Introduction:

Some factors affects textile testing result directly. It is important to know factors affecting test results. Textile testing is a crucial aspect of the textile industry, as it is used to evaluate the quality, safety, and performance of textile materials and finished products. Textile testing involves a range of tests and analyses to assess various properties of the materials, such as strength, durability, colorfastness, and resistance to various environmental factors. The results of textile testing are used by manufacturers to ensure that their products meet established standards for quality, safety, and performance, and to make improvements to their production processes. Additionally, textile testing is often required by law or regulations to ensure compliance with established standards. In this context, it is important to understand the factors that can affect the results of textile testing, the uses of the results, and the importance of textile testing for various industries and consumers.

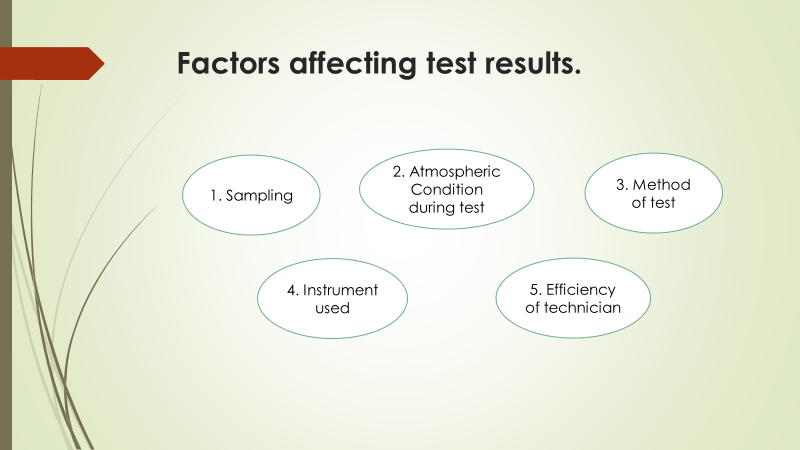

Factors affecting test results:

- Sampling/Sample Preparation: The preparation of textile samples before testing is critical to obtaining accurate results. The sample should be representative of the lot being tested, and any anomalies should be noted and addressed before testing.

- Environmental conditions/Atmospheric Condition: The temperature and humidity in the testing environment can affect the behavior and properties of textile materials. Testing should be conducted in a controlled environment to minimize the impact of these factors. The temperature should be controlled to within a specified range, typically between 20°C to 25°C (68°F to 77°F). Some tests may require a higher or lower temperature range, so it is important to refer to the specific test standard or method for guidance. The humidity level should be controlled to within a specified range, typically between 45% to 65%. Some tests may require a higher or lower humidity range, so it is important to refer to the specific test standard or method for guidance. One common condition that fabrics may be tested at is 22° C / 65% RH to meet ASTM & ISO test specs.

- Testing methodology/Method of test: The testing method used can also impact the results obtained. Different methods may have varying levels of sensitivity and specificity, and some methods may be more appropriate for certain types of textiles than others.

- Testing equipment/Instrument used: The accuracy and precision of the testing equipment used can impact the results obtained. Equipment calibration and maintenance should be performed regularly to ensure accurate and reliable results.

- Operator skill and technique/Efficiency of technician: The skill and technique of the operator conducting the test can impact the results obtained. Proper training and adherence to testing protocols can minimize operator error.

Some other factors that are affecting the tested results are discussed below:

1. Variability in the textile material: Textile materials can have inherent variability due to differences in manufacturing processes, fiber content, and other factors. Testing should be conducted on multiple samples to account for this variability.

2. Interference from external factors: Other external factors such as contamination or the presence of other materials can interfere with textile testing results. Careful attention should be paid to sample handling and testing protocols to minimize these effects.

3. Data analysis: The accuracy and reliability of the results depend on the accuracy of data analysis techniques. Proper statistical analysis and interpretation of results are critical to obtaining accurate conclusions from textile testing data.

