Introduction:

Several factors determine the extent of sewing thread consumption calculation. Factors affecting sewing thread consumption calculation are stitch type, number of layers, seam type, SPI (stitches per inch), material thickness, and construction. However, these factors are not constant with the different style preferences. That’s why, thread consumption is never standard for sewn product categories. From this article, you can learn how to calculate sewing thread consumption. Here, I also present the sewing thread consumption formula.

Sewing Thread Consumption Calculation

There are two methods used for sewing thread consumption calculation. They are:

- By measuring the actual amount of thread.

- By calculation using thread consumption ratio.

1. By Measuring the Actual Amount of Thread

To calculate actual amount of sewing thread consumption, we have to follow the below step.

- Step 1: At first, measure a specific length of the seam.

- Step 2: Now, pull out the thread from this measured length.

- Step 3: Calculate the thread factor. To calculate the thread factor, divide the amount of thread by the original stitch length.

- Step 4: Now, multiply this thread factor ratio by the total length of the seam. This result is actual thread consumption

Actual sewing thread consumption formula

- Thread factor= = thread length ÷ original stitch length

- Actual thread consumption= length of the seam × thread factor ratio.

Let’s see an example. From this example, you can easily learn, how to calculate the actual sewing thread consumption for a garment.

Example : Calculate the actual sewing thread consumption, if the length of the seam is 20 cm for a 2 thread chain stitch (402). Add 5% waste.

Solution:

Here,

- Length of seam = 20 cm

- Needle thread length after removed from the seam = 24.5 (assumed)

- Looper thread length after removed from the seam = 65 cm (assumed)

- Thread consumption for 2 meter (200 cm)

- Needle thread factor= = needle thread length ÷ original seam length= 24.5 ÷ 20= 1.2

- Looper thread factor= Looper thread length ÷ original seam length= 65 ÷ 20= 3.25

- Actual needle thread consumption= length of the seam × thread factor ratio= 200 × 1.2= 240 cm

- Actual looper thread consumption= length of the seam × thread factor ratio= 200 × 3.25= 650 cm

- Total thread consumed= Needle thread + looper thread = 240 + 650 = 890 cm

- Total thread consumed with wastage= 890 × 1.05= 934.5 cm

- N.B.: Generally, 5-15% wastage of thread is added when calculating thread consumption. This waste occurs due to machine running, repairs, and thread breakage, etc. In the above example, I show one thread consumption calculation for one type of stitch class in a garment. By following this procedure of thread consumption calculation, you can calculate thread consumption for different types of stitches in a garment.

2. By Calculation Using Thread Consumption Ratio:

This method of thread consumption calculation is easier than other method that’ve been described above. Here, a standard thread ratio is used for different types of stitches. Thread consumption ratio for different stitch types and machines are listed below.

| Stitch class | Description | No. of needles | Needle thread% | Looper thread% | Thread ratio |

