Lotus fiber manufacturing process explained simply with 9 Steps

Introduction

Lotus fiber is a natural fiber extracted from the stem of the lotus plant. The Lotus fiber manufacturing process is simple, but the production rate is very low. Production is mostly done by hand. Hence, lotus fiber is rare. It is usually produced in small quantities in countries such as Myanmar and parts of Southeast Asia. It is also called lotus silk because of its soft and smooth feel. Lotus silk is fully biodegradable as it is plant-based. Lotus fiber fabric is light, breathable, and comfortable to wear.

You may Read: Flame Retardant Finishing Recipe for Textile Made Easy

Why is lotus fiber manufacturing important?

The Lotus fiber manufacturing process supports a sustainable textile process. The raw material comes directly from lotus stems. It grows naturally in water. The extraction process does not require heavy chemical treatment. It does not impact on environment. Additionally, lotus fabric has good moisture absorption and a soft touch similar to silk. Hence, it is also called lotus silk. It is suitable for warm climates because it allows air to pass easily through the fabric. On the other hand, buyers as well as consumers show more interest in Eco-friendly textiles. Lotus fiber gains attention as a natural alternative material. Hence, lotus fiber manufacturing is important.

Lotus Fiber Chemical Components

Chemical components of lotus fiber is given below:

| S/N | Components | Amount(%) |

| 1.0 | Cellulose | 68.04 |

| 2.0 | Hemi-cellulose | 9.36 |

| 3.0 | Lignin | 8.76 |

| 4.0 | Pectin | 3.2 |

| 5.0 | Fat waxy | 3.1 |

| 6.0 | Ash | 2.9 |

| 7.0 | Hypertrophy | 2.74 |

| 8.0 | Other | 1.9 |

The 17 kinds of amino acids found in lotus fiber amount to 1.94%, of which seven kinds are essential for the body, including leucine 0.134%, lysine 0.078%, phenylalanine 0.083%, threonine 0.083%, methionine 0.036%, isoleucine 0.085%, valine 0.036%, except for tryptophan. Lotus fiber contains positive amino acids, which are associated with the skin and are healthy for the body since the main composition of the body is derived from amino acids.

| S/N | α – amino acid | Amount(%) |

| 1.0 | Asp | 0.213 |

| 2.0 | Theronine | 0.083 |

| 3.0 | Serine | 0.171 |

| 4.0 | Glutamic acid | 0.227 |

| 5.0 | Proline | 0.088 |

| 6.0 | Glycine | 0.321 |

| 7.0 | Ala | 0.121 |

| 8.0 | Cystine | 0.015 |

| 9.0 | Valine | 0.036 |

| 10 | Methionine | 0.036 |

| 11 | Isoleucine | 0.085 |

| 12 | leucine | 0.134 |

| 13 | Tyrosine | 0.137 |

| 14 | Phenylalanine | 0.083 |

| 15 | Lysine | 0.078 |

| 16 | Histidine | 0.038 |

| 17 | Arginine | 0.075 |

Lotus Fiber Properties

| S/N | Parameter | Value |

| 1.0 | Linnear density (dtex) | 25.9 |

| 2.0 | Relative strength (cN/dtex) | 1.68 |

| 3.0 | Relative strength variation coefficient | 46.8 |

| 4.0 | Break elongation (%) | 6.68 |

| 5.0 | Whiteness (%) | 42.9 |

| 6.0 | Fiber length | 26-60 mm (after extraction) |

| 7.0 | Moisture regain (%) | 8-12 |

| 8.0 | Color | Cream to light brown |

| 9.0 | Luster | Low to moderate |

| 10 | Thermal behaviour | Buns like cellulose |

| 11 | Biodegradability | Fully biodegradable |

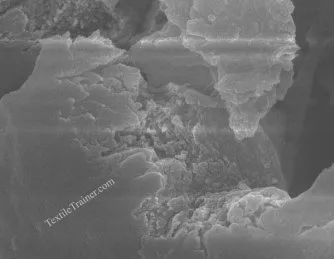

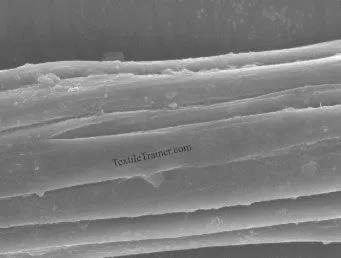

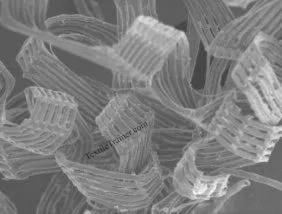

Micro-morphology of lotus fiber

The morphology of lotus monofilament fibers in cross section is similar to a circle. The monofilament fibers in the longitudinal tube of the lotus stalk are tightly associated and exhibit a spiraling revolving structure. During stretching with physical force, the spiral revolving level will be weakened, and the association within lotus monofilament fibers will be broken, resulting in a small cross section of lotus fiber and a complex shape formed by many monofilament fibers, such as a circle and half moon.

