Introduction:

Sweat from the human body is a complex chemical containing large amounts of salt. Depending on the human metabolism, it can either be acidic or alkaline. Colorfastness to perspiration is tested using solutions prepared by simulating acidic and alkaline sweat.

Colorfastness to perspiration test determines how resistant a dye is to perspiration in textiles of all kinds. A color fastness level of 3-4 (color change and staining) is required for perspiration (acid and alkaline). This criterion does not apply to white products, products that are neither dyed nor printed, or fabrics intended for furniture, curtains, or other interior decoration purposes. When fabrics that are both light colored (standard depth 1/12) and made of silk or blends with at least 20% silk are permitted to be rated at level 3. It is applied explicitly to sportswear and heavy dresses used primarily for sports. Perspiration tests are also conducted on normal clothes.

Objectives:

- To know about colourfastness to perspiration.

- To know required chemical name for perspiration test.

- Come to learn working procedure of perspiration test.

Colored textiles in contact with other fiber materials (for color transfer) are immersed in simulated acid perspiration solution, subjected to a fixed mechanical pressure, and allowed to dry gradually at a slightly elevated temperature. The specimen is evaluated for the color change, and the other fiber materials are evaluated for color transfer after conditioning. These are the principles of colorfastness to perspiration.

Apparatus:

- Perspiration tester.

- Oven.

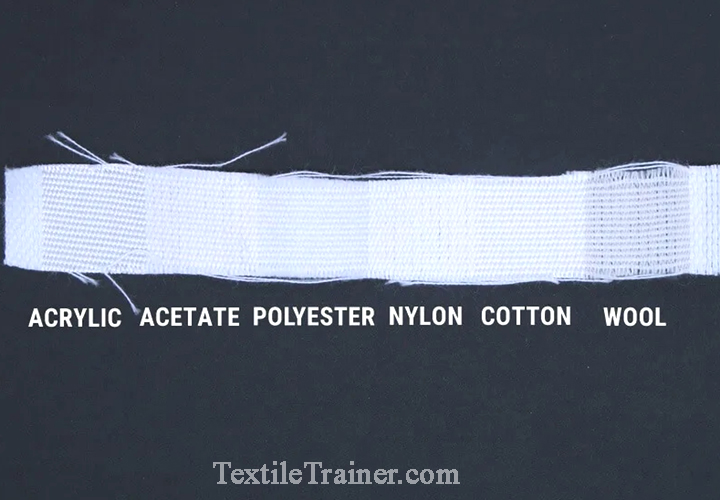

- Multifiber test fabric.

- Grey scale for color changing.

- Grey scale for color staining.

- Standard light box.

- Acid and alkaline solution.

- Non-dyeable fabric.

- Glass plates.

- Scissor.

Test specimen preparation:

- Cut two identical 10cm×4cm specimens. If the fabric sample is multi-coloured take as many specimens as necessary to ensure that all colors will be in contact with each of the six fiber bands of the multifiber adjacent fabric.

- Attach the multifiber adjacent fabric of equal size to the test specimens by sewing along one of the shorter sides with the multifber fabric in contact with face of the specimens. This is the composite test specimens.

Required Chemical:

| Chemical name | Acid Perspiration test | Alkaline Perspiration test |

| L-Histidine mono-hydrochloride mono-hydrate (C6H9O2N3HCl.H2O) | 0.5 gm | 0.5 gm |

| Sodium Chloride (NaCl) | 5.0 gm | 5.0 gm |

| Disodium hydrogen orthophosphate dehydrate (Na2HPO4.2H2O) | 2.2 gm | 2.5 gm |

| Distilled water | 1000ml | 1000ml |

| PH (Adjust with 0.1N NaOH) | 5.5 | 8.0 |

Test Procedure of Colorfastness to Perspiration:

- Wet the composite test specimen at room temperature with the mentioned perspiration solution. Leave for 30 minutes with a liquor ratio of 50:1.

