Name of the Experiment:

Study on different types of seam used in garments manufacturing.

Introduction:

A seam is the line along which many layers of fabric are joined together. This seam can be made by sewing or by joining fabrics in another method. A sewing project is aimed at making a seam that looks good and performs well, in order to make it as of standard quality and at a reasonable cost. If a seam has a good appearance, the stitches in the seam are of the correct size and do not harm the fabric. Also, the fabric along the sewing line will remain smooth and there will be no gathering. Though gathering is not allowed in seams, sometimes gathering is intentionally created for the purpose of creating a design. In fabrics of various types and constructions, seams are made to look good using a variety of techniques. As long as the appearance of seams is intact during the use of the garments or during the washing of the garments after they have been made, it is essential to ensure that these seams will not fade. A seam’s qualities can be determined by its strength, elasticity, durability, security, and any special characteristics of the fabric, for instance, water resistance or flame resistance.

Objectives:

- To understand the definition of seam, take a look at the following

- To understand different types of seams.

- To know what types of seams are used for what purposes.

- Identifying and analyzing garment seam classes.

- Comparing the appearance and finish of different seam classes.

Types of Seam:

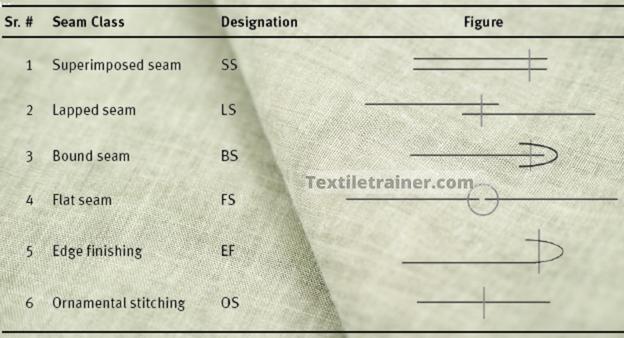

There are hundreds of types of seams, and these have been classified into six classes. However, now that two more types of seams have been added, a total of eight classes have been established and each type of seam will be discussed with the help of the diagram below.

- Class-1: Super imposed seam.

- Class-2: Lapped seam.

- Class-3: Bound seam.

- Class-4: Flat seam.

- Class-5: Decorative seam.

- Class-6: Edge neatening seam.(over lock)

- Class-7: Applied seam.

- Class-8: Enclosed seam.

My goal now is to describe all the seam classes in detail along with a proper image as mentioned above.

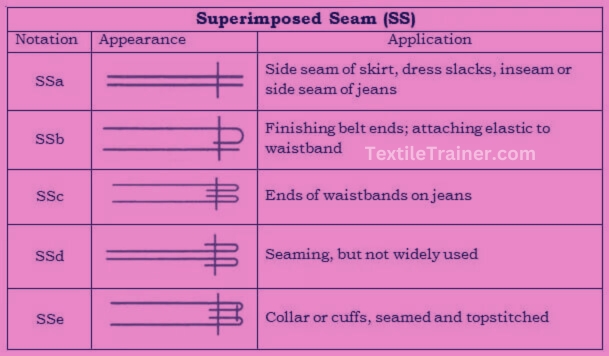

Class-1: Super imposed seam:

In garment sewing, this type of seam is the most common. To create this seam, one end of a fabric is placed on the other end and then the seam is sewn. The sewn edge or the edges usually remain the same direction. Various types of stitches are used for making this type of seam. It can be used to join fabrics or to neaten edges by sewing the ends or both jobs. In the assembly of shirts, blouses, skirts, trousers, dresses, and other garments, they are often used, especially in the seams of shirts or pants. It is important to note, however, that superimposed seams are not appropriate for stretch fabrics or areas that require additional strength and stretch ability. Overall, superimposed seams offer a clean and straightforward means of joining fabric layers. This technique provides an aesthetically pleasing and reliable seam finish, making it useful in the construction of various garments.

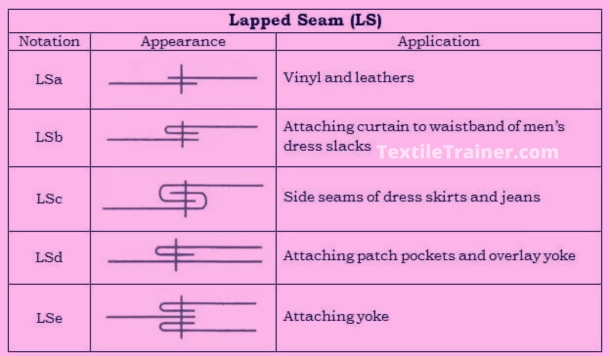

Class-2: Lapped seam:

In this type of seam, at least two fabrics are sewn together. The ends of the fabrics are usually reversed along the seam line and the one’s end overlaps the other. Lapped seams are constructed by placing one fabric edge on top of another fabric piece with a desired overlap width, then stitching along the edge, typically with a straight stitch. They offer a number of advantages for garment construction. Typically, they are used in heavy or structured fabrics where additional reinforcement is needed in areas of high stress, such as waistbands, pocket openings, or hems.

