Eco-Friendly Denim Re-Dyeing Process with Charcoal

Introduction

Sustainable textile processing is becoming more important. Because, fashion industry faces pressure to decrease textile chemicals, water pollution, and waste. Denim is one of the most widely used in worldwide. Researchers are searching for an eco-friendly denim re-dyeing process. This article will discuss the denim re-dyeing process using charcoal. This process is a sustainable dyeing process. Charcoal is a kind of fuel. It is used for a blacksmith’s fire and other uses that demand high heat. Historically, charcoal has been utilized as a source of black pigment.

Why Look for Alternatives to Conventional Denim Dyeing?

Traditional denim fabric is dyed using sulfur dye, indigo dye, and pigments. But, these dyestuff create some problems:

- In the case of sulfur dye, strong reducing agents are used. This reducing agent contains toxic compounds, which is risks for the environment.

- Additionally, indigo requires multiple dips. Hence, it produces a large amount of colored effluent.

- On the other hand, pigment dyes require binders and crosslinkers. This often leads to stiff fabric.

Because of these limitations, textile scholars are exploring alternative processes. Hence, this article will be brief an eco-friendly denim re-dyeing process using charcoal.

Typical Recipe for Denim Re-dyeing

| S/N | Chemical | Amount (gm/L) |

| 1. | Binder | 17 g/L |

| 2. | Fixer | 10 g/L |

| 3. | Charcoal | 60 g/L |

| 4. | Fabric | 10 g |

| 5. | Temperature | 700 C |

| 6. | Time | 40 |

| 7. | M: L | 1:30 |

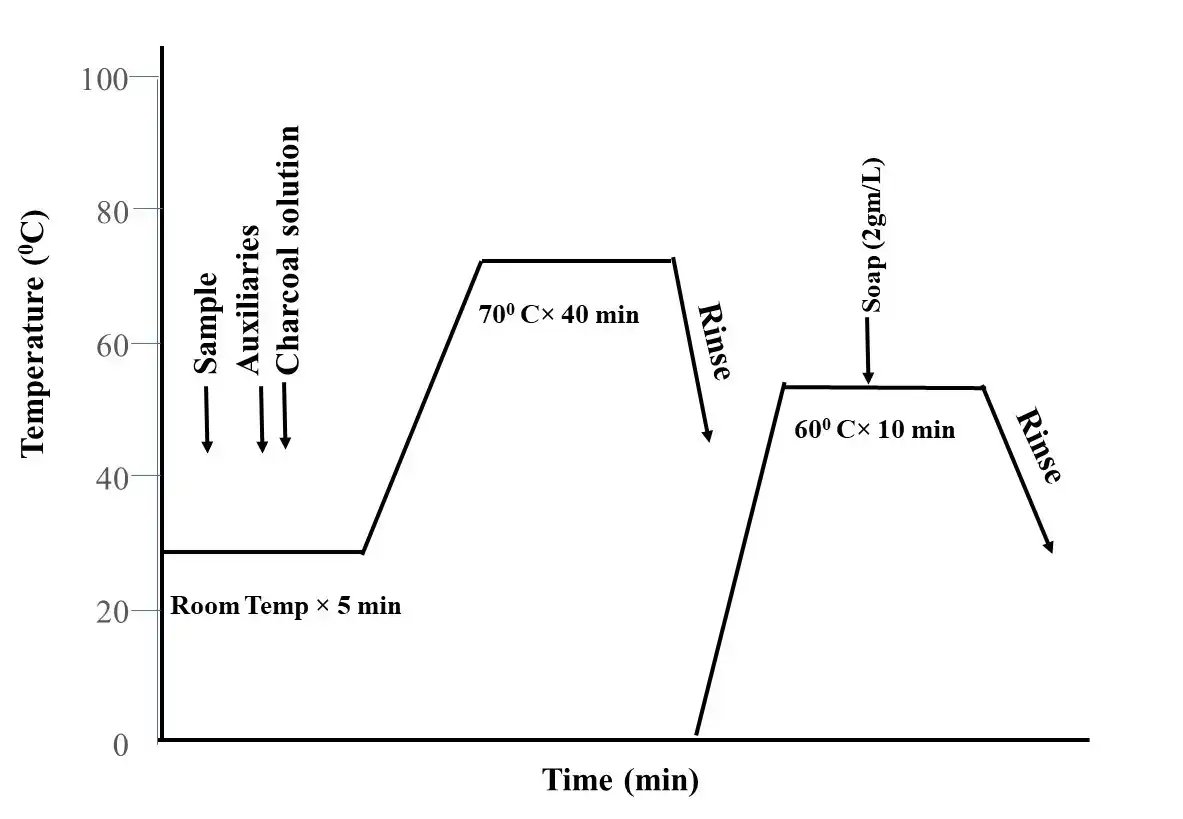

Denim Dyeing Curve

Denim Re-dying Process

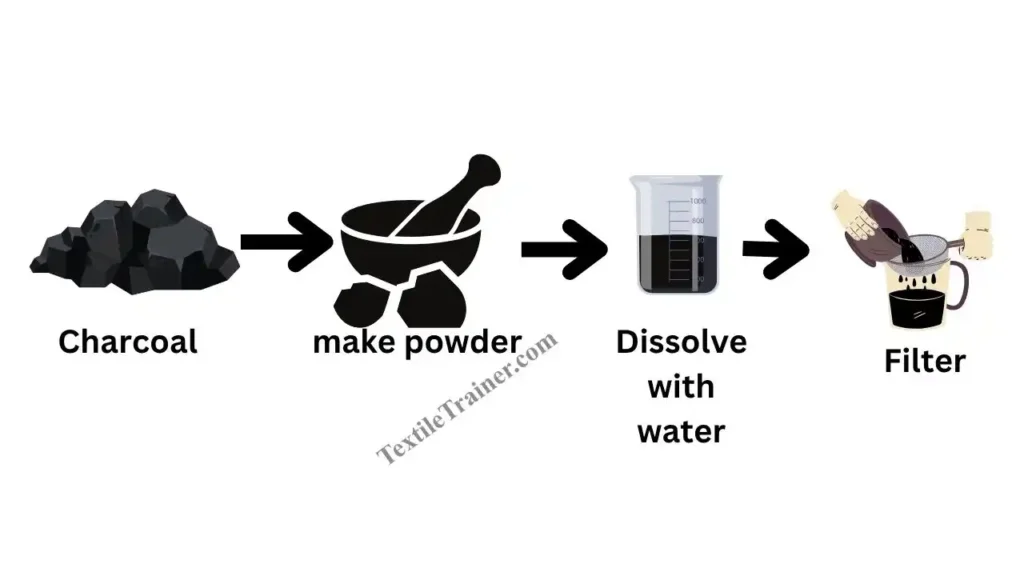

- Initially, charcoal was brought from local market. Now, charcoal is made in powder form by using a mortar. Next step, charcoal powder is mixed in water according to the recipe. Now, filtered the solution to remove residual charcoal.

- All required chemicals are measured accurately according to the charcoal dyeing recipe.

- Now, all chemicals and charcoal solutions are transferred into the dyeing pot. Also, add the fabric to the dyeing pot.

- Load the dyeing pot into the dyeing machine.

- Subsequently, Raise the temperature of the dyeing machine to 70 °C and maintain it for 40 minutes.

- After the dyeing time is over, unload the dyeing pot and rinse the denim sample.

- Then, sample is treated with soap (2 g/L) at 60 °C for 10 minutes to remove unfixed charcoal from the fabric surface.

- Finally, dry the sample in an oven at 70 °C.

