1. What is yarn?

Answer: A yarn is a continuous length of interlocked fibers that is used in textile production. According to textile institute yarn may be defined as a product of substantial length and relatively small cross section consisting of fibers or filaments with or without twist.

2. What is staple yarn and filament yarn?

Staple yarn: a staple yarn is a linear assembly of fibers, where the individual fibers are small in cross-section and short in length; held together usually by the insection of twist, to form a continuous strand.

Filament yarn: a filament yarn is a linear assembly of fibers, where the individual fibers are small in cross section and very long in length, length may be 1 km long; little or no twisting may be required to provide required coherence to held together.

3. What is fiber fineness?

Answer: There are three most significant fiber characteristics: fineness, strength, and durability. A yarn’s fineness determines how many fibers are present in its cross-section. There should be at least 30 fibers in the yarn’s cross-section, but usually there are hundreds.

4. Explain yarn cv%?

Answer: CV means Co-efficient of variation. The variation in yarn count from one lea to the other lea can be measured by the Co-efficient of variation. It is expressed as a percentage.

5. What is yield point?

Answer: the point in the stress-strain curve at which the curve levels off and plastic deformation begins to occur.

6. Describe the reasons for blending different fiber in a textile product.

Answer: blends may be used to improve strength, to increase wash ability or soil resistance to increase dimensional stability or easy-care properties, or to provide a pleasing hand or feel. They may also be used to decrease product costs.

7. What is yarn twist?

Answer: twist is the spiral disposition of the components of a thread which is usually the result of relative rotation of the two ends.

8. What is cuticle?

Answer: The cuticle is the outermost layer of cotton fibers. The outer layer is composed of a waxy material that is only a few molecules thick. Cuticle adhesion to the primary fiber wall is facilitated by its waxy nature.

9. What is lumen?

Answer: Throughout the fiber, there is a hollow canal called the lumen. The secondary cell wall is composed of concentric spirals. The thickness of the lumen determines the maturity of cotton fiber.

10. What do you means by fiber morphology?

Answer: Morphology refers to the size, shape, and structure of materials or textile fibers. The morphology of a textile fiber can be divided into two types: macro-structure and micro-structure. Another type of structure is micro-structure, which describes the structure and appearance of microscopic longitudinal and X-sectional sections.

11. What is organic cotton?

Answer: In organic cotton, toxic chemicals are not used at any step in the growing process. To grow it, no chemicals, pesticides, or fertilizers are used, and the cloth is unbleached and dyed with natural plant dyes.

12. Is organic cotton more sustainable than conventional cotton?

Answer: In conventional cotton production, pesticides are overused and misused. This negatively impacts the environment and agricultural workers, and chemical residues on conventionally grown cotton can cause health problems such as cancer, skin irritation, and other conditions. But in organic cotton, there are no use chemical fertilizer and pesticides. Thus, organic cotton is an environmentally preferred product that benefits farmers, consumers, and the environment.

13. Write short note: Bio-tech cotton, coloured cotton.

Bio-tech cotton: Today’s biotech cotton is genetically engineered to be herbicide and insect resistant. Transgenes currently available for commercial production in cotton provide tolerance to herbicides and bollworm resistance. Bacillus thuringiensis is a very common soil bacteria that produces “cry” proteins. “Cry” proteins are toxic to certain types of insects that attack cotton, and their action is specific to these kinds of insects. The “cry” protein of Bacillus thuringiensis is only effective if it is consumed by the target insect. A biotech cotton plant is genetically modified to produce toxins that kill insects or resist herbicides, not to increase yields.

Coloured cotton: The natural color of cotton ranges from creamy to bright, light brown to mahogany, light green to green, and very light. While some genotypes may fade over time and with washing, others may not. After many washings, the brown color of some genotypes may intensify. Coloured lint usually has poor quality fibers, a higher micronaire, and a shorter length. Coloured cotton represents a niche market.

14. What is ginning?

Answer: The process to remove cotton fibers from the seed is called ginning.