4. Fabric structure: The structure of the textile material, such as its weave or knit pattern, can affect the behavior and properties of the material. Different testing methods may be needed for different types of structures.

5. Age and condition of the textile: The age and condition of the textile can also impact the results obtained from testing. Textiles that have been in storage or in use for a long time may have undergone changes in their properties that can affect test results.

6. Chemical treatments: The use of chemical treatments on textiles, such as finishes or coatings, can also affect testing results. The effects of these treatments should be considered when selecting testing methods and interpreting results.

Conclusion:

Overall, obtaining accurate and reliable results from textile testing requires careful attention to sample preparation, testing methodology, environmental conditions, and data analysis. Understanding the factors that can impact test results can help to ensure that testing is conducted in a consistent and reliable manner.

Great blog you’ve got here.. It’s difficult to find excellent writinglike yours nowadays. I really appreciate individuals like you!Take care!!

ok. thanks for comment.

I think this is a real great blog. Awesome.

please support us.

I really enjoy the blog post.Really thank you! Awesome.

thanks too…..please support us.

Enjoyed every bit of your article.Much thanks again. Want more.

ok, I will try.

Really appreciate you sharing this article.Really thank you! Will read on…

thanks too……please support us….

Say, you got a nice article. Will read on…

please support us….

Thanks for sharing, this is a fantastic blog post.Much thanks again. Really Great.

keep visit our site…..

I really liked your article.Much thanks again. Keep writing.

keep visiting.

Thank you for your blog article.Really thank you! Awesome.

Thank you dear. Stay with us. Happy reading.

Pretty! This was a really wonderful article.Thank you for supplying these details.

keep visit our site…

I really like and appreciate your blog. Much obliged.

Thanks for the blog.Really looking forward to read more. Cool.

Fantastic blog article.Really thank you! Want more.

I think this is a real great blog post.Much thanks again. Really Cool.

Thanks

Itís hard to find knowledgeable people in this particular subject, however, you sound like you know what youíre talking about! Thanks

Welcome for your nice complement.

Appreciate you sharing, great blog article.Thanks Again.

I appreciate you sharing this article.Really looking forward to read more. Awesome.

please support us….

Really enjoyed this blog article.Much thanks again. Keep writing.

keep visit our site….

Thank you for your blog. Awesome.

thanks too….please support us…

Thanks so much for the article.Thanks Again. Keep writing.

I appreciate you sharing this article post.Much thanks again. Great.

Really informative post.Really looking forward to read more. Fantastic.

What’s up colleagues, how is everything, and what you would like to say concerning this post, in my view its genuinely remarkable for me.

Really enjoyed this post.Thanks Again. Really Great.

This is one awesome blog.Really thank you! Keep writing.

Wow, great article post.Really thank you! Keep writing.

I think this is a real great blog.Really looking forward to read more. Will read on…

Thank you for your blog post.Really looking forward to read more. Will read on…

A big thank you for your article.Really thank you! Cool.

Fantastic blog.Much thanks again. Great.

Enjoyed every bit of your blog.Much thanks again. Fantastic.

Thank you ever so for you blog post.Really thank you!

Looking forward to reading more. Great article post.Really thank you! Really Great.

Thanks too……

I loved your blog post. Really Great.

keep visit our site.

Very informative article post.Really thank you! Great.

keep visit our site.

Thanks for the article.Thanks Again. Awesome.

Great post.Thanks Again. Really Cool.

wow, awesome post.Really looking forward to read more.

I value the blog post.Really thank you! Want more.

A big thank you for your blog article.Really thank you! Really Cool.

Enjoyed every bit of your post.Thanks Again. Awesome.

Thanks-a-mundo for the blog post. Fantastic.

Thanks

Say, you got a nice blog post.Thanks Again. Want more.

Welcome

I am so grateful for your blog.Thanks Again. Really Great.

