Introduction:

Colorfastness to rubbing means a change in color in rubbed textile material. A crockmeter test cloth is used to determine whether color can be transferred from the surface of a colored textile to a specific crockmeter test cloth for rubbing in dry and wet conditions. Color is provided by pigments that are fixed to the exterior of the fibers, so rubbing fastness is of great importance to prints. Crocking is a simple way to determine fabric fastness to rubbing by examining the surface of the fabric, which is the first part of the fabric that is attacked when it is rubbed or abraded. Some rub fastness tests require more rubbing cycles than the standard 10 used in the crocking test to break down a faulty pigment binder system. It has been developed test methods and testing equipment that have an increased abrasive effect on fabric surfaces. Among them are oscillating drums, wire mesh, and emery abrasion testers. These testers are used for textiles that require high abrasion resistance, such as military fabrics, because they abrade the surface more than the crock meter. Rubbing a surface often results in color changes or frosting after rub fastness testing. In prints, frosting occurs when pigment rubs away from the fabric surface, exposing the natural fiber color beneath. It is also known as fibrillation, since individual fibers poke through the print’s surface. When the print loses its depth of shade, frosting is easily detected.

Objectives:

- To know about fastness properties of fabric.

- Come to learn testing procedure of rubbing fastness dry and wet condition.

- To know how to measure rubbing fast.

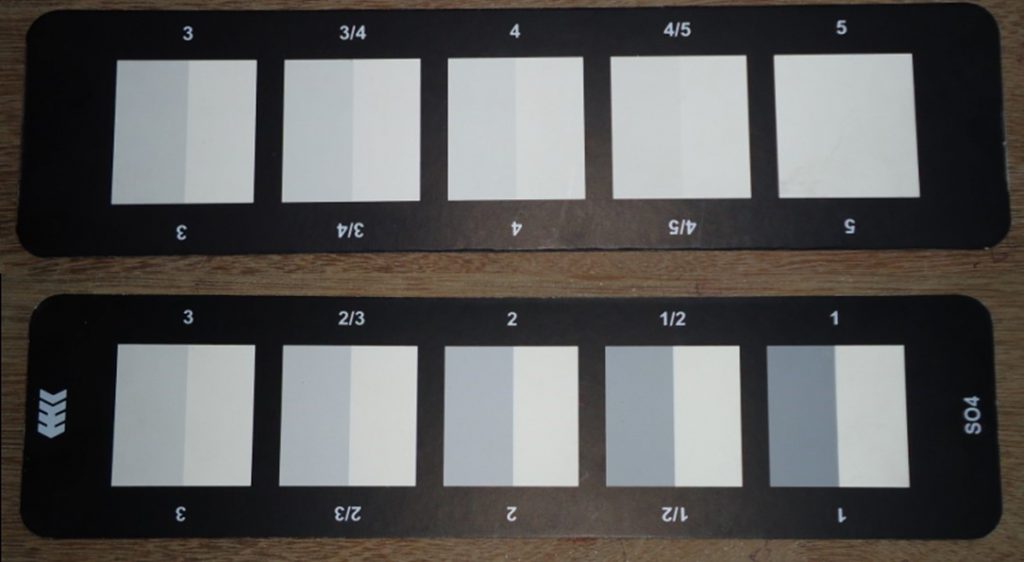

Degree of Staining Grey Scale:

Staining is measured using a different gray scale. Rating 5 shows two identical white samples, while rating 1 shows a white and a gray sample. In the other numbers you can see the geometrical steps of contrast between white and a series of greys. An unstained, undyed cloth is compared to one that has been treated during the staining test, and the staining is numerically assessed.