- Pour off excess solution and place this composite test specimen between two glasses plates under a pressure of 12.5 KPa and then place in an oven for 4 hour at 37±20 C

- Remove the specimen and hang to dry in warm air not exceeding 600 C.

- Don’t press or iron the specimen or the multifiber test fabric.

- Now, compare specimen and multifiber with color straining and color changing grey scale.

Standard Value for Fastness:

According to ISO-105-E04

| Color fastness grade | Fastness properties |

| Grade-5 | Excellent |

| Grade-4 | Good |

| Grade-3 | Fair |

| Grade-2 | Poor |

| Grade-1 | Very poor |

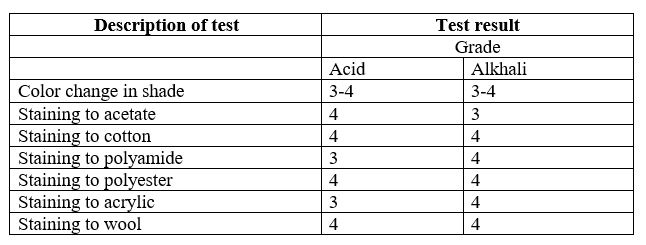

Result:

Numerically rate the colour change and staining of each test specimen under standard light using the grey scales for color change and color staining.

Conclusion:

The garments which come into contact with the body where perspiration is heavy may suffer serious local discolouration. one precaution of this experiment that, don’t apply the acid and alkaline perspiration testing at a time. However, from this experiment, we came to learn details about colorfastness to perspiration of dyed fabric. we also learnt different chemical name and how to make acid and alkhali solution. We also learnt working procedure of colorfastness to perspiration test. Thanks to our teacher to help us.

clarification for fabric size and multi fiber size

I clarified fabric size….but not multi fiber…..ok….I will clarify……thanks for your good suggestion….

Your method of explaining all in this article is genuinely fastidious, everyone be capable of effortlessly be aware of it, Thanksa lot.

thanks too…please stay with us.

Thanks so much for the post.Really thank you! Keep writing.

Keep visit our site….

I think this is a real great post.Really thank you! Want more.

keep visit our site…

Im grateful for the blog article.Much thanks again.

thanks for stay

Thanks a lot for the post.Much thanks again. Great.

thanks for support.

A round of applause for your blog.Really looking forward to read more. Keep writing.

keep visit.

I loved your blog post.Much thanks again. Want more.

ok, I will try.

Really informative blog article.Really looking forward to read more. Will read on…

Stay with us

Hello mates, its enormous post regarding tutoringand fully defined, keep it up all the time.

thanks too….please support us.

over the internet. You actually understand how to bring an issue to light and make it important.

Thanks. Stay with us.

What’s up to all, for the reason that I am genuinely keen of reading this blog’s post to be updated on a regular

Thanks-a-mundo for the blog post.Really looking forward to read more. Really Cool.

Fantastic blog post.Thanks Again. Really Cool.

thanks too…

Thanks so much for the article.Really looking forward to read more. Fantastic.

keep visit our site….

I like what you guys tend to be up too. Thiskind of clever work and coverage! Keep up the superb works guys I’ve included you guys tomy personal blogroll.

I value the article post.Really thank you! Much obliged.

Say, you got a nice article. Much obliged.

Thanks again for the article post.Thanks Again.

Thanks for sharing such a nice opinion, paragraph is pleasant, thats why i have read it entirely

Im obliged for the blog article.Really thank you! Keep writing.

I want to to thank you for this good read!! I definitely loved every bit of it. I’ve got you saved as a favorite to look at new things you post…

I appreciate you sharing this article.Much thanks again.

Thanks too…

I loved your blog.Much thanks again. Great.

keep visit our site.

Thank you ever so for you article.Really thank you! Really Cool.

Thank you for your blog post.Thanks Again. Awesome.

Great blog.Really thank you! Really Great.

Awesome post.Really thank you! Want more.

Very informative post.

I really enjoy the article post.Really looking forward to read more. Want more.