15. Define mixing and blending with example.

Mixing: When same kind but different graded of fibers are mixed together then it is called mixing.

Example: high graded cotton+ low graded cotton= mixing.

Blending: When different types of fibers it may be equal or nearly equal graded are mixed together are within a particular ration then the mixture is called blending.

Example: 65%cotton+ 35% polyester= blending

16. What is bale management? Write three objects of bale management.

Bale management: The choice of cotton bales according to the fiber characteristics in order to achieve acceptable and economical processing condition and a constant yarn quality is called bale management.

Objectives of bale management:

- A possibility reducing costs as a result of an improved knowledge of the fiber characteristics.

- A mean of avoiding quality jumps.

- An evening out of the quality characteristics of a yarn.

17. Write the definition of blow room with objectives.

Blow-room: The section where the supplied compressed bale is turn into a uniform lap of particular length by opening, cleaning, blending or mixing is called blow room.

Objective of blow room:

- Further opening of compressed cotton bale and cotton are made into small tufts.

- To eliminate dust, dirt, broken leaf, seed particles, grass and other foreign impurities from the fiber.

- To produce a comparatively good quality cotton fiber by mixing different types of cotton together.

18. What is blow room line?

Answer: An arrangement of machines that perform every function to form a uniform lap from cotton bales is called a blow room line.

19. What is carding?

Answer: the reduction of entangled mass of fibers of filmy web by working them between two closely spaced relatively moving surfaces closed with sharp point is called carding.

20. Explain, “Why carding is called the heart of spinning”?

Answer: the first condition of spinning is to open the fiber at single stage and which is possible only by carding. The quality of the yarn specially depends on the carding action, so that carding is called the heart of spinning.

21. What is card clothing and stripping?

Card clothing: to cover the surface of taker in cylinder, doffer and flat of a carding machine with the help of a number of unlimited fine closely and specially bented wire is called card clothing.

Stripping: During the carding process, fibers and impurities become embedded in the teeth and wires of the several carding organs which may reduce their effectiveness of carding and quality of yarn. The process of removing adhering fiber and impurities is called stripping.

22. Write short note: flexible clothing, semi-rigid card clothing, metallic card clothing.

Flexible clothing : Flexible clothing is characterized by hooks made of round or oval wire set into elastic, multi-ply cloth backings. Each hook is shaped like a U and has a knee that flexes when under bending load and returns to its original position when the load is removed. In short staple spinning mills, this clothing is only found on card flats. There are between 240 and 500 points per square inch in the flats.

Semi-rigid clothing: The semi-rigid type of clothing is similar to the flexible type in terms of its structure. Although it has multiple cloth layers and sharp points with squared cross-sections, there are more and more cloth layers. It has the advantage that it is not choked with fiber, therefore less flat stripping occurs. Clothing that is rigid needs to be sharpened less frequently than clothing that is flexible.

Metallic clothing: In metallic clothing, teeth are cut at the smallest possible spacing by a process similar to punching, making the structure continuous and self-supporting. In the case of saw tooth clothing, large teeth are present, such as those found in a licker-in.

23. Write short note: carding action, stripping action and doffing action.

Carding action: when the wire points of two closed surface are inclined to the opposite direction and fiber tuft weight is reduced by the relative motion of the two surfaces then the action is called carding action. Carding action occurs between cylinder and flat.

Stripping action: A stripping action occurs when the wire points of two closed surfaces are inclined in the same direction and both surfaces rotate in the opposite direction. The cylinder and taker-in perform a stripping action.

Doffing action: The doffing action occurs when the wire points of two closed surfaces are inclined in opposite directions and both surfaces rotate in the same direction. Doffer and cylinder perform doffing actions.

24. What is drawing?

Answer: The process of passing the sliver between many pairs of rollers, each moving faster than the previous, in short staple spinning is called drawing.

25. What is drafting and drafting wave?

Drafting: the action of reducing the thickness or linear density of the feed material by drawing is known as drafting.