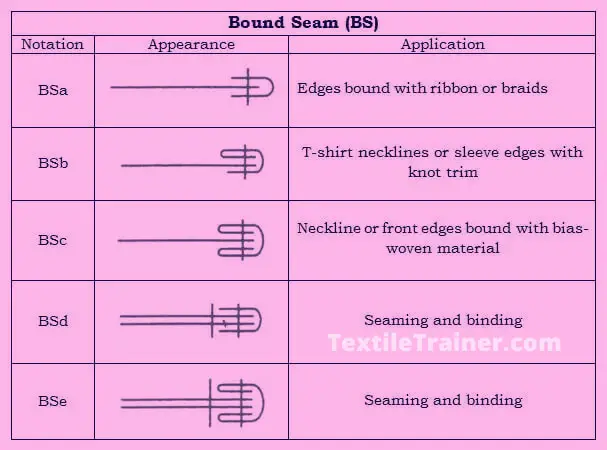

Class-3: Bound seam:

A bound seam is a type of seam where the raw edges of the fabric are enclosed and finished with a separate strip of fabric called binding. As well as providing a clean and professional finish, it adds strength and durability to the garment as well. The construction of a bound seam involves aligning the fabric edges and placing a strip of binding fabric over the raw edges. Binding is then stitched in place, enclosing the raw edges within the seam. The binding can be cut from a matching or contrasting fabric, depending on the desired aesthetic effect. Bound seams are versatile and can be used in a variety of garments and fabric types. A bound seam provides a clean and refined finish to garments such as blouses, dresses, and lingerie, where a clean and refined finish is desired. They are particularly useful for lightweight and delicate fabrics prone to fraying, as the binding protects and strengthens the seam.

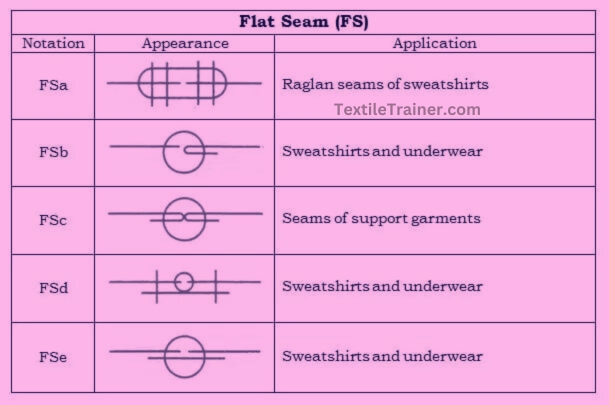

Class-4: Flat seam:

This type of seam is formed by joining the ends of two fabrics, but they stay side by side so that one end does not overleap the other. Some seams are made for decorative purposes by leaving a gap between the ends of the fabric. With the help of another covering thread, the threads of the two needles are continuously connected, making flat seams by twin needle machines. There is a system of automatically cleaning the ends of the fabric just before the seam is made. This type of seam has a relatively thin thickness and is often used in garments which are knitted and in underwear.

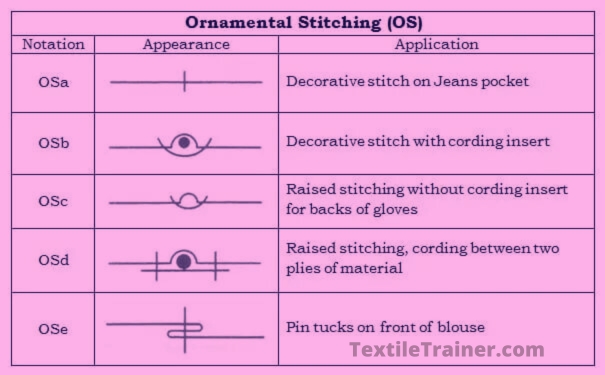

Class-5: Decorative seam:

A decorative seam was previously known as decorative stitching. It is made and used mainly for enhancing the beauty and decoration of garments, and for this reason it was called decorative stitching. It is a seam that is made by stitching multiple lines of stitching side by side within one or more layers of fabric. A multi needle sewing machine and folder with it are required for this type of seam. In addition to adding a distinctive touch to garments, decorative seams can be used strategically to highlight specific design elements, create focal points, or simply enhance the overall aesthetic appeal. It is also called ornamental stitching.

