Introduction:

A proverb says “Card is the heart of the spinning mill” and “Well carded is half spun”. These proverbs illustrate the importance of carding in spinning. Carding is the process of reducing entangled fibers to filmy webs by working them between two closely spaced relatively moving surfaces closed with sharp points. The carding machine is located between the blow room and the drawing frame in the spinning process. Carding can also be used to create mixes of different fibers and colors. By carding, fiber is thinned out evenly and distributed along a roll, facilitating spinning. There are two main ways to card fibers: by hand and by machine. The objective of this experiment is to learn about carded yarn by machine, or a passage diagram of a carding machine.

Objectives:

- To remove the small trash and dust which have not been remove in blow room.

- Make the fibre parallel and straight.

- Elimination of the remaining impurities.

- To produce a thick untwisted rope of fibers called card sliver which is suitable for next processing.

Types of carding machine:

Based on operating principle and construction carding machines can be of the following types:

- Stationary flat carding machine.

- Revolving flat carding machine.

- Duo or tandem cards.

1. Stationary flat carding machine:

In the stationary flat carding machine the flat does not rotate and the flat covers one fourth of the cylinder that is why it was named as stationary flat carding machine.

2. Revolving flat carding machine:

In the revolving flat carding machines the revolves or rotate along with the cylinder.

3. Duo or tandem cards:

As the name implies, tandem cards consists of two individual cards joined together to make up a unit, in which the doffer of the first card feeds fiber material to the taker-in of the second card.

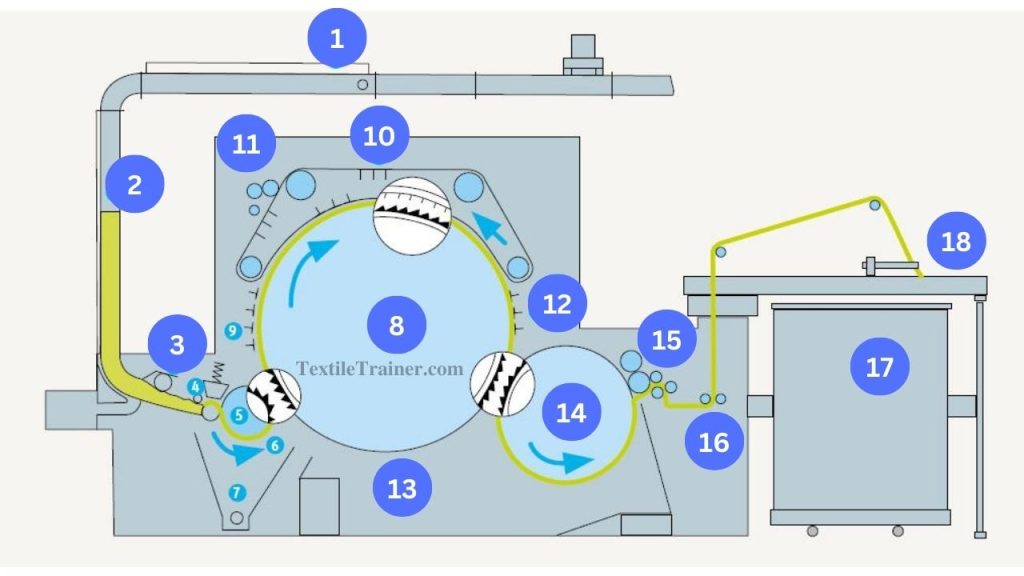

| 1= Pipe duct | 10= Flat |

| 2= Chute feed | 11= Cleaning unit |

| 3= Transport roller | 12= Fixed carding bars |

| 4= Feed arrangement | 13= Cylinder under case |

| 5= Taker-in | 14= Doffer |

| 6= Grid equipment | 15= Stripping device |

| 7= Suction ducts | 16= Calendar roller |

| 8= Main cylinder | 17= Sliver can |

| 9= Fixed carding bars | 18= Coiler |

Working Principle of Carding Machine:

A carding machine is used to process raw material after it exits the blow room. A pipe duct(1) supplies raw material into the feed chute(2) of the card. Approximately 500-900 ktex batts are formed in the chute. Material is transported from this batt to the feed arrangement (4) by a transport rollor (3). It consists of a feed roller and feeder plate that pushes the fiber sheet slowly into the taker-in(5) while maintaining optimal clamping force. A taker-in passes flocks over a grid equipment(6) and transfers them to the main cylinder(8) from the portion of the sheet projecting from the feed roller. The part of the sheet that project from the feed roller must be combed through and opened to flocks. By moving past mote knives, grids, carding segments, etc. Most of the impurities are lost in the process. The waste is carried away by suction ducts(7). In the actual carding process, flocks are carried along with the main cylinder, penetrate into the flats(10), and open up to individual fibers between these two devices.