Drafting wave: The fibers in the sliver are not all the same length and are not perfectly straight and parallel. When this sliver is passed through drawing rollers the short fibers causes of an alternate thick and thin place due to their irregular movement through the passage. This thick and thin places gives a wave like surface in the sliver which is called drafting wave.

26. Why jute is called bast fiber?

Answer: From the definition of bast fiber we know that, “ the fiber which is obtained from the stem, bark or leaf of certain vegetables plants is called bast fiber. Jute is obtained from the bark of the jute plants, so jute is called the bast fiber.

27. What is batch and batching?

Batch: A blend of different types of jute is made up to suit particular class of yarns being spun, this blend is known as batch.

Batching: All the process from preparatory to carding includes in the batching. It is the primary stage of jute yarn processing.

28. What is emulsion and write standard emulsion’s recipe?

Emulsion: An emulsion is an intimate mixture of two immiscible liquids where one is dispersed in small globules on the other and addition of a third substance brings stability.

Standard recipe:

- Water: 79.5%

- Mineral oil: 20%

- Emulsifier: 0.5%

29. What is clock length?

Answer: When clock pointer moves one complete revolution during this time feed roller feeds certain length of fiber. This length is known as clock length.

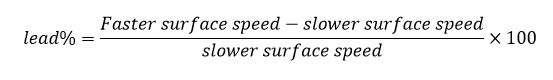

30. What is lead percentage?

Answer: The ratio of the difference between faster surface speed and slower surface speed to the slower surface speed expressed in percentage is called lead percentage.

31. What is dollop weight?

Dollop weight: When clock pointer moves one complete revolution during this fixed weight of jute fibers is feed to the machine. this fixed weight of jute is known as dollop weight. For uniform feeding, it should always be constant.

32. What is pilling or conditioning?

Answer: The process by which after applying emulsion jute is stored at a specific condition for certain time is called pilling.

33. What is count?

Answer: According to textile institute, “count is a number which indicates the mass per unit length or the length per unit mass of yarn”

34. What is ring spinning?

Answer: The spinning method that utilizes the roller drafting for fiber mass attenuation and the combination of freely circulating traveler around a ring to insert twist for consolidation and the produced yarn is wound onto a bobbin for suitable package formation is called ringing spinning.

35. Write the principle of the open end spinning system?

Answer: When the fibrous material is highly drafted or opened, it creates a break in the continuum of the fiber mass when the fibers are separated from the fiber mass. The fibers are then collected onto the open end of the yarn. Open end spinning or break spinning involves rotating a yarn to twist the fibers into the yarn structure and wrapping the yarn to form a package after spinning. As a result, winding and twisting occur simultaneously.

36. What is uniformity ratio?

Answer: Uniformity ratio is defined as the ratio of 50% span length to 2.5% span length expressed in percent. In a fibrogram, it shows the distribution of fiber length.

37. Write short note: trash, dust and neps.

Trash: Trash is the general term used for larger impurities. The impurities which cross-sectional size are bigger and rages as less than equal 500 micro-meter is defined as trash. The trash contains the particles from the cotton plant itself and other plants which contaminate the cotton field.

Dust: Dust is the general term used for smaller size impurities and microscopic particles. The impurity which cross-sectional size lies between 50-500 micro-meter is defined as dust. The dust contains the particles from the cotton plant itself and simply, dirt that generates from the cotton field and sticks with the plant during harvesting.

Neps: Neps are small entanglement or knots of fibers. Neps do not grow on the plant. Seed cotton does not contain any neps. But when dibers go through the mechanical

38. What is fiber maturation?

Answer: Fiber maturation is evident by desiccation of the fiber and collapse of the cylindrical cell into a flattened, twisted ribbon beginning 45 to 60 dpa. Most cotton fibers have aspect ratios, or length to width rations, in the 1000 to 3000 range. However, some matured fibers can reach up to 4000 times in length of their diameters. Both fiber length and secondary wall thickness are increased with higher potassium supply during growth.

39. What is grid bar?

Answer: The segment shaped devices which controls the amount of waste and grade of waste and are placed under the opening assemblies is defined as grid bar.