| Fastness Grade | Color staining | Fastness |

| Grade-5 | No staining | Excellent |

| Grade-4 | Very slight staining | Good |

| Grade-3 | Moderate staining | Fair |

| Grade-2 | Significant staining | Poor |

| Grade-1 | Deep staining | Very poor |

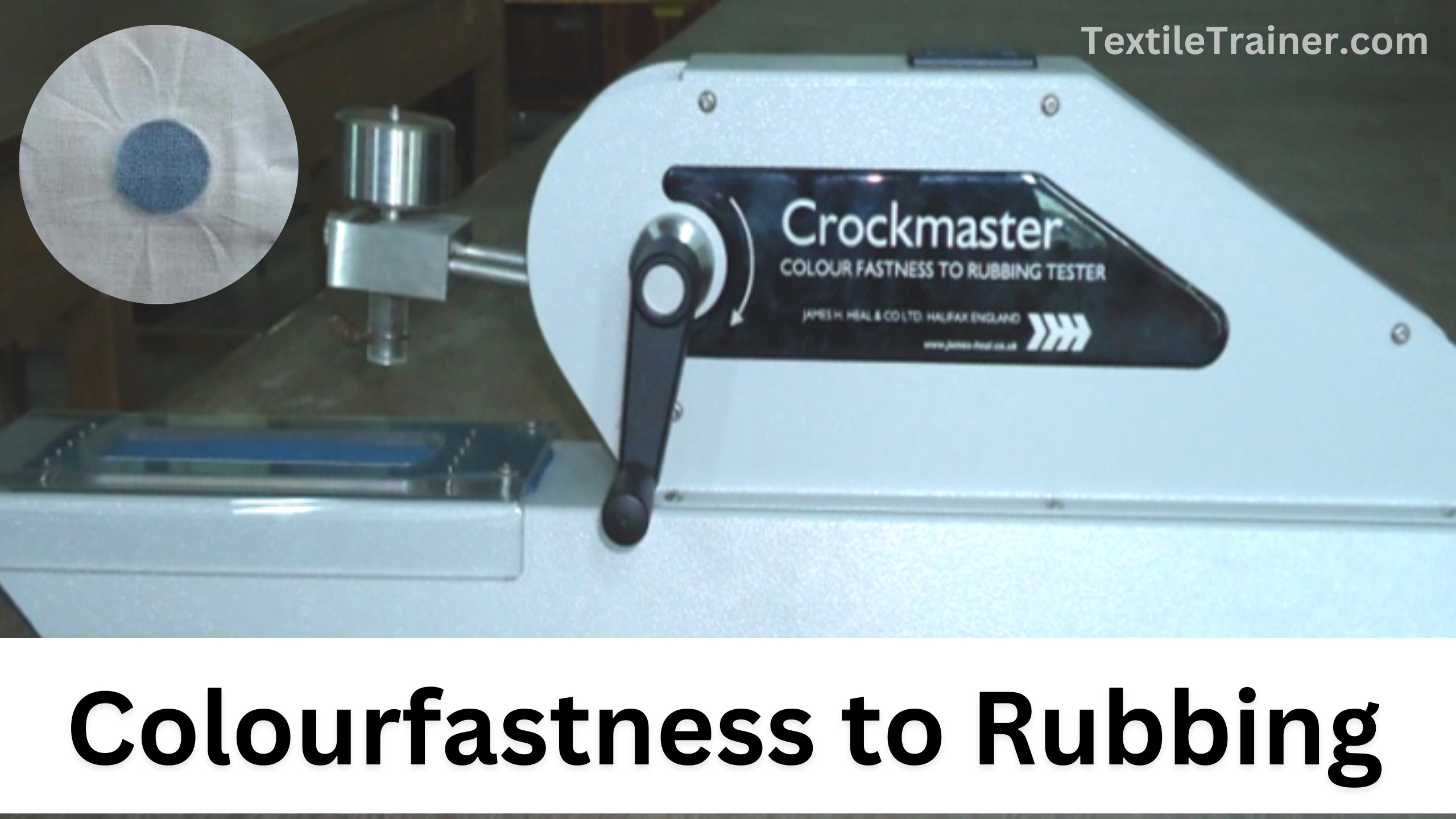

Apparatus:

- Crockmeter.

- Cotton rubbing cloth.

- Gray scale for staining.

- Light box.

- Scissor

- Fabric Sample.

