Introduction:

The shearing process is a critical step in the textile industry that involves the removal of excess fibers from the surface of a fabric. This process is essential in achieving the desired texture, appearance, and performance of the final textile product. In this article, we will discuss the shearing process and its chemistry in the textile industry.

What is Shearing Process?

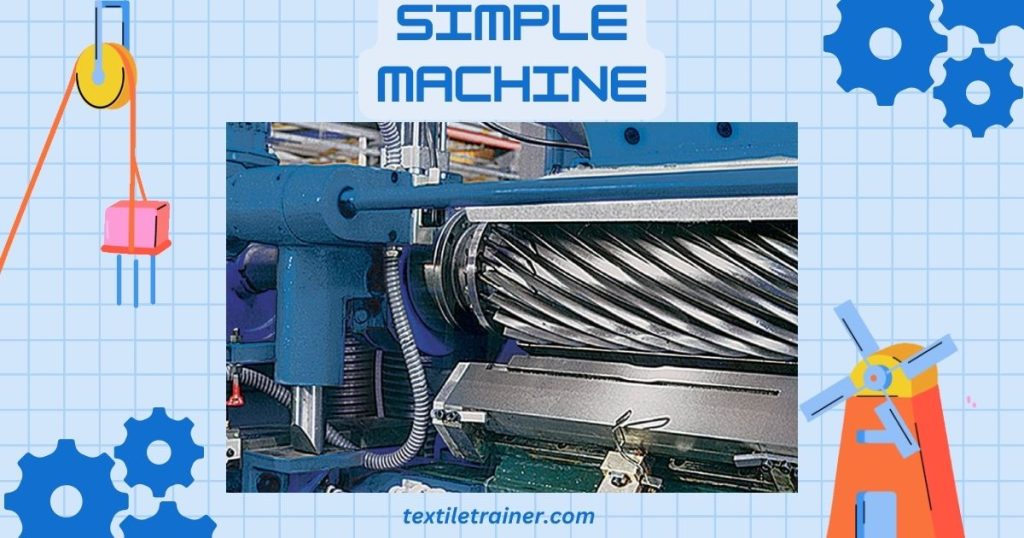

Shearing is a process where excess fibers are removed from the surface of a fabric. It is done using a machine called a shearing machine or a shearing blade. The shearing machine has a revolving cylinder with a blade, which is used to cut the fibers from the surface of the fabric. The blade is adjusted to achieve the desired level of shearing.

The shearing process is an important step in finishing textile products. It helps to remove any loose fibers that may cause pilling and fuzzing. It also helps to improve the texture and appearance of the fabric.

The Chemistry of Shearing

The shearing process involves a complex chemical reaction between the fibers of the fabric and the blade of the shearing machine. When the blade cuts through the fibers, it generates heat due to friction, which causes the fibers to melt slightly. This helps to create a smooth surface.

The frictional force generated during the shearing process also causes the fibers to break. The broken fibers create a halo effect around the sheared area, which helps to improve the appearance of the fabric.

The chemistry of the shearing process is also affected by the type of fibers used in the fabric. Natural fibers, such as cotton, wool, and silk, have different chemical properties than synthetic fibers, such as polyester and nylon. The type of fibers used in the fabric can affect the level of shearing required and the results of the shearing process.

Types of Shearing Process

The shearing process can be done using a variety of techniques, including mechanical shearing, chemical shearing, and electrostatic shearing.

Mechanical Shearing

Mechanical shearing involves the use of a machine with a revolving cylinder and a blade that cuts through the fibers of the fabric. The blade is adjusted to achieve the desired level of shearing. Mechanical shearing is the most common type of shearing used in the textile industry.

Chemical Shearing

Chemical shearing involves the use of chemicals to dissolve the excess fibers from the surface of the fabric. This technique is used when mechanical shearing is not suitable or when the fabric is delicate and cannot withstand the force of a shearing machine.

Electrostatic Shearing

Electrostatic shearing involves the use of an electric field to remove the excess fibers from the surface of the fabric. This technique is used when a very fine level of shearing is required or when the fabric is very delicate and cannot withstand the force of a shearing machine.

Applications of Shearing

The shearing process has various applications in the textile industry. One of the primary applications of shearing is in the production of upholstery fabrics. Upholstery fabrics require a high level of shearing to achieve a smooth and uniform texture that can withstand wear and tear.

Shearing is also used in the production of clothing, bedding, and other textiles. The level of shearing required depends on the type of fabric and the desired final product.

Benefits of Shearing

The shearing process offers several benefits to the textile industry. One of the main benefits is that it helps to improve the texture and appearance of the fabric. By removing excess fibers, the fabric becomes smoother and more uniform, which makes it more attractive and easier to work with.

Shearing also helps to reduce the risk of pilling and fuzzing, which are common problems in textiles. Pilling occurs when the fibers of the fabric become tangled and form small balls on the surface. Fuzzing occurs when the fibers of the fabric become loose and form small fibers on the surface.

Another benefit of shearing is that it can improve the functionality of the fabric. By removing excess fibers, the fabric becomes more breathable, which can be beneficial for products such as bedding and clothing.

Conclusion:

The shearing process is an essential step in the textile industry that helps to achieve the desired texture, appearance, and performance of the final product. The chemistry of the shearing process involves a chemical reaction between the fibers of the fabric and the blade of the shearing machine. The type of fibers used in the fabric can affect the level of shearing required and the results of the shearing process. Shearing is an important aspect of textile manufacturing, and understanding its chemistry is crucial in achieving the desired results.

Im grateful for the blog.