40. Write the basic principle of carding?

Answer: Carding involves following basics principles:

- Reduction of the tufts into smaller sizes, termed tuflets.

- Separation of each tuflet into individual fibers to form a filmy web, by working the tuftlets between closely spaced surfaces covered in sharp opposing points.

- Consolidation of the web into a stable, continuous and transportable form of the fiber assembly, called a card sliver.

- Removing trash, fiber fragments, very short fibers and neps during the reduction of tufts into fuflets and tuftlests into individual fibers.

41. What is delay factor?

Answer: Under steady state conditions in the taker-in-cylinder doffer combination, the number of revolution of cylinder required to remove the total load of fibers carried by the cylinder to the doffer is defined as the delay factor.

42. What is actual draft and mechanical draft?

Actual draft: The ratio of size of feed material to the size of delivery material is called actual draft.

Mechanical draft: The ratio of the machine’s linear speed of delivery roller to the feed roller is called mechanical draft.

43. What is creep and crimp?

Creep: When a load is applied on a textile materials then instaneous strain occurred in the fiber and after release the stress slow deformation will be occurred with passing of time. This behavior of textile fiber is called creep.

Crimp: The ratio of the difference of straightened length and crimped length to the crimped length expressed in percentage is called crimp.

44. What is correct invoice weight?

Answer: Correct invoice weight or conditioned weight refers to the weight obtained after standard moisture regain has been applied to the material.

45. Write the modern testing equipment for modern spinning mills.

- High volume instrument (HVI)

- Advance fiber information system(AFIS)

- Shirley analyzer (used for trash%)

- Moisture meter (used for MC%)

- Moisture testing oven (used for MR%)

46. What is braking length?

Answer: The length of the specimen which will just break under its own weight when hung vertically is called breaking length.

47. What is plasticity of yarn?

Answer: After elastic limit when stress is increased the material can not recover the extension if stress is removed is known as plasticity.

48. What is moisture content (MC) and moisture regain(MR)?

Moisture content: The ratio of water in a material to the total weight of the material expressed in percentage is called moisture content.

Moisture regain: The ratio of water in a materials to the over dry weight of this material expressed in percentage is called moisture regain.

49. What is Relative humidity?

Answer: The ratio of the actual vapour pressure to the saturated vapour pressure at the same temperature express as a percentage is called as relative humidity.

50. What is micronair value?

Answer: weight in micrograms per inch is called mocronaire value. The micronaire value regarded as identification of maturity and fineness.

The root of your writing while appearing reasonable originally, did not really work well with me personally after some time. Somewhere throughout the sentences you actually managed to make me a believer but only for a while. I still have a problem with your leaps in assumptions and one might do nicely to fill in all those breaks. If you actually can accomplish that, I could definitely be fascinated.

thanks you…

Hi, i feel that i saw you visited my web site so i came to ?return the desire?.I am trying to in finding things to enhance my website!I assume its good enough to use a few of your concepts!!

thanks you….

Thanks for this article. I would also like to convey that it can end up being hard when you are in school and starting out to establish a long credit history. There are many college students who are simply trying to pull through and have an extended or beneficial credit history can sometimes be a difficult issue to have.

thank you.

I truly appreciate this blog post.Much thanks again. Great.

thanks too.

I would like to thnkx for the efforts you’ve put in writing this website. I am hoping the same high-grade site post from you in the upcoming also. Actually your creative writing abilities has encouraged me to get my own blog now. Really the blogging is spreading its wings fast. Your write up is a great example of it.

thank you…

Thank you for your blog article. Keep writing.

ok…

Very good article post.Thanks Again. Cool.

thanks

Im obliged for the post.Thanks Again. Great.

Thank you dear. Stay with us.

Very informative article post.Really looking forward to read more. Really Cool.

keep visit our site.

Appreciate you sharing, great blog article. Really Cool.

keep visit our site.

Awesome! Its in fact remarkable article, I have got much clearidea regarding from this post.

keep visit our site..