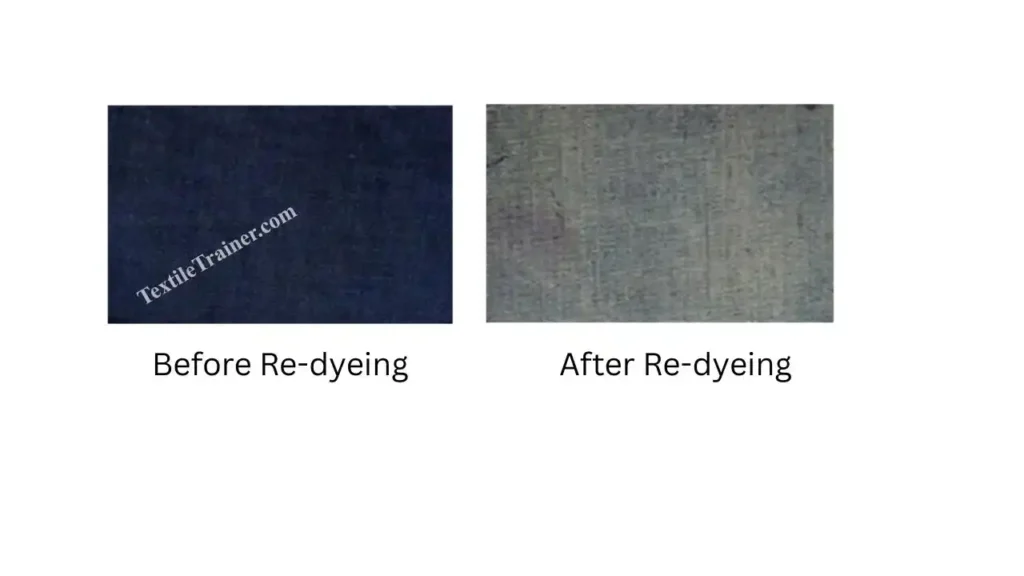

Denim Re-dyed sample

Color fastness Properties

| Color fastness to water | ||||||

| Change in color | Staining in color | |||||

| Acetate | Cotton | Poly amide | Polyester | Acrylic | Wool | |

| 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 |

| Colorfastness to wash | ||||||

| Change in color | Staining in color | |||||

| Acetate | Cotton | Poly amide | Polyester | Acrylic | Wool | |

| 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 |

| Color fastness to perspiration (Alkaline) | ||||||

| Change in color | Staining in color | |||||

| Acetate | Cotton | Poly amide | Polyester | Acrylic | Wool | |

| 4-5 | 4 | 4-5 | 4-5 | 4-5 | 3-4 | 4 |

| Color fastness to perspiration (acid) | ||||||

| Change in color | Staining in color | |||||

| Acetate | Cotton | Poly amide | Polyester | Acrylic | Wool | |

| 4-5 | 4 | 4-5 | 4-5 | 3-4 | 4-5 | 4 |

| Color fastness to rubbing | ||||||

| Dry | Wet | |||||

| 4 | 3 | |||||

Almost all color fastness properties show good to excellent aspects, color fastness to rubbing.

You may Read: Colorfastness to Rubbing Easy Testing Procedure

Limitation

- The rubbing fastness property needs to improve.

- The recipe relies on binders and fixers. Hence, this denim re-dyeing process is not a 100% sustainable dyeing process.

- Sade’s range is limited.

Conclusion

This article shows that charcoal denim dyeing can be an effective, eco-friendly colorant for denim re-dyeing. It also shows good to excellent colorfastness properties. But, rubbing fastness properties is not good. Final thoughts are that it is not a complete alternative to synthetic dye.

FAQs on Denim Re-dyeing with Charcoal

- How is charcoal better for the environment?

- Charcoal is a biodegradable, non-toxic compound. On the other hand, denim re-dyeing with charcoal needs less water and energy compared to conventional denim dyeing processes. It also reduces chemical pollution in wastewater. Hence, charcoal is better for the environment.

- Can charcoal re-dyeing match the color intensity of traditional dyes?

- No, charcoal re-dyeing doesn’t match the color intensity of traditional dyes. It has some limitations regarding shade limitation and rubbing fastness properties.

- Does charcoal re-dyeing effect denim durability?

- No. because, this eco-friendly denim re-dyeing process is gentle on fabric fibers.

- Can this method be applied at an industrial scale?

- No, because of some limitations, this method can not be applied at an industrial scale. On the other hand, thought, it is sustainable dyeing process, but shade’s range is limited.

- How is the fastness of charcoal dyed denim?

- Charcoal dyed denim shows good to excellent color fastness properties, without rubbing fastness property.

You may read: Jute Scouring Process: A Complete Easy Guide for Beginner

Reference

- Mahir, S. Q., & Manufacturing, A. (n.d.). AN ECO-FRIENDLY APPROACH TO RE-DYEING COTTON DENIM FABRIC WITH CHARCOAL : A COMPREHENSIVE STUDY. 1–12.

- Dakuri, A. (2013). MNF Technology of industrial denim washing : review. International Journal of Industrial Engineering & Technology, 3(4), 25–34.

- Fang, K., Wang, C., Zhang, X., & Xu, Y. (2005). Dyeing of cationised cotton using nanoscale pigment dispersions. Coloration Technology, 121(6), 325–328. https://doi.org/10.1111/j.1478-4408.2005.tb00377.x

- Booth, J. (2008). Principles of Textile Testing. New Delhi: BS Publishers & Distributors.