In longitudinal directions, monofilament fibers have smooth surfaces and a diameter of around 4 m. In longitudinal directions, there are cross striations, and in axial directions there are nodes, where monofilament fibers associate. Identical to the determination of chemical components, some sticky things, mainly polysaccharides, attach to the fiber surface.

According to SEM observations of lotus fiber surface morphology, ribbon spiral revolving and revolving number are closely correlated to variety, growing conditions, harvest season, extraction place, and extraction method. Observing the surface morphology of lotus culms further by extracting fiber from the top, central, and root, it was found that the fiber at the top is soft and slim, with a ribbon spiral revolving with large curvatures and a large quantity, similar to a spring belt. Root fibers are short and rough, with little spiral revolving, as if they were clavate through monofilament fibers handing together tightly, whereas central fibers are in a middle state. Due to its unique spiral revolving structure, its product provides excellent moisture absorption and permeability.

You may read: Button Pull Testing for Garment Safety explained in a Simple Way

Lotus Fiber Manufacturing Flow-chart

1. Harvesting of lotus stems

Initially, farmers collect fresh lotus stems from ponds or lakes. The seams must be green and healthy. Fresh stems give better fiber. The work is done by hand in water.

2. Sorting and Cutting

After harvesting, lotus stems are cleaned. Bad or damaged stems are removed. Good steams are cut into small pieces. Usually, each piece is 15-20 cm long.

3. Breaking the Stem

Workers gently break each stem piece. They bend it carefully. Inside the stem, thin sticky fibes apppear. These fibers are very fine.

4. Fiber Extraction (Pulling)

Now, the worker slowly pulls the fibers out. Several fine filaments come out together. This step needs skill and patience. It is labor-intensive work. If the pulling is not smooth, the fiber breaks.

5. Fiber Twisting and Joining

The pulled fibers are twisted together by hand. New fibers are added continuously. The worker joins them smoothly. This makes a long, continuous yarn. The twisting must be even.

6. Drying of Yarn

Subsequently, the fresh yarn is wet and soft. It is placed in the air to dry. Drying makes the yarn stronger. Direct strong sunlight is avoided.

7. Spinning

The dried fiber is further twisted on a simple spinning device. This makes the yarn stronger and smoother. The yarn becomes ready for weaving.

8. Weaving

The yarn is woven on a handloom. Weaving is low because lotus yarn is delicate. Skilled weavers handle it carefully.

9. Finishing

The fabric is washed gently. No heavy chemicals are used. Sometimes natural dye is applied. The fabric is then dried and pressed.

Use of Lotus Fiber

Lotus fiber is used to produce soft and light fabric. Common products include:

- Scarves

- Shawls

- Stoles

- Traditional garments.

- Meditation and spiritual clothing

Lotus fabric feels cool in summer and warm in mild weather.

Limitations of the lotus fiber

- The production rate of lotus fiber is very slow.

- Large-scale industrial production is difficult.

- The cost is high compared to other fibers.

- Fiber yield from each stem is very low.

- Raw material availability depends on the season.

Because of these limitations, lotus fabric remains rare and expensive.

Conclusion

Lotus fiber manufacturing is a traditional and manual process. It starts from harvesting lotus stems and ends with handwoven fabric. The fiber is natual, biodegradable, and comfortable. Though production is slow, but the final fabric is unique and eco-friendly.

FAQs about lotus fiber manufacturing

- What is lotus fiber made from?

- Lotus fiber is made from the stem of the lotus plant. The fine filaments inside the stem. The fiber is extracted by hand. After extracting, fibers are twisted into yarn.

- Why is lotus fabric expensive?

- Production of lotus fiber is slow. Extraction process is done mostly by hand. Additionally, fiber yield from each stem is very low. Beside, skilled labor is needed at every stage. Thus lotus fabric is expensive.

- Where is lotus fiber mainly produced?

- It is mainly produced in Myanmar and some parts of Southeast Asia.

- What is lotus fiber used for?

- Lotus fiber is very durable and water-resistant fiber. Thus it is used for curtains, upholstery. It also used for Meditation and spiritual clothing. Beside, lotus fabric are used in making home décor products. It gives a natural and rich feel to the living space.

Reference

- Aishwariya, S., & Thamima, S. (2019). Sustainable textiles from lotus. 28(10).

- Chen, D., Gan, Y., & Yuan, X. (2012). Research on structure and properties of lotus fibers. 478, 1948–1954. https://doi.org/10.4028/ www.scientific.net/AMR.476-478.1948

- Zhang, H., & Li, Y. (2010). Lotus Fiber Production and its Property. Advanced Materials Research, 146–147, 93–96. https://doi.org/10.4028/www.scientific.net/AMR.146-147.93