Introduction:

OD automatic batch mixer machine is described in easy way in this article. Jute batching is a simple process, usually containing only the emulsifying agent, mineral oil, and water as the only ingredients. In a basic sense, an emulsion is the intimate mixture of two immiscible liquids, where one is dispersed in droplets from inside the other. In other words, it is composed of two phases: the external phase and the internal phase. There is an external phase of water and an internal phase of mineral oil. A batching oil is usually a golden, amber-colored liquid, and water is a colorless liquid, but when the two are mixed together as an emulsion, the resulting liquid is an unsightly, milky white liquid with a golden sheen.

Objectives:

- To know what is emulsion.

- To know standard recipe of emulsion.

- Working principle of OD automatic emulsion mixer machine.

Standard recipe of emulsion:

| Water | 79.5% |

| Mineral Oil | 20% |

| Emulsifier | 0.5% |

| Total=100% | |

Function of elements:

Water:

- Softens the fiber.

- Increases fibre extensibility.

- Prevent excessive fiber breakage at the cards.

- Makes the fiber to easily bend round the pins and rollers.

- Reduces wt. loss.

- Gives required dampness and flexibility.

Oil:

- Increase fiber cohesion.

- Helps in proper drafting.

- Reduces quick evaporation of water from the fibre body.

- Lubricates the fibre and helps their free movement during processing.

Emulsifier:

- Reduces surface tension.

- Stabilizes the emulsion.

OD Automatic Batch Mixer Machine:

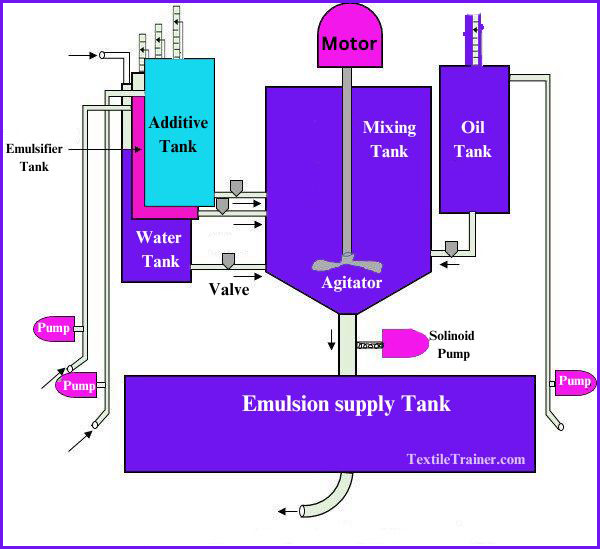

A first emulsifier and equal quantities of mineral oil are placed on the bottom of the mixing tank. Afterward, the remaining oil is added slowly and steadily, heated, and mixed for 35 minutes at a low temperature. A small amount of water and the additive of choice is then added, and the mixture is mixed for approximately 20 minutes until the desired form is achieved. The emulsification process begins when all the ingredients are added to the paddle, and the agitator on the paddle blows at high speed to agitate the mixture when the emulsification process is complete, the mixture is pumped into the supply tank. A further 20 minutes are to be spent in the reserve tank after the emulsion has been transferred from the mixing tank to the reserve tank. After that, it is taken to a softener or spreader machine, where it is put into action.

Faults of Emulsion:

Creaming:

When preparing an emulsion, it is not possible to make all the drops exactly the same size. The larger droplets move toward the surface of the water because they have a lower density than the water. As a result of these droplets, water is unevenly distributed and forms a layer on the surface, causing uneven distribution of emulsion as well. A defect such as this is known as creaming. As a result of this defect, yarn breaks more easily during the spinning process.

Causes of creaming:

- Bad agitation of the mixture.

- Improper oil selection.

- Not accurate mixing ratio of oil, water and emulsifier.

Remedy to avoid creaming:

- Using oil of high specific gravity.

- Emulsion should not be stored for long time.

- Using slow running paddles to stir the mixture, thus the droplet size can be kept small.

Breaking of Emulsion:

It is sometimes the case that the mixture is not uniform and so there are some places where it is dense and others where it is light. This defect is known as breaking, and it is a structural defect. As a result of faulty stirring equipment, this problem occurs. To avoid this problem, it is recommended that high speed agitation is use

Conclusion:

Jute is a fiber that is composed of lignin, so it is hard and brittle due to its composition. When subjected to abrasion and mechanical treatment, this material is easily broken down. To make it soft and easy, a mixture of some lubricating agent is used in order to make it soft and easy. In this experiment, we learned the concept of emulsion and how to prepare an emulsion as a result of our experiments. We would like to thank our teacher for helping us out. In the future, this experiment will be of great help to us in our careers.