Preparation of Specimen:

Two pieces not less than 14cm×5cm are required for dry rubbing and two for wet rubbing. One specimen of each pair shall have the long direction parallel to the warp yarns and other parallel to the weft yarns.

Test Procedure of Colorfastness to Rubbing:

Colourfastness to rubbing is carried out two way. one is dry condition where cotton rubbing cloth dry condition, other way is wet condition where cotton rubbing cloth wetted by using distilled water. we will description both procedure in this article.

Dry Rubbing Test:

- For testing, lock the test specimen onto the crockmeter’s base so that it lies flat and taut. The length or width direction of the test specimen should be parallel to the direction of rubbing.

- The white cotton rubbing test cloth should be set to the finger of the crockmeter using the spiral spring clip. Test cloths should have a parallel weave to the direction of rubbing.

- Now, place the covered finger on the test sample.

- Using the handcrank, turn the crank ten times at a rate of one turn per second.

- Then, to determine color transfer, remove the white rubbing test cloth from the finger, then use a gray scale to evaluate staining under the light box.

- Same way, the warp direction is tested once, and the weft direction is tested twice.

Wet Rubbing Test:

- Repeat procedure from 1 to 6 which is mentioned dry rubbing test procedure for another sample with the white cotton test cloth wetted in distilled water. Ensure that the rubbing test cloth will be wetted with water to 100% take up.

- Air dries the cotton test cloth at the room temperature before evaluation.

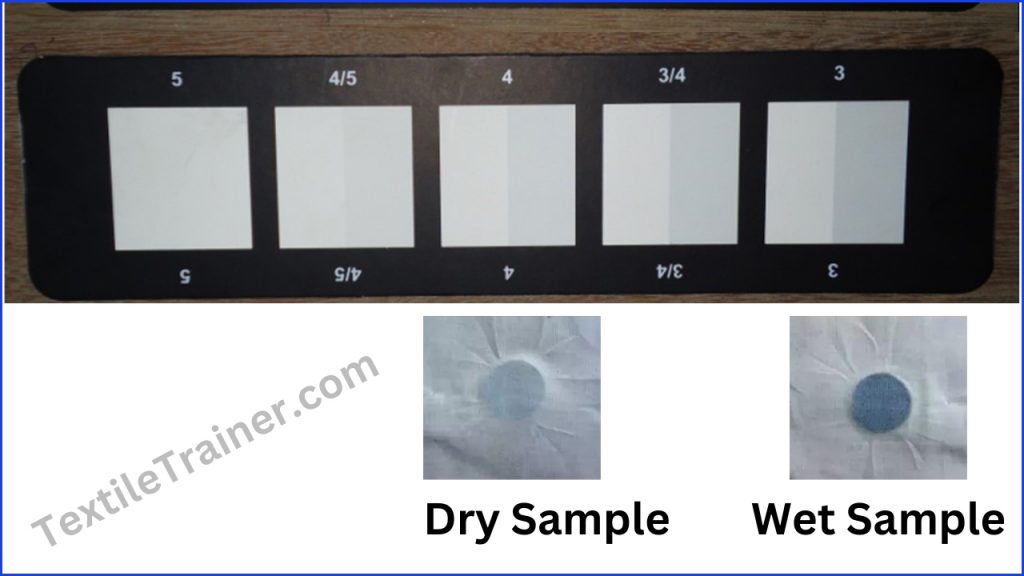

Evaluation & Result:

Compare the contrast between the untreated and treated white rubbing cloth with the staining grey scale and rate from 1 to 5 and changing in the tested specimen with changing grey scale. This visual assessment is done in a color matching cabinet under standard lighting D65.

| Staining | Warp Direction | Weft Direction | Avg. Grade |

| Dry | 4 | 4-5 | 4-5 |

| Wet | 3 | 3 | 3 |

Conclusion:

In dry condition, our sample show grade 4-5. From the standard table we evaluated our tested sample is good to rubbing in dry condition. In wet condition, it show avg. grade 3 which is fair color fastness to rubbing. This experiment will help in our future life. Thanks to our teacher to help us.

I really enjoy the blog article.Really thank you! Keep writing.

thanks too…

I value the post. Keep writing.

keep visit our site….

