1. What is Spinning?

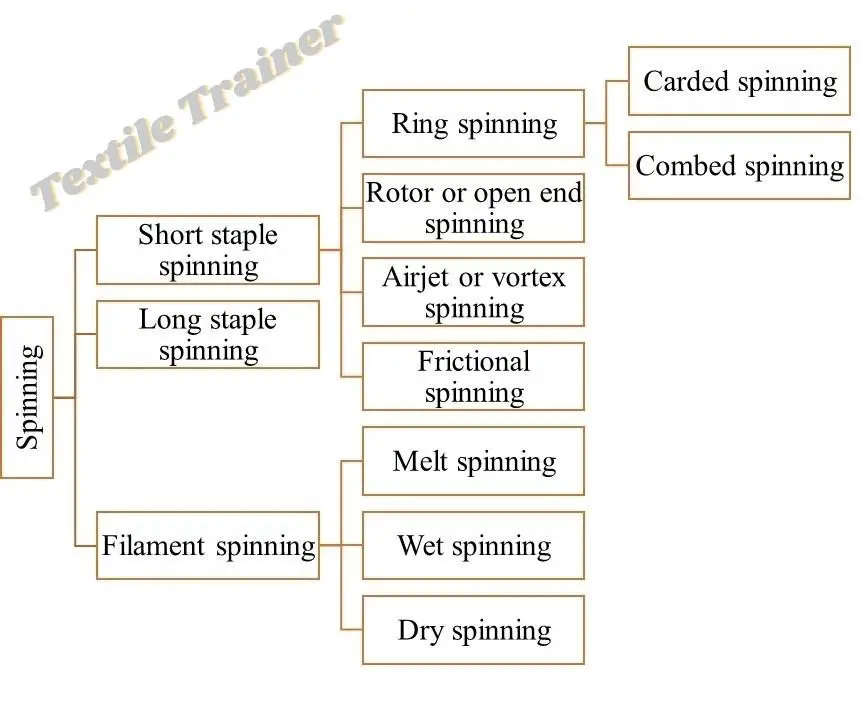

Spinning is the final stage of yarn manufacturing. The spinning method that utilizes the roller drafting for fiber mass attenuation and the combination of freely circulating traveler around a ring to insert twist for consolidation, and the produced yarn is wound onto a bobbin for suitable package formation is called spinning. In other words, the process used to convert fiber and filament into yarns for weaving or knitting into fabrics. Spinning is an essential part of the Textile Industry. There are many kinds of spinning methods. There are classified as follow:

2. Classification of Spinning:

In this article, I will brief classification of spinning.

2.1 Short Staple Spinning:

This process is much more complicated and requires several

stages need to be done before staple yarns can be produced. Making yarn by twisting all those fibers between two 1/2 to 2 1/2 inches in length is called short-staple spinning. There are four kinds of short-staple spinning as follow:

- Ring staple spinning.

- Rotor or open end spinning.

- Air-jet or vortex spinning.

- Frictional spinning.

2.1.1 Ring Staple Spinning:

Ring staple spinning is conventional spinning. Ring spinning remains the standard by which spun yarns are judged. Even with continuous spinning, higher speeds, and automation, spinning remains a long and expensive process. Ring-spun yarns are finer, smoother, have better quality, are more uniform, and create fewer problems in fabrication. Ring spinning is more versatile than alternate spinning systems. This system processes many fine-spun yarns.

2.1.2 Rotor or Open End Spinning

Rotor or open-end spinning is a relatively recent development in spun yarn production. In the rotor spinning process, the fibrous material is highly drafted or opened, ideally to the individual fiber state, creating a break in the continuum of the fiber mass. The individual fibers are subsequently collected onto the open end of a yarn that is rotated by a device to twist the fibers into the yarn structure to form a continuous yarn length, and the length of yarn spun is then wound to create a package.