I loved your blog.Thanks Again. Much obliged.

Thanks so much for the post.Really looking forward to read more. Much obliged.

keep visit our site..

Thanks for sharing, this is a fantastic blog article.Really looking forward to read more.

please support us….

Thank you ever so for you post. Awesome.

Keep visit our site…..

Im obliged for the blog.Really thank you! Fantastic.

please support us….

Really enjoyed this blog.Thanks Again. Want more.

ok, I will try…

I truly appreciate this article.Really looking forward to read more. Keep writing.

keep visit our site….

I am so grateful for your article post.Really looking forward to read more. Will read on…

thnx

F*ckin’ tremendous things here. I’m very glad to peer your post. Thank you so much and i’m taking a look ahead to touch you. Will you please drop me a mail?

Appreciate you sharing, great article post.Really thank you! Keep writing.

I am not absolutely sure where you’re receiving your info, but excellent subject. I wants to invest a while Mastering far more or comprehension extra. Many thanks for exceptional info I was looking for this info for my mission

Thanks a lot

Hello mates, pleasant article and fastidious arguments commented here, I am really enjoying by these.

please support us.

fantastic issues altogether, you just gained a emblem new reader. What might you recommend in regards to your put up that you simply made some days in the past? Any positive?

Thanks

I do not even understand how I stopped up right here, but I believed this post used to be good. I don’t recognize who you are but definitely you are going to a famous blogger should you are not already 😉 Cheers!

Thanks for the good writeup. It if truth be toldused to be a entertainment account it. Glanceadvanced to far brought agreeable from you! By the way, how can we keepin touch?

Great post. I was checking constantly this blog and I am impressed! Extremely helpful info specially the last part 🙂 I care for such info a lot. I was seeking this certain info for a long time. Thank you and best of luck.

Thank you

Thank you for your blog.Really thank you! Much obliged.

Looking forward to reading more. Great blog post. Really Great.

Enjoyed every bit of your blog article.Really thank you! Cool.

Greetings! Very useful advice within this post! It’s the little changes that produce the most significant changes. Thanks for sharing!

Thank you for your post. Much obliged.

I really enjoy the blog.Thanks Again. Keep writing.

Wow, great article.Really looking forward to read more. Awesome.

Enjoyed every bit of your blog. Want more.

ok, we will try…

I loved your blog.Really thank you! Cool.

thanks too….please support us……

I really like and appreciate your article post.Much thanks again. Really Great.

Enjoyed every bit of your blog.Really looking forward to read more. Will read on…

Thanks a lot for the article post.Thanks Again. Awesome.

help with college paper writing help with a paper

Great article. I am dealing with many of these issuesas well..

Enjoyed every bit of your post.Thanks Again. Fantastic.

keep visit our site.

Im obliged for the blog article.Thanks Again. Great.

hanks too……

Im thankful for the article post.Much thanks again. Will read on…

This is one awesome blog.Much thanks again. Really Great.

Thank you for your post.Thanks Again. Cool.

A big thank you for your blog.Much thanks again. Want more.

Enjoyed every bit of your article post.Thanks Again. Really Great.

This is one awesome blog article.Thanks Again. Fantastic.

I loved your article.Really looking forward to read more. Really Cool.

I really like and appreciate your blog article. Cool.

I am so grateful for your article.Thanks Again. Much obliged.

Thanks for sharing, this is a fantastic blog article.Thanks Again. Much obliged.

Thanks for sharing, this is a fantastic blog article.Really thank you! Cool.

Major thankies for the article.Much thanks again. Fantastic.

Great, thanks for sharing this blog.Much thanks again. Awesome.

I loved your article. Cool.

Say, you got a nice article post.Really looking forward to read more.

Very neat blog article.Much thanks again. Cool.

I really liked your blog.Thanks Again. Want more.

There are many blogs that already do this, and many of them are not successful.

I think this is a real great article post. Great.

Very informative article.Thanks Again. Awesome.

Im grateful for the blog article. Will read on…

Im grateful for the blog. Really Great.

Enjoyed every bit of your blog.Really thank you! Much obliged.

Awesome article post.Really thank you! Fantastic.

