Introduction:

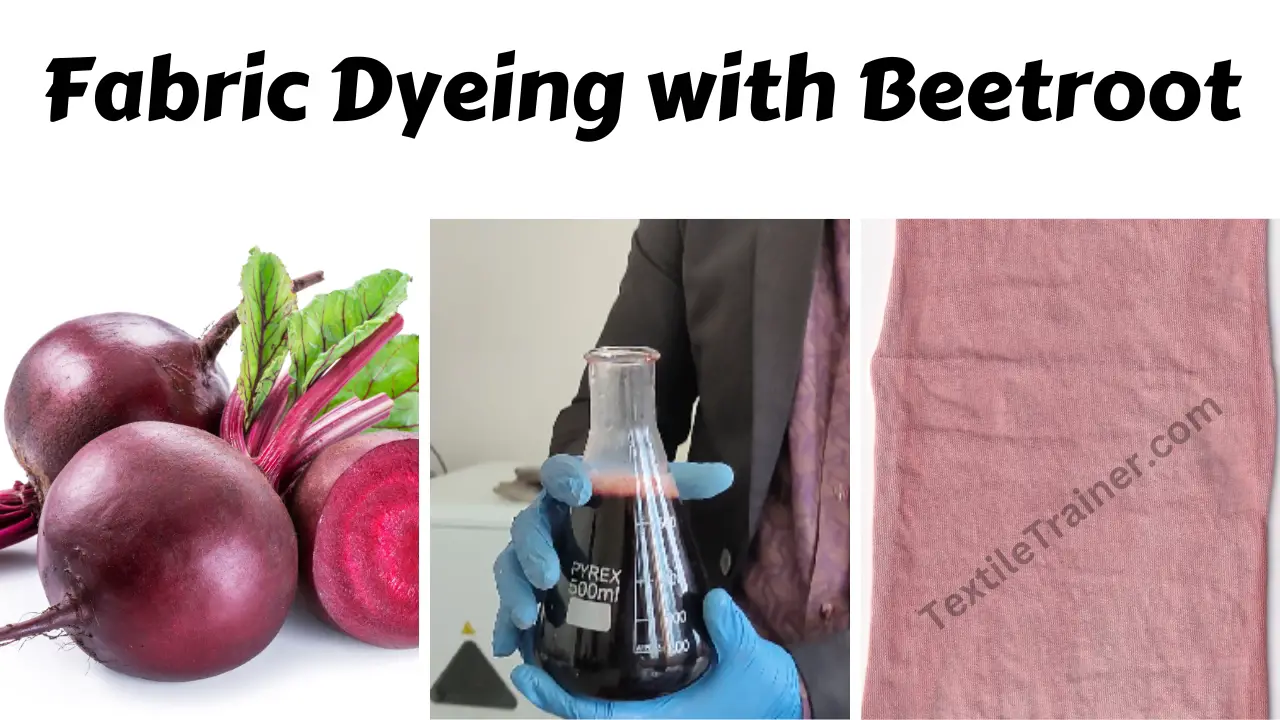

In this article, I will present to you cotton fabric dyeing with beetroot. A natural dye can be obtained from plants, invertebrates, insects, fungi or minerals. Most natural dyes are vegetable dyes, which are derived from various parts of plants such as roots, stems, seeds, barks, leaves, and wood. Additionally, there are several biological sources, including fungi, snails, insects, etc. Prior to chemical dyeing, natural dyes were the main sources of textile dyes. However, there are some elements other than plants that produce some expensive colors, such as sea snails and cochineal insects. In addition, we know that natural dyes have been used extensively for dyeing textile materials since ancient times, until synthetic dyes were developed and commercialized. Natural dyes can be obtained from a variety of sources. One of those sources is plants. We will see you how to dye cotton fabric with natural dyes derived from beetroot in this article.

