Flame Retardant Finishing Recipe for Textile Made Easy

Introduction

Flame retardant (FR) finishing is the most important functional finish for textile materials. Because it is linked to human safety. Textile materials catch fire quickly when ignited by a source burn. Hence, it can be hazardous to the environment. By applying an efficient flame retardant to the same textile material, flame propagation is stopped. The fire is extinguished after the ignition source is removed. It is important to determine the limiting oxygen index (LOI) owing to determine flammability. Limiting oxygen index (LOI) indicates the minimum oxygen concentration in the oxygen-nitrogen mixture required to support candle-like combustion.

You May Read: Button Pull Testing for Garment Safety explained in a Simple Way

What is flame retardant finishing?

Flame retardant finishing is a chemical treatment applied to the fabric to protect the fabric from fire. In other words, flame retardant finishing is a chemical finish that resists easy catching of fire in fabric as well as spreading it too.

What is LOI (Limiting Oxygen Index)?

The limiting oxygen index (LOI) is the minimum concentration of oxygen in an oxygen-nitrogen mixture that is necessary for flaming combustion to occur. It is expressed in volume percent (vol%). It was first introduced in 1966 by Fenimore and Martin and is used to indicate the relative flammability of materials. A higher LOI means lower flammability and a lower LOI means higher flammability.

| LOI <21% | Textile materials can catch fire readily and burn in an ambient atmosphere. |

| LOI between 21-27% | Textile materials also catch fire but they burn slowly in the ambient air. |

| LOI>27% | Generally considered as flame retardant materials. |

Thermal transition temperatures and limiting oxygen index of different fibers are given below:

| Fiber | Glass transition (Tg) 0C | Pyrolysis Temp (Tp) 0C | Melting Temp(Tm) 0C | Combustion Temp. (Tc) 0C | LOI% |

| Cotton | – | 350 | – | 350 | 18-18.5 |

| Wool | – | 245 | – | 600 | 23.6-25 |

| Viscose | – | 350 | – | 420 | 18.9 |

| Polyester | 70-90 | 420-450 | 255 | 480 | 20-21 |

| Polypropylene | -20 | 469 | 165 | 550 | 18.6 |

| Acrylic | 100 | 250 | >220 | 290 | 18.2 |

| Nylon 6 | 47-50 | 431 | 215 | 460 | 20-21.5 |

| Nomex | 275 | 410 | 375 | >500 | 29-30 |

| Kevlar | 340 | >550 | 560 | >590 | 29 |

Flame Retardant Mechanism

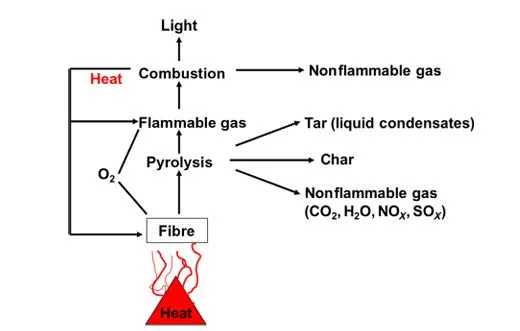

The mechanism for imparting flame retardant to a textile material is easily understood by studying the fibre combustion process. If one can understand the mechanism of the combustion process of a textile material, they can easily understand the mechanism of flame retardant finishing process.

Combustion requires three components (heat, oxygen, and fuel) for an exothermic process. It is self-catalytic and continues until the heat, oxygen, and fuel are exhausted. In the presence of heat, any textile material will reach the pyrolysis temperature (Tp). The pyrolysis process generates flammable gases, such as hydrogen, carbon monoxide, and tar (liquid condensates). It also produces nonflammable gases such as water vapour, carbon dioxide, higher oxides of sulfur and nitrogen, and carbon char. They burn rapidly when these flammable gases come into contact with oxygen. It is also releasing heat energy. As a result, a continuing rise in temperature helps the fibre to reach its combustion temperature (Tc). The combustion temperature (Tc) generated heat accelerates the polymer’s pyrolysis. It is also generating more flammable gases. Hence, it is driving the intense combustion process.

The flame-retardant finish prevents the attainment of the pyrolysis temperature. It also suppresses the combustion and decreases the burning surface temperature. It also limits the production of combustible gases, which prevents flame propagation. In a sample word, the flame retardant finishing process slows down the combustion process. Hence, flame retardant finished textile materials burn slowly.

Types of Flame Retardant

Flame retardant chemicals may be classified in many ways. But, if we combine all classifications, we find three types. The three major types of flame retardants are inorganic, organic and biobased.

