3D Knitting Technology: An Innovation in Modern Textile

Introduction

3D knitting technology is a modern technology in the textile industry. 3D knitting technology creates three-dimensional shapes of garments directly on the knitting machine. In the traditional knitting process, flat fabrics make initially. Then the fabric is cut and sewn together. But the technology of 3D knitting produces ready-to-use shapes in one piece. Hence, this knitting technology reduces waste, saves time, as well as allows designers to make complex and innovative garment designs simply. However, this article is about 3D knitting technology, types of 3D knitting, the mechanism, and applications. Besides, this article will describe the advantages and limitations of 3D knitting.

What is 3D Knitting Technology?

3D knitting is a modern knitting technology as well as a modern textile manufacturing method. In 3D knitting technology, one piece of a garment is created directly in a knitting machine, where no need for cutting or sewing. In simple words, 3D knitting makes ready-shaped fabrics (shoe uppers, cushions, braces, automotive, etc.) directly during knitting. It uses computer-controlled machines. This machine can manage each needle individually to form curves, thickness, and shapes in one continuous process.

It is an innovative textile manufacturing process. It is also a sustainable and eco-friendly textile manufacturing process. Because 3D knitting technology uses less energy, less chemicals, less water, as well as reduces waste and production cost for making one piece of garment. Thus, 3D knitting technology is a sustainable and eco-friendly textile process.

Types of 3D Knitting Technology

People of the world always search for innovative textile to reduce pollution of the world. The textile industry also always searches for new eco-friendly textile products. However, 3D knitting is such a new, innovative textile process. Mainly, 3D knitting can be classified into two ways.

1. Structural-based classification

- Multiaxial 3D knitting: Multiaxial 3D knitting fabrics made with yarns running in multiple directions. It is used in composites.

- Spatial knitting: Spatial 3D knitting is done on a flat-bed or circular CAD/CAM knitting machine. It creates fabric with complex shapes similar to the final product. The shape is formed by increasing or decreasing the number of working needles, allowing for the production of 3D structures such as tubes, spheres, or cones.

- Sandwich knitting: Sandwich knitted fabrics are two separate knitted fabric layers. Yarns or knitted structures connect two knitted fabric layers. Fabric thickness depends on the number of fabric layers. The connecting layers can be single or double. Single layers use perpendicular or angled yarns. Double layers are knitted separately on both beds. These fabrics can be shaped using interior and exterior moulds, where resins and polyurethane foam are applied to create and fix the final 3D form.

2. Machine-based classification

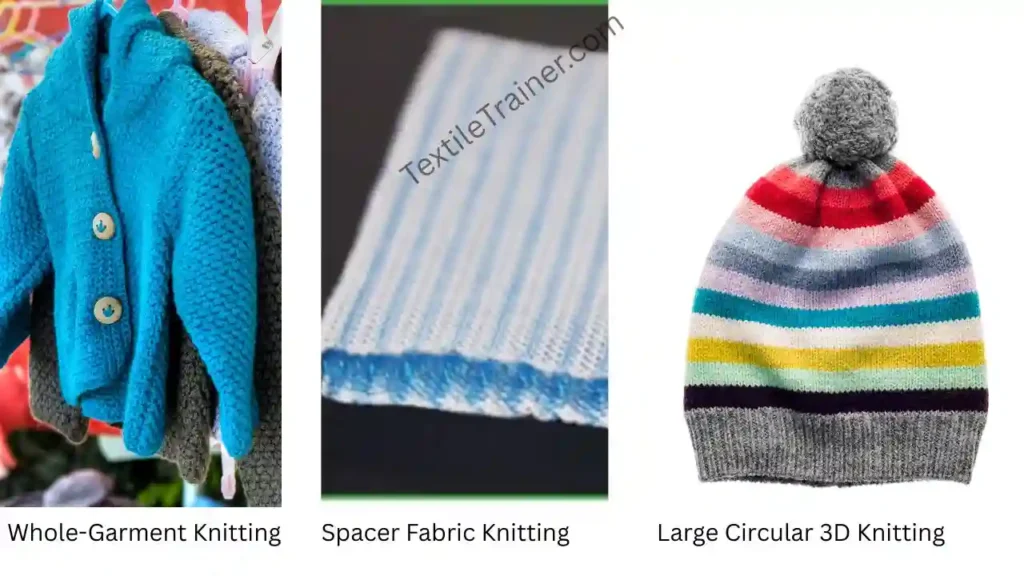

- Whole garment knitting: Whole garment knitting is a process where the entire garment is made in one piece without any sewing or linking. Example: sweaters, leggings, and sportswear.