History of Natural Dyes: From Ancient to Modern World

- Binomial Name: Beta vulgaris

- Family: Amaranthaceae

- Genus: Beta

- Part used: Root

- Extract color: Red to pink

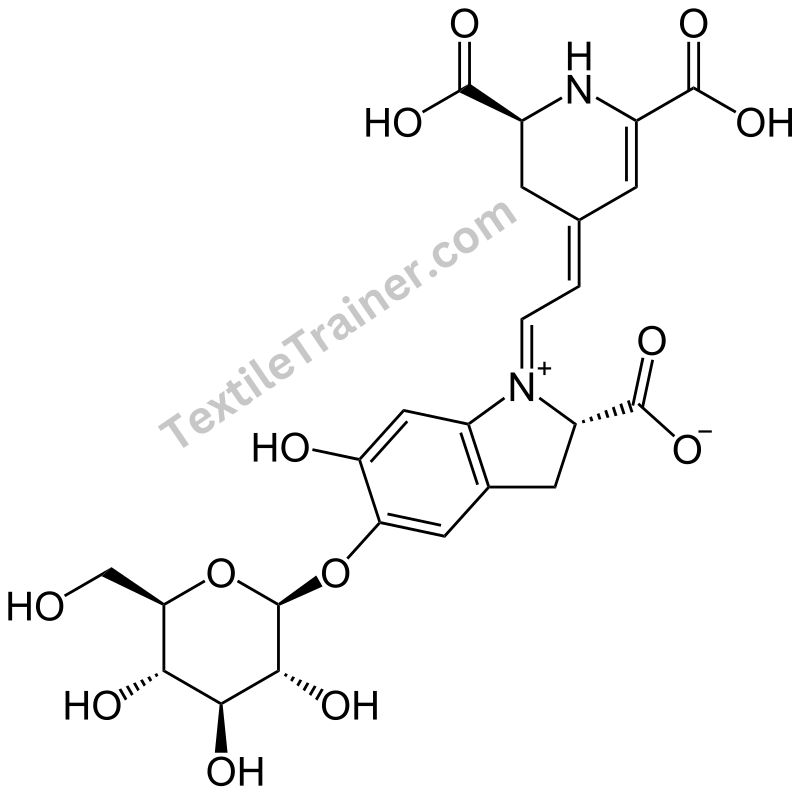

Beetroot (Beta vulgaris L.) is the most common root in the class of beets, and its bulk colors vary from yellow to red. The beetroot plant is a fruit that is easily available in nature and has many health benefits. It can also be used to dye textiles like fiber, yarn and fabrics. It contains the colour-bearing compound “Betanin”, which imparts a red or pinkish red hue to textiles. Following is the chemical structure of Betanin.

Latest Classification of Natural Dyes in 3 Way

Fabric Dyeing with Beetroot:

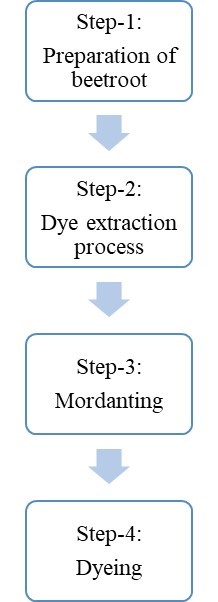

Below is a flow chart that outlines of fabric dyeing with beetroot.

Step-1: Preparation of Beetroot

- We collected fresh beetroot from local market.

- After that, wash the beetroot by using fresh water in order to remove soil and any other debris.

- After cleaning the beetroot, cut it into small pieces like chips or chunks.

- Now, arrange the beetroot pieces on trays or plates and dry them to the sun.

- Check the drying process continuously until all moisture has been removed. When remove all moisture from the beetroot then it become crispy.

- Using a blender, blend the crispy beetroot pieces into fine powder.

- Now , we get fine beetroot power.

4 Authentic Sources of Natural Dyes is Describe Easy Way

Step-2: Dye Extraction Process

- To prepare the solution, we took 1 liter water in a pot.

- mix 80 grams of beetroot powder with 1 liter water.

- The mixture heated to approximately 50 degrees Celsius and kept there for 20 minutes.

- After 20 min, remove the heat source and allow it to cool naturally for 10 minutes.

- Once the solution has cooled, again heat it to the previously mentioned temperature and time.

- After 20 min, Cool the solution again until it reaches room temperature.

- After cooling, filter the solution to remove any residual waste or solids.

- Finally, we got beetroot dye solution.

Step-3: Mordanting

There is no affinity between natural dyes and fabrics. Mordants are used to increase the affinity of dye to fabrics. Mordants do not only give the dye an affinity to fabric, it can also produce different colors and improve dye fastness. Mordants can be found both naturally and synthetically. For this article, we used Aloe vera as a natural mordant and potash alum [K2SO4.Al2(SO4)3.24H2O] , FeSO4 as a synthetic mordant.

The mordanting process will be carried out according to the following parameters:

- Aloe vera: 50% , (weight of fabric.

- Potash alum: 3%, weight of fabric.

- FeSO4: 3%, weight of fabric.

- Temperature: 600 C

- Time: 45 min

- Fabric weight: 5 gm.

- M:L: 1:20

We will dye total 4 sample by using beetroot extract dyes. One sample we will dye without mordant and other three sample with mordant. Three sample we will done mordanting process according the mention above parameter.

- S1: Without mordant.

- S2: Aloe vera treated.

- S3: Ferrous sulfate treated.

- S4: Potash Alum

Step-4: Dyeing

- For the dyeing process, we prepared four dyeing pots.

- One dyeing pot for without mordant treated sample. Other three pot for mordant treated sample.

- Fill each dyeing pot with 100 ml of the beetroot extracted dyes.

- In the dyeing machine, load the dyeing pots.

- Set dyeing temperature 400 C for 45 min.

- After dyeing is done, unload the dyeing pots from the machine.

- Now, rinse the sample with water to remove unfixed dyes.

- Dried the dyed sample at 500 C temperature.

Result:

According to the visual assessment potash alum treated sample show better shade, then ferrous sulfate treated sample, then aloe vera treated sample and then without mordant treated sample.

Potash alum > Ferrous sulfate > Aloe vera > without mordant

Reference:

- Hudu, A., Saeed, S. A., & Gumel, S. M. (2020). Studies on the Dyeing Properties of Cotton and Antimicrobial Activity of Natural Colourant Extracted from Beta vulgaris (Beetroot). Earthline Journal of Chemical Sciences, May 2020, 53–66. https://doi.org/10.34198/ejcs.4120.5366

- Sarker, P., Hosne Asif, A. K. M. A., Rahman, M., Islam, M. M., & Rahman, K. H. (2020). Green Dyeing of Silk Fabric with Turmeric Powder Using Tamarind Seed Coat as Mordant. Journal of Materials Science and Chemical Engineering, 08(02), 65–80. https://doi.org/10.4236/msce.2020.82007

- Parekh, S. G., & Solanki, H. A. (2023). NATURAL TEXTILE DYEING : a REVIEW. July.

- Salauddin Sk, M., Mia, R., Haque, M. A., & Shamim, A. M. (2021). Review on Extraction and Application of Natural Dyes. Textile & Leather Review, 6257(June), 1–16. https://doi.org/10.31881/TLR.2021.09