Thank u so much

I cannot thank you enough for the blog article.Thanks Again. Much obliged.

wow, awesome blog. Awesome.

Wow, great blog article.Much thanks again. Really Great.

I think this is a real great article.Thanks Again. Great.

Fantastic blog.Thanks Again. Cool.

Thanks so much for the article. Want more.

Thanks a lot for the post. Cool.

Fantastic article post. Will read on…

I loved your article post. Much obliged.

Looking forward to reading more. Great article.Really looking forward to read more. Cool.

Thank you ever so for you article.Thanks Again. Much obliged.

I really liked your article.Really thank you! Keep writing.

Really informative blog.Thanks Again. Much obliged.

I loved your blog article.Really thank you! Great.

Awesome article post.Really looking forward to read more. Keep writing.

A round of applause for your blog. Cool.

Thank you for your article.Much thanks again. Really Great.

I really liked your blog.Much thanks again. Want more.

Awesome blog post. Great.

I value the article.Thanks Again. Cool.

Im thankful for the blog post.Thanks Again. Cool.

Thanks again for the blog post. Cool.

A big thank you for your blog article. Fantastic.

A big thank you for your blog.Much thanks again. Much obliged.

Enjoyed every bit of your post. Want more.

Awesome blog.Much thanks again. Really Cool.

Very neat post.Really thank you! Much obliged.

Very good post.Much thanks again. Fantastic.

Looking forward to reading more. Great blog article.Really thank you! Want more.

Really enjoyed this article.Much thanks again. Much obliged.

Really informative article.Really thank you! Really Cool.

A big thank you for your blog post. Great.

At this time I am going to do my breakfast, once having my breakfast coming again to readmore news.

Thanks a lot for the blog article.Much thanks again. Much obliged.

Welcome

Looking forward to reading more. Great blog article. Fantastic.

Thanks

Thanks a lot for the article post.Much thanks again. Cool.

Im grateful for the post.Really thank you! Really Cool.

This is one awesome article. Want more.

Thanks again for the blog article.Really looking forward to read more. Really Great.

Thank you ever so for you blog.Really looking forward to read more. Awesome.

Thanks for the blog post.Thanks Again. Really Great.

I appreciate you sharing this article.Really thank you!

I value the article.Really thank you! Keep writing.

Im thankful for the blog. Will read on…

I really like and appreciate your blog.Thanks Again. Want more.

I think this is a real great blog post. Fantastic.

Thank you for your blog post.Really looking forward to read more.

Enjoyed every bit of your article post.Really thank you! Want more.

Thank you for your blog article. Fantastic.

Thank you ever so for you blog article. Great.

I really like and appreciate your blog article.Really looking forward to read more. Want more.

Major thanks for the blog.Really looking forward to read more. Much obliged.

wow, awesome article.Really looking forward to read more.Loading…

Thank you ever so for you blog post.Thanks Again. Really Cool.

Really informative blog post.Much thanks again. Awesome.

Really informative article.Really thank you! Great.

Thanks a lot for the article.Really looking forward to read more. Keep writing.

Really informative blog article.Really thank you! Cool.

Awesome article post.Really looking forward to read more. Really Great.

Thank you ever so for you blog post.Really thank you! Really Cool.

Thanks for the article.Really looking forward to read more. Great.

I loved your blog.Really looking forward to read more. Fantastic.

Thanks for sharing, this is a fantastic post.Thanks Again. Really Great.

Fantastic post.Thanks Again. Cool.

Im grateful for the blog article. Will read on…

Thanks for sharing, this is a fantastic blog post.Much thanks again.

Thank you ever so for you blog post.Thanks Again. Awesome.

Thanks again for the article post.Really looking forward to read more. Cool.

Thank you for your post.Really looking forward to read more. Really Cool.

Awesome blog post.Thanks Again. Fantastic.

A round of applause for your blog article.Thanks Again. Great.