- Spacer fabric knitting: Spacer fabric knitting produces three-dimensional sandwich structures. The fabric has two outer layers connected by vertical yarns or pile threads. Example: shoe uppers, car seats, mattresses.

- Large circular 3D knitting: Large circular 3D knitting is a new and high-speed technology. It uses jacquard circular knitting machines that work continuously to create 3D shapes. The process is based on a “sewing-like pattern” made with flats and stitches. Some needles stop knitting while others continue, which reduces the surface area and forms curves or domes. Example: Bra cups, protective pads, and shaped panels.

Mechanism of 3D knitting

3D knitting is an advanced textile technology. This advanced textile technology helps reduce fabric waste, improves accuracy. The mechanism of 3D knitting on large circular knitting machines works by forming 3D shapes. A special computer program is added in the knitting machine. This computer controls the individual needle of the knitting machine. In easy words, each needle can be knitted or stopped separately by using a computer control system. This system makes it possible to form different areas of stretch, tightness, and shape within the same fabric.

The main principle of 3D knitting is based on a special sewing-like pattern. It is similar to how darts are used in the sewing of garments. This pattern reduces the surface area of the fabric in certain zones. It is allowing the material to naturally form curves and a 3D structure. The knitting design is created with a mix of floats and stitches. In the area that needs to be reduced, some needles remain inactive. As a result, the yarn floats over them and holds the fabric in place. In this time, the active needles continue knitting loops on the backside.

This difference between active and inactive needles creates variation in fabric tension. Hence, one side of the fabric becomes tighter, and the other side of the fabric remains looser. As a result, a three-dimensional shape is formed on the fabric. Throughout the process, the machine runs continuously smoothly and maintains a high production speed.

Application of 3D knitting

3D knitting has wide use in both fashion and technical textiles. Some application is given below:

- 3D knitted fabric is used for sportswear and fashion purposes. Example: whole garment T-shirts, leggings, sports bras, and shoes.

- It is also used in automotive and furniture. Example: car seat, cushions, and upholstery.

- It is used as protective clothing and aerospace materials

- 3D knitting is widely used in sports and casual shoes. Example: Nike Flyknit, Adidas Perimeknit shoes.

- This fabric uses in a medical textile. Example: orthopedic supports, medical braces, and bandages

Advantages of 3D knitting

- In 3D knitting technology, the garment is ready in one piece. Hence, no sewing is required.

- In this modern textile technology, only yarn is used. Thus, this innovative textile process reduces fabric waste.

- 3D knitted fabric is comfortable to wear owing to the seamless and stretchable designs.

- No need to cuting section and sewing section.

- This advanced textile technology is a sustainable and eco-friendly textile process. Because this innovative textile process uses less water, less chemicals, less energy and reduces whole cost of garment production.

Disadvantages of 3D Knitting

Though 3D knitting technology has lots of advantages but it has some demerits.

- 3D knitting has limited shaping flexibility compared to flat knitting.

- This technology needs skilled manpower for machine setup and programming.

Conclusion

3D knitting technology combines creativity, efficiency, and sustainability with the help of digital pattern design and computer-controlled machines. This textile technology opens the door to future careers in smart textiles, innovative textiles, and eco-friendly textile products. This process has some problems still now. But, researchers works and try to establish a key part of the next generation textile manufacturing- combining design freedom with eco-friendly textile products.

Reference

- K. Simonis, Y. S. Gloy, and T. Gries, “3D knitting using large circular knitting machines,” IOP Conf. Ser. Mater. Sci. Eng., vol. 254, no. 9, 2017, doi: 10.1088/1757-899X/254/9/092004.

- C. Peiner, H. Löcken, L. Reinsch, and T. Gries, “3D Knitted Preforms Using Large Circular Weft Knitting Machines,” Appl. Compos. Mater., vol. 29, no. 1, pp. 273–288, 2022, doi: 10.1007/s10443-021-09956-1.

- Y. Igarashi, T. Igarashi, and H. Suzuki, “Knitting a 3D model,” Comput. Graph. Forum, vol. 27, no. 7, pp. 1737–1743, 2008, doi: 10.1111/j.1467-8659.2008.01318.x.