I appreciate you sharing this post.Thanks Again. Fantastic.

Keep visit our site….

Wow, great article.Much thanks again. Fantastic.

keep visit our site…..

Very informative blog.Thanks Again.

keep visit our site…..

Im obliged for the blog article.Really looking forward to read more. Keep writing.

ok…

Thanks so much for the article.Really thank you! Great.

keep visit our site…

I think this is a real great blog post.Really looking forward to read more.

keep visit our site.

Major thanks for the article post. Keep writing.

Keep visit our site…

A round of applause for your blog.Thanks Again.

thanks too….

Very good blog post.Much thanks again. Will read on…

Aw, this was an exceptionally nice post. Spending some time and actual effort to create a superb articleÖ but what can I sayÖ I put things off a whole lot and never manage to get anything done.

You can certainly see your expertise within the work you write.The world hopes for more passionate writers suchas you who aren’t afraid to say how they believe. All the time go after your heart.

Thanks

That is a good tip particularly to those fresh to the blogosphere. Short but very precise informationÖ Thanks for sharing this one. A must read article!

Thanks. Stay with us

Asking questions are truly nice thing if you are not understanding anythingfully, but this paragraph gives fastidious understanding even.

For years, companies have structured their business strategies around the funnel, but not anymore

It’s fantastic that you are getting thoughts from this paragraph as wellas from our dialogue made here.Here is my blog post Burst Audio Earbuds

Thank you

Very good post. Really Cool.

Thanks a lot for the article.Much thanks again. Want more.

I really like and appreciate your article.Really thank you! Want more.

Im grateful for the blog.Really thank you! Really Cool.

A big thank you for your blog article.Really thank you! Really Great.

thanks too….

Wow, great blog article. Want more.

ok, we will try.

Very good blog article.Much thanks again. Cool.

Say, you got a nice blog article.Really looking forward to read more. Awesome.

Greetings! Very helpful advice within this post! It’s the little changes that make the most important changes. Thanks for sharing!

Really appreciate you sharing this article post.Really thank you! Fantastic.

Great, thanks for sharing this article post.Really thank you! Fantastic.Loading…

Perfect to be here and read something interesting like your blog.

A round of applause for your article post.Thanks Again. Keep writing.

keep visit our site…

A big thank you for your blog.Really looking forward to read more. Want more.

ok…

Thank you for your blog post.Really looking forward to read more. Really Cool.

keep visit our site…….

I truly appreciate this blog.

You’re therefore amazing. Oh my Jesus. The almighty bless you.

Im obliged for the article.Really thank you! Fantastic.

Howdy just wanted to give you a brief heads up and let you know a few of the pictures aren’t loading properly. I’m not sure why but I think its a linking issue. I’ve tried it in two different internet browsers and both show the same outcome.

Thank you

Great, thanks for sharing this post. Really Great.

Very good blog article.Really looking forward to read more. Awesome.

Im obliged for the blog post.Much thanks again. Keep writing.

Im thankful for the article post.Much thanks again. Much obliged.

A big thank you for your post.Thanks Again. Cool.

Really informative blog article.Really looking forward to read more. Really Great.

I really enjoy the article.Really looking forward to read more. Really Cool.

Thank you for your article post. Much obliged.

Im thankful for the blog post.Much thanks again. Will read on…

Really appreciate you sharing this blog post.Much thanks again. Keep writing.

Appreciate you sharing, great post.Thanks Again. Really Great.

Im thankful for the blog.Much thanks again. Really Great.

Really informative post.Really thank you! Much obliged.

Really appreciate you sharing this blog.Thanks Again. Great.

I am so grateful for your blog article.Really thank you!

Thanks so much for the article.Really thank you! Really Cool.

Fantastic blog article.Really looking forward to read more. Keep writing.

Im obliged for the blog.Really looking forward to read more. Keep writing.

wow, awesome blog post.Really thank you! Keep writing.

Thank you for sharing bro, it’s a nice post..!!!!!