I really like and appreciate your article.Really looking forward to read more. Awesome.

Really informative article.Much thanks again. Keep writing.

I truly appreciate this blog.Really thank you! Fantastic.

Appreciate you sharing, great article post.Thanks Again. Awesome.

Hey, thanks for the post.Much thanks again. Really Cool.

Great, thanks for sharing this blog.Really thank you! Keep writing.

I loved your blog.Much thanks again. Fantastic.

Thanks again for the blog article. Keep writing.

Really appreciate you sharing this post.Really thank you!

Thank you ever so for you article post. Fantastic.

I really liked your article post.Much thanks again. Fantastic.

Thanks for sharing, this is a fantastic article post.Thanks Again. Great.

This is one awesome blog post. Keep writing.

Wow, great post.Thanks Again. Really Great.

Thanks for the post.Thanks Again.

Wow, great article post.Much thanks again. Much obliged.

I think this is a real great blog post.Really looking forward to read more. Much obliged.

I really enjoy the blog article.Much thanks again. Keep writing.

Awesome blog.Much thanks again. Really Great.

Really appreciate you sharing this blog.

I really enjoy the article post. Will read on…

Enjoyed every bit of your blog article.

Looking forward to reading more. Great blog.Much thanks again. Will read on…

Thanks again for the post.Much thanks again. Cool.

I truly appreciate this article post.Really looking forward to read more. Great.

Very informative blog article.Thanks Again. Awesome.

Im grateful for the post.Thanks Again. Really Cool.

Enjoyed every bit of your post.Thanks Again. Will read on…

Major thanks for the article.Really thank you! Awesome.

Enjoyed every bit of your post.Much thanks again. Cool.

Thanks for sharing such a fastidious opinion, piece of writing is fastidious, thats why i have read it entirely

I think this is a real great post.Thanks Again. Great.

I think this is a real great post.Really thank you! Much obliged.

Thank

I value the blog article.Really thank you! Really Great.

Thanks again for the article. Really Cool.

Thanks-a-mundo for the article post.Really thank you!

Welcome

I really liked your article.Much thanks again. Awesome.

I loved your article.Really thank you! Want more.

This is one awesome blog article.Thanks Again. Want more.

Thank you ever so for you article post. Will read on…

Thanks too

Very informative post.Really thank you! Keep writing.

Thanks

Appreciate you sharing, great post. Awesome.

That is a very good tip particularly to those fresh to the blogosphere. Brief but very precise info… Many thanks for sharing this one. A must read post!

Hey, thanks for the blog. Really Great.

Enjoyed every bit of your blog article.Really looking forward to read more. Want more.

I really enjoy the blog.Thanks Again.

Thanks-a-mundo for the article.Much thanks again. Will read on…

I am so grateful for your article.Much thanks again. Great.

Very neat blog article. Fantastic.

Very neat article post.

I loved your blog post.Really thank you! Want more.

A big thank you for your post.Much thanks again. Cool.

Thanks a lot for the blog article.Really thank you! Keep writing.

Say, you got a nice blog.Really thank you! Cool.

Thanks a lot for the article post.

Kerassentials are natural skin care products with ingredients such as vitamins and plants that help support good health and prevent the appearance of aging skin. They’re also 100% natural and safe to use. The manufacturer states that the product has no negative side effects and is safe to take on a daily basis.

Awesome blog.Really looking forward to read more. Much obliged.

Thanks again for the article.Thanks Again. Cool.

Kerassentials are natural skin care products with ingredients such as vitamins and plants that help support good health and prevent the appearance of aging skin. They’re also 100% natural and safe to use. The manufacturer states that the product has no negative side effects and is safe to take on a daily basis. Kerassentials is a convenient, easy-to-use formula. https://kerassentialsbuynow.us/

Fantastic article. Awesome.

Very informative article post.Really thank you! Cool.

Very neat article.Really looking forward to read more. Really Cool.