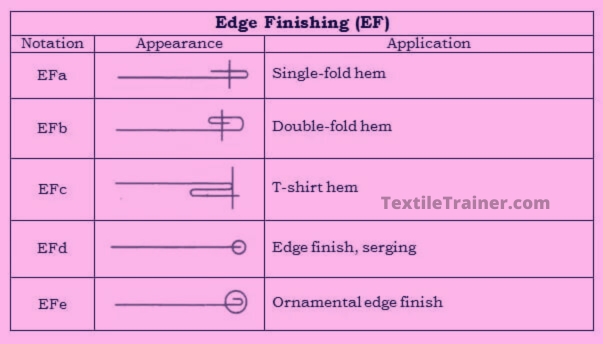

Class-6: Edge neatening:

The edge neatening seam, also known as an edge finishing seam, provides a professional finish to a garment. It is particularly important when dealing with fabrics that tend to unravel. As a way to prevent raw fabric edges from fraying or unraveling over time, edge neatening seams enclose or protect them. In order to achieve a professional and polished appearance in garment construction, edge neatening seams are essential to enhance durability and longevity. The choice of edge neatening method depends on factors such as fabric type, garment design, and desired finish. This seam is made by overlock machine.

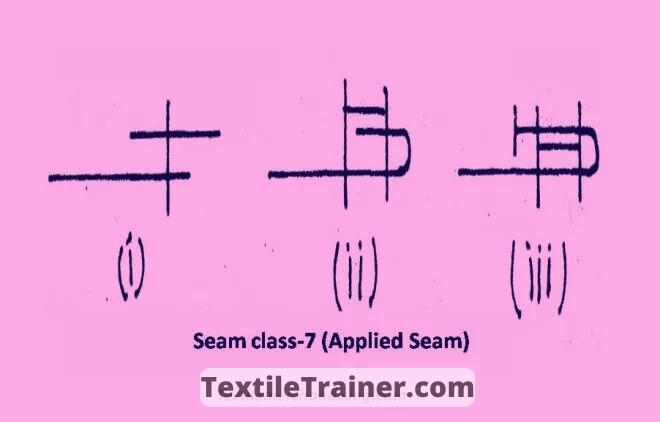

Class-7: Applied seam:

This types of seams are largely similar to lapped seams, but the component which is joined at the end of the fabric, is extended from the sewing line limited on both sides.This type of seams are mainly used for joining of additional item at the ends of the fabrics. Multiple thread sewing machines and folders are much helpful for making this type of seams.

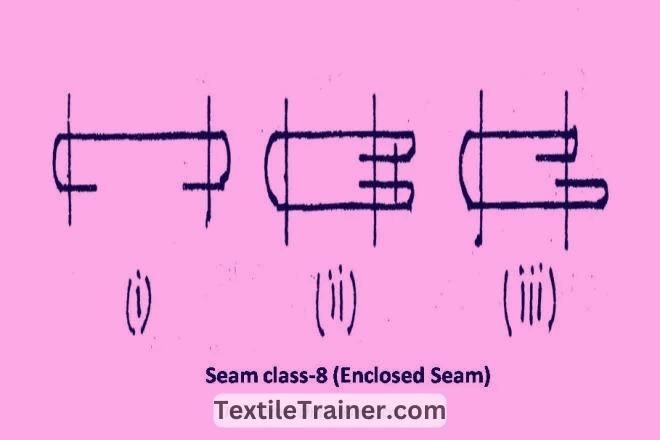

Class-8: Enclosed seam:

In this type of seam, the edges of the fabric are folded variously and then sewn. Belt loops and belt straps are also made with these type of seams. Folders are very useful in making these kinds of seams. Twin needle sewing machines and folders make it possible to make multiple seams at once. Enclosed seams offer several advantages in garment construction. They ensure a professional finish, prevent fraying, and increase durability. Generally, enclosed seams are found in high-end garments, lingerie, and lightweight fabrics where a smooth, polished appearance is desired.

Conclusion:

We have gained valuable insight into the various techniques and methods used in garment construction as a result of studying different kinds of seam classes. As a result of studying seam classes like superimposed seams, lapped seams, flat seams, decorative seams, edge neatening seams, and enclosed seams in the fashion industry, we have gained an in-depth understanding of their uses, advantages, and applications. It was a pleasure to work with our teacher.