2.1.3 Air Jet or Vortex Spinning

Air-jet spinning yarn with the aid of an air stream was developed in Japan. Commercially Air-jet spinning was introduced in 1981. In air-jet spinning, a narrow sliver is fed into a machine with two nozzles facing opposite directions. Each nozzle blows air against the sliver forcing the outermost fibers to wrap around the sliver, which produces a yarn. Air-jet yarns are less elastic, weaker, and rougher than either ring or rotor-spun yarns.

2.1.4 Frictional Spinning

Dr. Ernst Fehrer developed friction spinning in 1971. Friction spinning is an open end or a break turning in which the yarn formation takes place with the aid of frictional forces of rotating rollers in the spinning zone. The yarn properties of friction spinning more closely resemble ring spun rather than open-end rotor spun yarn, while lower production costs over both are emphasized. Weaving performance compares favorably with that of conventional yarns. Friction spinning is used jeans, home furnishings such as upholstery, industrial products such as cords, and leisure goods such as camping articles.

2.2 Long Staple Spinning

Making yarn by twisting all those fibers’ lengths greater than 2 1/2 inches is called long staple spinning. The long staple spinning process is used for jute, wool, and flax fiber.

2.3 Filament Spinning

For producing synthetic or man-made fibers, the polymers must be unfolded and extended uni-directionally to extremely large dimensions to get a high length-to-diameter ratio and high orientation. The filament spinning method is used for making man-made fiber. The filament is an untwisted rope of thousands of filament fibers. This rope combines the fibers from many spinnerets, each of which may have thousands of holes. The two is crimped and converted into staple by cutting or breaking to the desired length. Filament spinning are classified as follow:

- a)Melt spinning.

- b)Wet spinning.

- c)Dry spinning.

2.3.1 Melt Spinning

In melt spinning, polymers are melted in an autoclave. Then pumped through a spinneret into an air chamber. The extruded streams cool, solidify into continuous filaments and are drawn out of the chamber. Fiber is spun out into the air. Then fiber solidifies on cooling. Monofilament and multi-filament yarns of various diameters can be produced as is done with the other extruded filaments. Fibers like Polyester, Nylon, Olefin, Polypropylene, Saran, etc., can be spun by melt spinning.

2.3.2 Wet Spinning

The first commercially successful method for manufacturing man-made fiber was the wet spinning of cellulosic fiber. This method is still used today. Essentially, the process involves using an appropriate liquid solution pumped through a small nozzle called a spinneret into a chemical bath that coagulates the extruded solution of endless strands of filaments. These continuous coagulated fibers are drawn out of the bath, purified by washing, dried, and then wound onto spools. Wet spinning spins fibers like Acrylic, Rayon, Aramid, and spandex.

2.3.3 Dry Spinning

The dry spinning method is another method for the manufacture of man-made fibers. In this method, polymer cheep is dissolved by the solvent. Then polymer liquid is pumped through a spinneret into a hot air chamber. The air reacts with the extruded streams causing them to solidify. Fibers like Acetate, Tri-acetate, Acrylic, Modacrylic, Spandex, and Vinyan fibers are spun by wet spinning methods.

References

- Belal, P. D. (2009). Understanding Textiles for a Merchandiser . Dhaka: L.B graphics and Printing.

- Chowdhury, M. F. (2016). Manual of Short Staple Spinning . Dhaka: Granthanir Prokashoni.

- Corbman, B. P. (1983). Textiles Fiber to Fabric. New York: Mc Graw Hill.

- Hossain, M. S. (2014). Introduction to Textile Engineering. Dhaka: Books Fair Publications.

- Kadolph, S. J. (2009). Textiles. New Delhi: Dorling Kindersley.

This really answered my problem, thank you!

Great website! I am loving it!! Will be back later to read some more. I am taking your feeds also.

Thank you ever so for you article post.Really looking forward to read more. Really Cool.

Very informative post.Thanks Again. Great.