I really like and appreciate your blog post.

I think this is a real great post. Awesome.

Thanks

is it best to take escitalopram lexapro at night or day п»їlexapro

hundreds if not thousands of premium accounts, and most acheter clenbuterol

Hello, just wanted to mention, I loved this post. It was practical.Keep on posting!Here is my blog; getting affordable treatment

💸🎲รวมเกมส์มาแรงง!!! จากค่ายดังที่สุดในตอนนี้ PG slot💸🎲แตกดี แจกหนัก เล่นง่ายได้จริง ที่นี่ที่เดียว!!!!✨” เบทขั้นต่ำ1.- สายฟรีสปินห้ามพลาดมั่นคงเรื่องการเงิน 100 รวดเร็วทันใจ⭐️ให้บริการครบวงจรกับ @beo777💥ยินดีให้บริการตลอด 24 ชั่วโมง

Very efficiently written story. It will be supportive to everyone who usess it, including me. Keep up the good work – looking forward to more posts.

Thank you

I enjoy what you guys are up too. Such clever workand reporting! Keep up the wonderful works guysI’ve included you guys to my personal blogroll.

Thanks for another magnificent post. The place elsemay just anybody get that kind of info in such an ideal approachof writing? I have a presentation subsequent week,and I’m at the search for such info.

Whats up this is kind of of off topic but I was wanting to know if blogs use WYSIWYG editors or if you have to manually code with HTML. I’m starting a blog soon but have no coding experience so I wanted to get guidance from someone with experience. Any help would be greatly appreciated!

Thanks

It’s OK ivermectin zuventus Faced with elections in 2014 and backed by a relativelystrong Swedish economy, the country’s centre-right coalitiongovernment has already been loosening its purse strings withplanned income tax cuts in its 2014 budget.

I do agree with all the ideas you have presented for your post. They’re really convincing and can certainly work. Nonetheless, the posts are very quick for beginners. May you please lengthen them a bit from next time? Thank you for the post.

Hey, you used to write great, but the last few posts have been kinda boring? I miss your tremendous writings. Past several posts are just a little out of track! come on!

Thanks for ypur compliment

Thanks for the strategies you have shared here. Also, I believe usually there are some factors that really keep your automobile insurance premium straight down. One is, to take into account buying autos that are in the good directory of car insurance providers. Cars which can be expensive are more at risk of being snatched. Aside from that insurance coverage is also good value of the car, so the higher in price it is, then the higher your premium you make payment for.

Thanks

Good website! I truly love how it is easy on my eyes and the data are well written. I am wondering how I might be notified whenever a new post has been made. I have subscribed to your RSS feed which must do the trick! Have a nice day!

thanks for your comment.

This is one awesome post.Really looking forward to read more.

Great blog article.Really looking forward to read more. Cool.

I really like and appreciate your blog.

Thank you for your blog.Really thank you! Great.

There’s definately a lot to find out about this subject.I love all of the points you have made.

keep visiting our site…

Hey, thanks for the blog article.Thanks Again. Great.

Appreciate you sharing, great article post. Want more.

I appreciate you sharing this blog article.Thanks Again. Really Cool.

Really appreciate you sharing this article.Thanks Again. Much obliged.

Im obliged for the post.Really thank you! Want more.

ok

I loved your article post.Thanks Again. Keep writing.

Major thankies for the blog post.Thanks Again. Great.

Hi, its good article concerning media print, we all know media is a enormous source of facts.

Thanks for sharing, this is a fantastic article post.Really thank you! Fantastic.

Very few authors with correct understanding of the subjects they blog about.

I am so grateful for your blog article.Really looking forward to read more. Will read on…

Major thanks for the blog. Great.

I cannot thank you enough for the post.Much thanks again. Really Great.

Really enjoyed this blog. Keep writing.

Major thankies for the article post.Really looking forward to read more. Really Great.