I loved your article post.Really thank you! Great.

Really informative post.Really thank you! Much obliged.

Wow, great blog post.Really thank you! Will read on…

I truly appreciate this post. Keep writing.

I really liked your blog article.Much thanks again. Keep writing.

I really like and appreciate your article. Really Great.

Very good article.Really looking forward to read more. Keep writing.

Major thanks for the article.Much thanks again.

This was an excellent article. I loved it. I’ll return to read some more. Thanks !

Thank you ever so for you post.Thanks Again. Awesome.

I am so grateful for your article post. Really Cool.

I think this is a real great blog article.Much thanks again. Awesome.

I loved your post.Much thanks again. Will read on…

Very good article.Much thanks again. Want more.

Thanks again for the blog article.Really looking forward to read more. Will read on…

Im grateful for the article.Much thanks again. Cool.

Fantastic article.Much thanks again. Fantastic.

Thanks a lot for the post. Really Great.

I really like and appreciate your blog post.Really looking forward to read more. Really Great.

I loved your blog article. Great.

Great, thanks for sharing this article.Much thanks again. Awesome.

Thank you for your blog. Cool.

Awesome article.Thanks Again. Fantastic.

Im obliged for the post.Really thank you! Really Great.

Thanks a lot for the article post.Much thanks again. Cool.

I appreciate you sharing this blog post.Much thanks again. Want more.

Great, thanks for sharing this blog.Really thank you! Much obliged.

I truly appreciate this article.Really looking forward to read more. Great.

Looking forward to reading more. Great article.Really looking forward to read more. Really Cool.

Wow, great article post.Really looking forward to read more.

Thank you ever so for you blog post.Much thanks again. Cool.

Wow, great post.Thanks Again. Keep writing.

A big thank you for your blog. Will read on…

I really enjoy the blog.Thanks Again. Cool.

Im thankful for the article.Thanks Again. Awesome.

I really liked your blog post. Great.

Great article post. Great.

A round of applause for your article post.Really thank you! Will read on…

Looking forward to reading more. Great blog. Really Great.

I truly appreciate this article.Thanks Again.

Great, thanks for sharing this blog.Much thanks again.

Thanks again for the article post.

wow, awesome post.Much thanks again. Will read on…

I value the post.Thanks Again. Want more.

Thanks

Really informative blog article. Want more.

Thanks

I appreciate you sharing this blog article. Really Cool.

Major thanks for the post.

I really liked your post. Fantastic.

I think this is a real great blog article.Thanks Again. Really Great.

Major thankies for the blog post.Thanks Again. Awesome.

I appreciate the manner you have ended this blog post …

Very neat article post.Really thank you! Want more.

Really enjoyed this blog article.Thanks Again. Cool.

This is one awesome article. Will read on…

I truly appreciate this post.Really thank you! Much obliged.

Really enjoyed this blog post.Really looking forward to read more. Keep writing.

Thanks a lot for the blog post.Much thanks again. Cool.

Very informative post.Thanks Again.

I value the article.Much thanks again. Awesome.

Kerassentials are natural skin care products with ingredients such as vitamins and plants that help support good health and prevent the appearance of aging skin. They’re also 100% natural and safe to use. The manufacturer states that the product has no negative side effects and is safe to take on a daily basis.

Thanks so much for the article post. Much obliged.

Say, you got a nice blog.Really thank you! Fantastic.

Thanks for sharing, this is a fantastic post.Much thanks again. Keep writing.

I appreciate you sharing this blog.Much thanks again. Fantastic.

Really appreciate you sharing this blog.Much thanks again. Fantastic.

Very neat post.Much thanks again. Really Cool.

This is one awesome blog article.Thanks Again. Cool.

I really like and appreciate your post.Thanks Again. Will read on…

Very informative article post.Thanks Again. Great.

wow, awesome blog article. Really Cool.

I truly appreciate this blog post.Thanks Again. Cool.

Thanks so much for the post.Really thank you! Awesome.