experiencing many of these issues as well..

Im grateful for the blog article.Really looking forward to read more. Will read on…

Fantastic blog.Really looking forward to read more. Keep writing.

Appreciate you sharing, great blog post. Really Great.

Awesome article post.Really thank you! Really Great.

Very neat blog post.Thanks Again. Much obliged.

Im grateful for the article post.Thanks Again. Much obliged.

Wow, great article post.Much thanks again. Much obliged.

Major thanks for the post.Much thanks again. Really Cool.

Great blog.Thanks Again. Will read on…

Very neat article.Really looking forward to read more. Really Cool.

Thank you ever so for you blog post. Really Cool.

Enjoyed every bit of your post.Really looking forward to read more. Keep writing.

Appreciate you sharing, great article. Keep writing.

I loved your blog article.Really looking forward to read more.

Really appreciate you sharing this post.Thanks Again. Much obliged.

Appreciate you sharing, great blog.Thanks Again. Want more.

Very informative blog.Really looking forward to read more. Keep writing.

Very informative post.Much thanks again. Really Cool.

Hey, thanks for the article. Fantastic.

Thank you for your article. Fantastic.

Really informative blog post. Cool.

I am so grateful for your article post.Much thanks again. Much obliged.

I really liked your blog article. Awesome.

Im grateful for the post.Really looking forward to read more. Will read on…

Hello! I could have sworn I’ve been to this blog before but after checking through some of the post I realized it’s new to me. Anyways, I’m definitely delighted I found it and I’ll be book-marking and checking back frequently!

Thanks

I really enjoy the blog post.Really thank you! Great.

Great article post.Thanks Again. Great.

Really informative post.Thanks Again. Want more.

Im grateful for the blog article. Will read on…

Im thankful for the post.Thanks Again. Fantastic.

I really liked your post.Really looking forward to read more. Awesome.

I cannot thank you enough for the article post.Really thank you! Much obliged.

Really informative post. Awesome.

I truly appreciate this article post.Thanks Again. Cool.

Hey, thanks for the post.Thanks Again. Great.

Very informative post.Thanks Again. Cool.

Im grateful for the article post.Really thank you! Really Great.

Really informative post.Really looking forward to read more. Want more.

This is one awesome article post.Much thanks again. Awesome.

I am so grateful for your blog. Cool.

I loved your blog.Really looking forward to read more. Awesome.

Appreciate you sharing, great blog. Will read on…

Awesome blog post. Will read on…

I value the article.Really looking forward to read more. Much obliged.

I appreciate you sharing this article.Really looking forward to read more. Want more.

This is one awesome blog post.Really thank you! Much obliged.

I really like and appreciate your blog article.Thanks Again.