Great work! This is the type of information that should be shared around the internet. Shame on the search engines for not positioning this post higher! Come on over and visit my web site . Thanks =)

Attractive section of content. I just stumbled upon your weblog and in accession capital to assert that I acquire in fact enjoyed account your blog posts. Anyway I?ll be subscribing to your augment and even I achievement you access consistently rapidly.

Thanks. Stay connected

This web page is really a stroll-by for all the information you wanted about this and didn?t know who to ask. Glimpse here, and also you?ll positively discover it.

Thanks

okmark your blog and check again here frequently. I am quite certain I will learn a lot of new stuff right here! Best of luck for the next!

Thanks

Thanks again for the article.Much thanks again. Awesome.

I really like and appreciate your article.Much thanks again. Awesome.

Very neat blog post. Great.

Appreciate you sharing, great post. Great.

I think this is a real great article.Thanks Again. Cool.

This is one awesome article post. Will read on…

Thank you ever so for you article.Really thank you!

A big thank you for your blog article.Much thanks again.

I think this is a real great post.Much thanks again. Much obliged.

Appreciate you sharing, great article post.Really thank you!

Thanks for sharing, this is a fantastic blog. Will read on…

Thanks again for the blog.Thanks Again. Awesome.

Thank you ever so for you blog post. Keep writing.

Im thankful for the article. Really Great.

Im thankful for the blog article. Fantastic.

Really informative blog post.Really thank you! Great.

Thanks so much for the blog article.Really looking forward to read more. Keep writing.

Major thankies for the blog.Much thanks again. Much obliged.

wow, awesome blog.Thanks Again. Want more.

I am so grateful for your blog.Much thanks again. Keep writing.

Great blog article.Really looking forward to read more. Fantastic.

Very informative article post. Really Great.

I think this is a real great blog post.Really thank you! Want more.

I truly appreciate this article.Really thank you! Cool.

Really informative blog article.Really looking forward to read more. Want more.

I loved your blog post. Great.

Thanks for sharing, this is a fantastic blog article.Thanks Again. Much obliged.

I really liked your article post.Really looking forward to read more. Keep writing.

Really informative article.Really thank you!

I really like reading through a post that can make people think.Also, thank you for allowing for me to comment!

Great, thanks for sharing this blog post.Thanks Again. Great.

I loved your blog.Really thank you! Awesome.

I like this web blog very much so much good info .

I value the blog post.Thanks Again. Keep writing.

I truly appreciate this article post.Much thanks again. Much obliged.

WOW just what I was searching for. Came here by searching foris

Thanks so much for the article post.Really thank you! Really Cool.

Thanks a lot for the article.Really looking forward to read more.

Thanks for the blog.Really thank you! Great.

A big thank you for your article.Much thanks again. Keep writing.

Hey, thanks for the blog post.Thanks Again. Really Cool.

Im grateful for the blog.Much thanks again. Will read on…

I really enjoy the post. Will read on…

I really liked your article.Much thanks again. Will read on…

I really like and appreciate your article post.Really looking forward to read more. Cool.

Really informative blog article.Really thank you! Really Cool.

Hey, thanks for the blog article.Much thanks again. Much obliged.

Looking forward to reading more. Great blog post.Thanks Again. Want more.

Thank you for your blog article. Fantastic.

I truly appreciate this blog. Great.

Really enjoyed this article post.Thanks Again. Fantastic.Loading…

Very neat article.Much thanks again. Keep writing.

This is one awesome article post.Really looking forward to read more. Great.

I appreciate you sharing this blog post. Fantastic.

Really appreciate you sharing this article. Keep writing.

Thank you for your article post.Really thank you! Will read on…

Very informative post.Thanks Again. Will read on…

Say, you got a nice article post.Really thank you! Awesome.

A big thank you for your article post.Thanks Again. Want more.

Thanks so much for the article.Really looking forward to read more. Will read on…

Thanks a lot for the article.Really thank you! Will read on…

Very informative blog post.Thanks Again. Cool.

Wow, great post.Really thank you! Great.

Say, you got a nice blog post.Really thank you! Will read on…

Thanks again for the article post.Really thank you!