I truly appreciate this article post.Really thank you! Fantastic.

Im grateful for the post.Thanks Again. Much obliged.

I truly appreciate this blog article.Really looking forward to read more. Will read on…

Thank you for your post.Really looking forward to read more. Want more.

I think this is a real great blog article. Much obliged.

Appreciate you sharing, great article. Much obliged.

Major thanks for the post. Really Cool.

I appreciate you sharing this blog article.Really thank you! Great.

Thanks so much for the post.Really looking forward to read more. Want more.

Im thankful for the blog article.Really thank you! Awesome.

Thanks for sharing, this is a fantastic blog article.Really looking forward to read more. Awesome.

Enjoyed every bit of your blog.Really thank you! Keep writing.

Thank you for your article. Cool.

wow, awesome post. Keep writing.

Thanks again for the article.Much thanks again. Awesome.

I am so grateful for your article post.Really looking forward to read more. Great.

Hey, thanks for the blog article. Really Cool.

Very neat post.Really looking forward to read more. Really Cool.

Looking forward to reading more. Great article.Really thank you! Want more.

Awesome article post.Thanks Again. Cool.

Very good blog.Really looking forward to read more.

Very neat blog.Much thanks again. Really Cool.

I really liked your blog.Thanks Again. Fantastic.

I value the blog post.Thanks Again. Want more.

Im grateful for the blog post.Really thank you!

Great, thanks for sharing this blog.Really thank you! Awesome.

Major thanks for the article post.

Great article.Really thank you! Cool.

Awesome post.Much thanks again.

Say, you got a nice post.Thanks Again. Keep writing.

I really like and appreciate your article. Awesome.

I really liked your blog post.

Fantastic blog post. Cool.

Great, thanks for sharing this blog.Really looking forward to read more. Really Cool.

I loved your blog.Much thanks again. Will read on…

Very good article post.Really thank you! Cool.

I appreciate you sharing this blog post.Thanks Again.

excellent submit, very informative. I wonder why the other experts of this sector do not notice this. You should continue your writing. I am confident, you’ve a huge readers’ base already!

I’m not sure the place you are getting your info, however good topic.I must spend some time finding out much more or understanding more.Thank you for magnificent info I used to be on the lookout for thisinfo for my mission.

This is one awesome article post.Really thank you! Really Cool.

Thanks

Very informative blog article.Really thank you! Awesome.

Enjoyed every bit of your article. Want more.

A round of applause for your article post. Keep writing.

Very good blog.Much thanks again.

Thankyou for helping out, excellent information.

Tremendous issues here. I’m very satisfied tosee your article. Thank you so much and I am having a look ahead to touch you.Will you please drop me a e-mail?

Really appreciate you sharing this blog article.Thanks Again. Really Great.

Welcome

I value the blog.Much thanks again. Awesome.

Thank you for your blog article.Really thank you! Awesome.

Say, you got a nice blog.Much thanks again. Awesome.

Really informative post.Really thank you! Much obliged.

Thanks so much for the blog article.Really thank you! Really Cool.

I am so grateful for your blog article.Really thank you! Really Cool.

I really like and appreciate your article post.Really thank you! Want more.

Thanks a lot for the article post.

I really liked your article post.Really thank you! Awesome.

Very good article.Much thanks again. Fantastic.

Thanks a lot for the blog article.Thanks Again. Want more.

Wow, great blog post. Will read on…

I am so grateful for your article post. Great.

Appreciate you sharing, great article post.Thanks Again. Great.

Kerassentials are natural skin care products with ingredients such as vitamins and plants that help support good health and prevent the appearance of aging skin. They’re also 100% natural and safe to use. The manufacturer states that the product has no negative side effects and is safe to take on a daily basis.

Very good article post.Thanks Again. Cool.

I loved your blog article.Thanks Again. Will read on…

Really informative article.Thanks Again. Keep writing.

Appreciate you sharing, great blog article.Much thanks again. Really Great.

Wonderful writing! If you’re looking for a passionate writer, I’m available

Hey, thanks for the article.Really thank you! Want more.

I appreciate you sharing this article post.Really looking forward to read more. Really Cool.

Wow, great blog article. Will read on…

Very neat article post. Cool.

A big thank you for your blog post. Really Great.

Appreciate you sharing, great blog post.Really looking forward to read more. Fantastic.

I truly appreciate this blog post.Really thank you! Awesome.