Aw, this was a very good post. Spending some time and actual effort to generate a great articleÖ but what can I sayÖ I procrastinate a whole lot and don’t seem to get anything done.

Thanks

Very informative post. Will read on…

Thanks. Stay connected

Appreciate you sharing, great article post.Thanks Again. Really Great.

Im grateful for the article post.Really looking forward to read more.

Fantastic blog article.Thanks Again. Really Cool.

Thanks a lot for the article.Thanks Again. Really Cool.

it is really informative. I am gonna be careful

Say, you got a nice article post.Much thanks again.

Im grateful for the post.Thanks Again. Really Cool.

I think this is a real great blog article.Really thank you! Really Great.

I really enjoy the blog post.Really looking forward to read more. Will read on…

Thanks for the blog post.Thanks Again. Cool.

I am so grateful for your blog.Really looking forward to read more. Awesome.

Very good article post.Really thank you! Cool.

Wow, great blog article.Really thank you! Really Cool.

Major thankies for the blog.Really thank you! Really Great.

Thank you for your article.Thanks Again. Cool.

Very good blog post.Thanks Again.

Thank you ever so for you article post.Thanks Again. Awesome.

Really enjoyed this blog post.Much thanks again. Great.

Im grateful for the blog post.Really thank you! Keep writing.

Thanks so much for the blog. Really Cool.

Im grateful for the post.Really looking forward to read more. Fantastic.

I really liked your blog.Really looking forward to read more. Much obliged.

Really appreciate you sharing this blog article.Thanks Again. Really Great.

This is one awesome post.Really thank you! Awesome.

Im grateful for the blog.Much thanks again. Awesome.

A big thank you for your article.Thanks Again. Will read on…

Fantastic blog article.Really thank you! Keep writing.

Enjoyed every bit of your blog.Thanks Again. Keep writing.

Very informative blog article.Much thanks again.

Thanks for sharing, this is a fantastic blog post.Much thanks again. Will read on…

Awesome blog post. Cool.

Thank you ever so for you post.Really thank you! Awesome.

Thanks for sharing, this is a fantastic blog post. Cool.

Thanks for the post.Much thanks again. Really Great.

Great blog.Much thanks again. Really Great.

Very informative article.

Very neat post.Really looking forward to read more. Really Cool.

Very informative post.Thanks Again. Great.

Great, thanks for sharing this blog post.Much thanks again. Awesome.

I really enjoy the post.Really looking forward to read more.

wow, awesome blog post. Really Great.

Major thanks for the blog article.

Hello, its nice post on the topic of media print, we all understand media is a great source of information.

I am so grateful for your article.Really thank you! Want more.

Awesome article post. Much obliged.

I loved your article.Really thank you! Great.

Hey, thanks for the post. Awesome.

I value the post.Thanks Again. Cool.

There is definately a lot to learn about this topic. Ilove all the points you have made.

Thanks for the article.Really thank you! Will read on…

Thanks a lot for the article.Much thanks again. Cool.

Thank you for your blog post.Really looking forward to read more. Fantastic.

Thank you ever so for you article post.Thanks Again. Much obliged.

I loved your blog.Much thanks again. Much obliged.

I cannot thank you enough for the blog article. Keep writing.

Looking forward to reading more. Great blog post. Fantastic.

I really enjoy the blog post.Thanks Again. Will read on…

Thanks for the blog article.Really thank you! Really Cool.

This is one awesome post. Much obliged.

I truly appreciate this article post. Keep writing.

Very informative article.Really thank you! Awesome.

Hey, thanks for the blog post. Much obliged.

Thanks for the article post. Keep writing.

I really liked your blog post.Much thanks again. Cool.

Wow, great blog article. Fantastic.

Really appreciate you sharing this blog post.Much thanks again. Great.

I appreciate you sharing this post. Great.

I think this is a real great blog.Thanks Again. Awesome.

Very good article post.Much thanks again. Want more.

Thank you ever so for you blog. Much obliged.

Awesome blog post. Really Cool.

I value the article.Thanks Again. Cool.

Enjoyed every bit of your article post.

Thank you for your blog.