A flat consists of 80-116 individual carding bars arranged in an endless pattern. A total of 30-46 flats are located in the carding position relative to the main cylinder; the rest are located on the return run. A cleaning unit(11) strips fibers, neps, and foreign matter during this return. The fixed carding bars (9) and (12) facilitate the operation of the card. The main cylinder’s underside is enclosed by grids or cover plates. The main cylinder carries along the loose, parallel fibers after the carding operation is completed. However, in this condition, the fibers cannot be transported as intermediate products. The doffer(14) is needed for this purpose as an additional cylinder. The doffer is able to combine the fibers into a web because its peripheral speed is substantially lower than the main cylinder’s. Stripping devices(15) remove the web from doffers. After the rollers (16) have compressed the sliver to some extent, the coiler (18) deposits it in cans (18). Working rollers, cylinders, and floats are provided with clothing that wears out during fiber processing, and they must be reground on a regular basis.

Technical Data:

| Raw materials | Cotton and man-made fibers up to 65 mm |

| Production | Up to 225 kg/h |

| Card sliver count | 4-20 ktex |

| Installed power | 23.5-29.8 kw |

| Delivery speed | Up to 330m/min |

| Cylinder speed | 600-900 rpm |

Conclusion:

The heart of a spinning mill is the carding machine.Quality of yarn depend on carding machine. From this experiment, we came to learn about different parts name and working principle of carding machine.

References

- Chowdhury, M. F. (2016). Manual of Short Staple Spinning . Dhaka: Granthanir Prokashoni.

- Klein, W. (2019). The Rieter Manual of Spinning. Switzerland: Rieter Machine Works Ltd.

Thanks a lot for the blog.Really thank you! Fantastic.

Thanks

Im thankful for the blog article.Much thanks again. Want more.

keep visit our site..

Enjoyed every bit of your article post.Much thanks again. Really Great.

thanks..

This is one awesome article. Great.

please support us….

Thanks-a-mundo for the blog article. Fantastic.

thanks too.

I appreciate, lead to I discovered just what I used to be taking a look for. You have ended my four day lengthy hunt! God Bless you man. Have a nice day. Bye

Thank you dear. Stay with us.

Really appreciate you sharing this blog article.Really looking forward to read more. Really Great.

keep visit our site.

Appreciate you sharing, great blog post.Thanks Again. Keep writing.

keep visit our site.

Hi, I do think this is an excellent blog. I stumbledupon it 😉 I am going to revisit once again since I book marked it. Money and freedom is the greatest way to change, may you be rich and continue to guide others.

Good post. I’m dealing with some of these issues aswell..

Keep visit our site….

I loved your blog article. Really Cool.

This blog was… how do I say it? Relevant!! Finally I have found something that helped me. Thank you!

Finnaly the knowledge I had been seeking. Many thanks for the aid.

It’s great that you are getting thoughts from this article as well as from our dialogue made at this place.

Stay with us

Very descriptive article, I liked that a lot. Will there bea part 2?

Thanks

There is noticeably a bundle to know about this. I assume you made sure good points in features also.

keep visit our site….

Oh my goodness! an amazing article dude. Thanks Nonetheless I’m experiencing issue with ur rss . Don’t know why Unable to subscribe to it. Is there anybody getting an identical rss downside? Anybody who is aware of kindly respond. Thnkx

Welcome. Stay with us

Thanks, I’ve recently been looking for info approximately this topic for ages and yours is the best I’ve came upon so far. But, what in regards to the bottom line? Are you certain concerning the source?

Thanks

Thanks in support of sharing such a pleasant opinion,post is fastidious, thats why i have read it completely

Hello my loved one! I want to say that this post is amazing, nice written and come with approximately all significant infos. I’d like to peer more posts like this .

Amazing issues here. I’m very satisfied to peer your article.Thanks a lot and I’m having a look ahead to touch you.Will you please drop me a e-mail?

Thanks

You made various fine points there. I did a searchon the matter and found most folks will consent with your blog.Feel free to surf to my blog post higher testosterone level

There is definately a lot to learn about this topic.

Thanks a lot

Fantastic article post.Much thanks again. Really Great.

Im thankful for the blog article. Want more.

Very neat article.Really thank you! Much obliged.

Thanks a lot for the article post.Thanks Again. Want more.

There’s certainly a great deal to learn about this subject. I like all the points you made.

please support us….

Great blog post.Really thank you! Great.

I really liked your blog article. Keep writing.

This is one awesome blog article.Really looking forward to read more. Really Great.

Im grateful for the blog.Much thanks again. Great.

thanks too….please support us……

I appreciate you sharing this blog post. Much obliged.

Great post.Really looking forward to read more. Want more.

Thank you ever so for you blog post.Thanks Again. Cool.

Thanks a lot for the blog article.Much thanks again. Want more.

Nicely put, Many thanks.steps to write a good essay what does dissertation mean thesis writing services

This is one awesome post.Really thank you!

Thanks too…

Great, thanks for sharing this article.Much thanks again. Fantastic.

Thank you for your article post.Much thanks again. Will read on…

Appreciate you sharing, great article.Really thank you! Keep writing.

Thanks for sharing, this is a fantastic blog.Much thanks again. Much obliged.

Im grateful for the blog.Really thank you! Great.

A big thank you for your article. Fantastic.

A big thank you for your blog. Awesome.

Awesome article post. Want more.