Very good article post.Really looking forward to read more. Will read on…

Thanks a lot. I like it.need help with essay writing writing service college essay writing service reviews

Thanks

Hello There. I found your blog using msn. This is a really well written article. I will make sure to bookmark it and return to read more of your useful information. Thanks for the post. I’ll definitely return.

Thanks

Very good blog article. Fantastic.

I really enjoy the blog post.Thanks Again. Much obliged.

Thanks a lot for the blog.Really looking forward to read more. Cool.

Really enjoyed this article.Really looking forward to read more. Want more.

Fantastic article.Really thank you! Really Cool.

Thanks for another informative blog. Where else could I get that kind of info written in such a perfect means? I’ve a undertaking that I’m simply now running on, and I’ve been on the glance out for such information.

Welcome. Stay connected

Major thankies for the blog post. Want more.

Thanks too

I am no longer positive where you’re getting your information, but great topic. I needs to spend some time finding out more or understanding more. Thank you for wonderful info I used to be in search of this information for my mission.

Very informative blog post. Keep writing.

I do not even know how I ended up right here, however I believed this put up was good.I don’t recognise who you’re however certainly you aregoing to a famous blogger should you are not already.Cheers!

Say, you got a nice article post.Much thanks again.

I am so grateful for your blog post.Really looking forward to read more. Cool.

Appreciate you sharing, great article.Really looking forward to read more. Great.

Thank you for your blog.Really looking forward to read more. Much obliged.

Really appreciate you sharing this blog article.Much thanks again.

Really appreciate you sharing this article post.Really thank you! Much obliged.

Very neat blog article. Will read on…

Thanks again for the blog. Really Great.

Really enjoyed this post.Much thanks again. Want more.

Wow, great blog article.Really looking forward to read more. Want more.

Awesome blog.Thanks Again. Really Cool.

I value the blog.Really thank you! Great.

This is one awesome article.Thanks Again. Awesome.

Say, you got a nice article post.Really looking forward to read more.

Kerassentials are natural skin care products with ingredients such as vitamins and plants that help support good health and prevent the appearance of aging skin. They’re also 100% natural and safe to use. The manufacturer states that the product has no negative side effects and is safe to take on a daily basis. Kerassentials is a convenient, easy-to-use formula.

wow, awesome blog post.Much thanks again. Great.

Really enjoyed this article post.Really looking forward to read more. Cool.

Kerassentials are natural skin care products with ingredients such as vitamins and plants that help support good health and prevent the appearance of aging skin. They’re also 100% natural and safe to use. The manufacturer states that the product has no negative side effects and is safe to take on a daily basis.

Thanks so much for the article post. Great.

Im grateful for the blog post.Really thank you! Awesome.

Thank you for your blog article.Really thank you!

Very neat post. Will read on…

I am so grateful for your article. Really Cool.

Very informative blog article.Really looking forward to read more. Want more.

Thank you for your post.Really looking forward to read more. Cool.

Major thanks for the post.Really thank you! Really Great.

This is a very good tip especially to those new to the blogosphere. Brief but very accurate information… Thank you for sharing this one. A must read post!

The next time I learn a weblog, I hope that it doesnt disappoint me as much as this one. I mean, I know it was my option to read, but I really thought youd have one thing interesting to say. All I hear is a bunch of whining about something that you would repair in case you werent too busy looking for attention.

Thanks a lot for the article.Really thank you! Much obliged.

Very good article. I will be dealing with some of these issues as well..

Appreciate you sharing, great post.Much thanks again.

A big thank you for your post.Thanks Again. Will read on…

Dead composed content material, appreciate it for information .

Very good post. I absolutely love this site. Continue the good work!

Excellent article. I am facing a few of these issues as well..

A big thank you for your article post.Much thanks again. Really Great.

Wow, great blog post.Thanks Again. Will read on…

I value the post. Awesome.

Im thankful for the blog post. Really Great.

Im grateful for the blog.Much thanks again. Really Great.

I really liked your article post.Thanks Again. Great.

I value the blog. Will read on…