- Inorganic FR: Inorganic fire resistant is endothermic and includes high security, color volatilization, low smolder harmfulness, and low cost. Example: Borax, Boric acid, Ammonium sulfate(NH4SONH2), ammonium bromide (NH4Br), and magnesium slats.

- Organic FR: Organic flame retardants are two types: halogen FR, and organophosphorus FR.

- Halogen FR: Halogen FRs produce an outer layer of heavier-than-air haloids acid that dilutes ambient air or isolates fresh air. Consequently, halogen FRs can be easily distinguished from fresh air over time.

- organophosphorus FR: P-C bonds are found in organophosphorus compounds that are used increasingly as FR additives due to their ease of synthesis and excellent thermal and hydrolytic stability.

- Biobased FR: Biobased flame retardant is becoming popular day by day as a functional finishing of textile materials. It can be classified into two categories.

- Plant-based bio-FR: Plant-based FRs are extracted from different types of plants. Example: Green coconut shell extract, banana pseudostem sap, spinach juice, and starch.

- Animal-Based Bio-FR: Animal based FRs are collected from animal organs. Example: Chicken feather, hydrophobin, casein, whey protein, deoxyribonucleic acid, and chitosan.

Latest Flame Retardant Technology

The following technologies have shown promising results in achieving superior flame-proof quality and quantity in recent times.

- Microcapsule FR technology

- Surface modification technology

- Cross-linkage technology

- Nanometer FR Technology

- Superfine melt technology

- Smoke abatement technology

- Macromolecule technology

Recipe for Flame Retardant Finishing

The following is the typical recipe for flame retardant finishing for cotton fabric.

| Chemical | Amount |

| Tetrakis (hydroxymethyl) phosphonium chloride (THPC) | 20% (on the weight of fabric) |

| Urea | 10% (on the weight of fabric) |

| Methylol Melamine | 10% (on the weight of fabric) |

| Tri-ethanolamine | 3% (on the weight of fabric) |

| M:L | 1:40 |

| Fabric (13.5×3.5 inch) | 10 gm |

Procedure

- Initially, woven fabric (13.5×3.5 inch) is cut by using scissors and weighted the fabric.

- Now, all chemicals are weighted according to the weight of fabric and make the solution.

- Then, fabric is dipped into the solution for 10 min.

- The next step, fabric is padded. (two dip to nip- when complete first time padding then dip the sample again into the solution and again padding the fabric)

- Finally, fabric is dried in oven at 1400 C for 5 minutes.

Flame Retardant Effect Testing Method

There are many testing methods for grading the fireproof scale of textile materials. The following are some flame retardant effect testing methods available:

- LOI

- Thermal analysis of the FR finish

- Micro combustion calorimeter (MCC)

- Fire spread

Advantages of Flame Retardant

- Flame-retardant finished fabric burns slowly and slower flame spread.

- It has better performance for high risk work environments.

- It also improves protection for home and medical textiles.

Disadvantages of Flame Retardant

- Some FR agent reduces fabric strength.

- Hand feel of FR finished fabric may become stiffer.

- All FR finishes are not fully wash durable.

Conclusion

A flame retardant finish makes fabric safer. Flame retardant finishing process behaviors of fabric against fire. It reduces flammable gases and slows flame spread. If you have any question about flame retardant finishing process, let me know below comment box.

FAQs

- Which flame retardants are most common for cotton fabric?

- Phosphorus and phosphorus-nitrogen are most common used for cotton fabric.

- Does the FR finish change fabric feel?

- Yes, FR finished fabric may create a slightly stiff hand feel.

- Is the FR finished fabric safe for skin contact?

- It depends on the chemical brand. Approved FR chemicals are tested for safe and compatible for skin.

Reference

- Hollingbery, L. A., & Hull, T. R. (2010). Thermochimica Acta The thermal decomposition of huntite and hydromagnesite — A review ଝ. 509, 1–11. https://doi.org/10.1016/j.tca.2010.06.012

- Kakar, P., Singh, A., & Sheikh, J. (2023). Flame retardant finishing of textiles – A comprehensive review. 48(December), 475–494. https://doi.org/10.56042/ijftr.v48i4.7662

- Mazumder, N., & Islam, M. T. (n.d.). Flame Retardant Finish for Textile Fibers. 373–406.

- Pandit, P., Singha, K., Kumar, V., & Maity, S. (2020). Advanced flame-retardant agents for protective textiles and clothing. In Advances in Functional and Protective Textiles. LTD. https://doi.org/10.1016/B978-0-12-820257-9.00016-3