Thanks for the article. Will read on…

I appreciate you sharing this blog post.Really looking forward to read more. Really Cool.

Very good blog article.Thanks Again. Really Cool.

I appreciate you sharing this blog post.Really looking forward to read more. Awesome.

Very informative article.Really thank you! Really Cool.

Great article post.Thanks Again.

Major thankies for the blog article.Thanks Again. Cool.

Thank you for your article.Really looking forward to read more. Want more.

I think this is a real great article. Want more.

Thanks again for the article. Really Cool.

Awesome blog.Really thank you! Cool.

Very neat blog.Thanks Again. Cool.

Thanks in support of sharing such a fastidious opinion, post is good, thats why i have read it entirely

Wow, great article post.Really looking forward to read more. Keep writing.

Great blog post.

wow, awesome article post.Really looking forward to read more. Will read on…

Great information. Thanks for sharing.

Great article post.Thanks Again. Great.

Im obliged for the blog post.Thanks Again.

Thanks so much for the article post.Really thank you! Will read on…

Major thanks for the blog post.Really looking forward to read more. Will read on…

Wow, great blog post.Really thank you! Much obliged.

Fantastic blog.Much thanks again. Will read on…

wow, awesome blog post.Really thank you! Awesome.

Looking forward to reading more. Great article.Thanks Again. Will read on…

Appreciate you sharing, great blog post.Thanks Again. Cool.

I value the post. Will read on…

Im thankful for the blog article. Keep writing.

A big thank you for your article post. Great.

You ma’am have a way with words. Thank you very much!

Hey, thanks for the blog.Really looking forward to read more. Really Great.

I cannot thank you enough for the article post.Really looking forward to read more. Cool.

Say, you got a nice blog post. Keep writing.

There’s definately a lot to find out about this issue. I love all the points you have made.

Very informative blog article. Fantastic.

Thanks again for the blog post.Really thank you! Really Cool.

Really enjoyed this post.Really looking forward to read more. Want more.

Great article post.Really thank you! Will read on…

Hey, thanks for the blog post.Really thank you! Awesome.

wow, awesome blog.Really looking forward to read more. Awesome.

Hey, thanks for the blog post.Really thank you! Keep writing.

I am so grateful for your blog article.Much thanks again. Will read on…

Looking forward to reading more. Great article.Thanks Again. Great.

Thank you for your article post.Really thank you! Fantastic.

Really informative article.Thanks Again. Great.

Very good blog article.Much thanks again. Keep writing.

Thanks again for the blog article. Awesome.

I really liked your post.Much thanks again. Really Great.

Wow, great article.Really looking forward to read more. Great.

I appreciate you sharing this article. Cool.

I value the post. Really Cool.

Really informative blog post. Cool.

I really like and appreciate your article post. Awesome.

It is truly a great and helpful piece of information. I am satisfied thatyou just shared this useful info with us. Please stay usinformed like this. Thanks for sharing.

Thanks

Really enjoyed this blog article.Much thanks again. Will read on…

Thanks

I really like and appreciate your article.Much thanks again. Will read on…

Thanks for the article. Fantastic.

Major thanks for the blog post. Keep writing.

Thanks

Hi! I simply would like to offer you a big thumbs up for the excellent information you’ve got right here on this post. I am coming back to your blog for more soon.

It’s actually a nice and useful piece of information.I’m glad that you just shared this useful info with us. Please keep us informed likethis. Thank you for sharing.

Welcome

Really appreciate you sharing this blog. Fantastic.

Thank you ever so for you blog post. Awesome.

Really appreciate you sharing this article.Thanks Again. Want more.

Really informative post.Much thanks again. Cool.

Thank you ever so for you blog post.Really looking forward to read more. Awesome.

This is my first time visit at here and i am genuinely pleassant to read everthingat single place.

Thanks for the blog.Much thanks again. Much obliged.

I value the post.Really looking forward to read more. Great.

Awesome blog.Much thanks again. Awesome.

I really enjoy the article.Thanks Again. Much obliged.

Very good blog article.Thanks Again. Awesome.

I cannot thank you enough for the post.Much thanks again. Fantastic.

I really enjoy the blog post. Really Cool.

Wow, great blog post.Really looking forward to read more. Really Great.

I think this is a real great article.Thanks Again.

Enjoyed every bit of your blog article.Really thank you! Really Great.

Hey, thanks for the article post. Great.

Kerassentials are natural skin care products with ingredients such as vitamins and plants that help support good health and prevent the appearance of aging skin. They’re also 100% natural and safe to use. The manufacturer states that the product has no negative side effects and is safe to take on a daily basis.

Hey, thanks for the blog article.Thanks Again. Awesome.

Awesome article post.Really thank you! Want more.

Im grateful for the blog post.Really looking forward to read more.

Very good blog article.Much thanks again. Really Great.

A big thank you for your article.Much thanks again. Fantastic.

Really informative post.Really thank you!

I really enjoy the post.Really thank you! Will read on…

Fantastic article post.Really looking forward to read more. Keep writing.

Wow, great blog article.Really thank you! Great.

Thanks for sharing, this is a fantastic blog post.Really thank you! Cool.