| 301 | Lock stitch | 1 | 50 | 50 | 2.5 |

| 101 | Chain stitch | 1 | 100 | 0 | 4.0 |

| 401 | Two thread chain stitch (overlock) | 1 | 25 | 75 | 5.5 |

| 304 | Zigzag lock stitch | 1 | 50 | 50 | 7.0 |

| 503 | Two thread over edge stitch (overlock) | 1 | 55 | 45 | 12.0 |

| 504 | Three thread over edge stitch (overlock) | 1 | 20 | 80 | 14.0 |

| 512 | Four thread mock safety stitch (over lock) | 2 | 25 | 75 | 18.0 |

| 516 | Five thread safety stitch (overlock) | 2 | 20 | 80 | 20.0 |

| 406 | Three thread covering stitch (flat lock) | 2 | 30 | 70 | 18.0 |

| 602 | Four thread covering stitch (flat lock) | 2 | 20 | 80 | 25.0 |

| 605 | Five thread covering stitch (flat lock) | 3 | 30 | 70 | 28.0 |

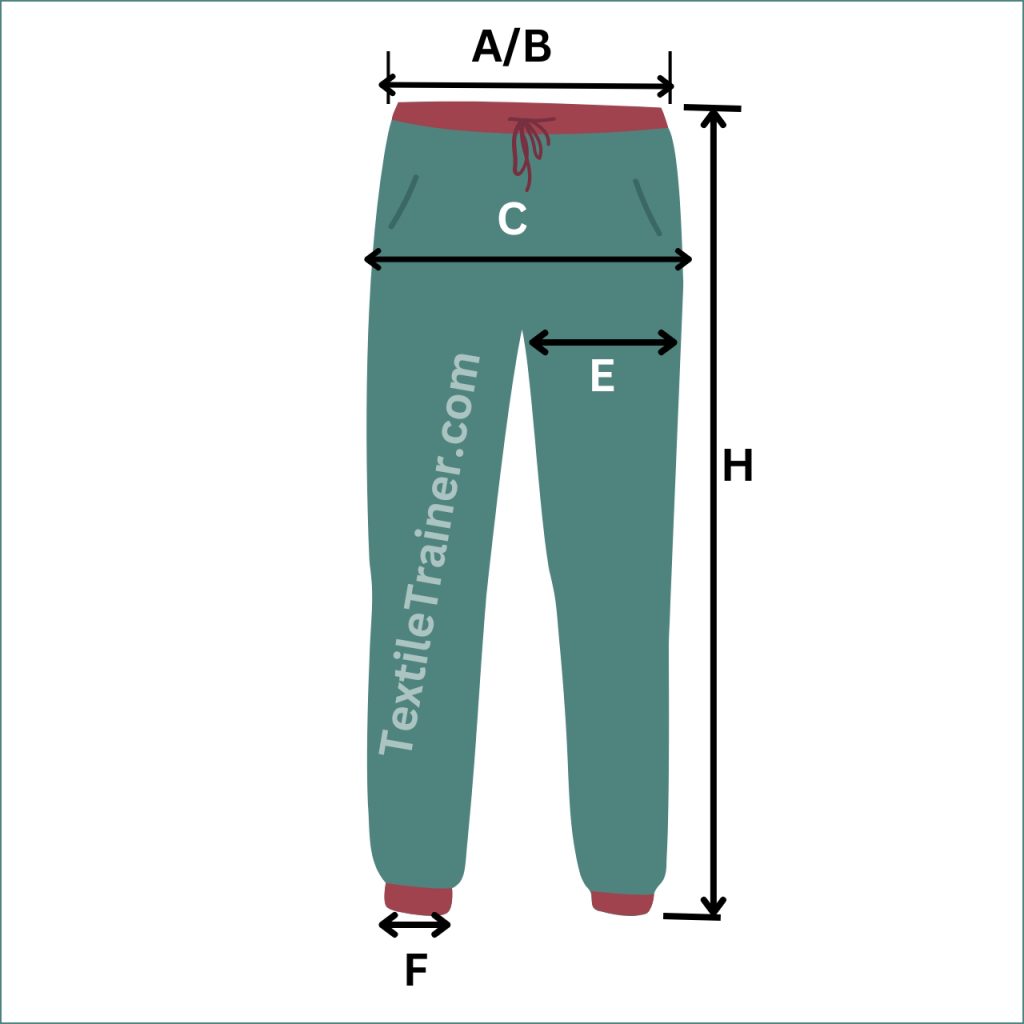

Example : suppose, we got an order for girl’s night pant with the order quantity is 10,000 pcs from Zara buyer. The average rejection rate of your company is 5%. All the sewing process are needs to be done with 3 thread over lock, and top stitch at waistband, ankle rib and side seams with 5 thread flat lock machine . Consider that all needle threads are green and looper threads are in red color. Now calculate total sewing thread quantity required to complete the order, also mention the color wise requirement.

| Measurement | ± | S | M | L | XL | |

| A | ½ waist measurement relaxed | 1 | 20.5 | 21 | 21.5 | 22 |

| B | ½ waist width stretched, pull one | 1 | 25 | 26 | 27 | 28 |

| C | ½ hip width | 1 | 28 | 29 | 30 | 31 |

| D | Hip position below the waistband | 0 | 8 | 8 | 8 | 8 |

| E | ½ width of thigh | 0.5 | 16 | 16.5 | 17 | 17.5 |

| F | ½ leg opening | 0.5 | 10.5 | 11 | 11.5 | 12 |

| G | Height of waistband | 0 | 3 | 3 | 3 | 3 |

| H | Outside leg including waistband | 1 | 28 | 32 | 36 | 40 |

| I | Front rise | 0.5 | 16 | 17 | 18 | 18 |

| J | Back rise | 0.5 | 19 | 20 | 21 | 22 |

N.B.: we should always consider the middle size for the thread consumption calculation. Let’s be clear, if there are sizes S, M, L, XL, and XXL consider the size L. But if the sizes are S, M, L, and XL, consider the size L. For our thread consumption calculation, we will consider the calculation for size L.

Solution:

- The provided order quantity = 10,000 pcs

- Total order quantity includes average rejection (5%) = 10,000 + (10,000×5%) = 10,500 pcs garments

Calculation of total seam length:

- Total seam length= (B×2) + {(H-G) ×2} + {(H-I) ×2} + (I-G) + (J-G) + (F×4)

- = (27×2) + {(36-3) ×2} + {(36-18) ×2} + (18-3) + (21-3) + (11.5×4)

- = 54+ 66+36+15+18+46 = 235 cm

- Total seam length 235 cm

N.B.:

- “ B” is half of the waist circumference. To get the full circumference of the waist, “B” is multiplied by 2. (B×2)

- For side seam, the full length of the garment is “H”. If we reduce the waistband from full length, we will get side seam length. (H-G)

- In the case of front and back rise, reduce the waistband width from the provided measurement.

- Here leg opening is half of the full circumference, hence leg opening is multiplied by 4.

For 3-thread overlock machine thread consumption:

From table 1, we know, 1 cm 3 thread overlock stitch consists of 14 cm sewing thread, in that 20% needle thread and 80% looper thread.

- For 235 cm stitch, the consumption = 235×14= 3,290 cm

- Needle thread consumption per garment is 20% of 3290 cm= 3290×20%= 658 cm/garment.

- Total needle thread for order quantity= 658×10,500= 69,09,000 cm or 69,090 meters

- Looper thread consumption per garment is 80% of 3290 cm= 3290×80%= 2,632 cm/garment.

- Total looper thread for order quantity= 2632×10,500= 2,76,36,000 cm = 2,76,360 m

For 5 thread flat lock machine thread consumption:

The flat lock machine is used in three places, such as, waistband, ankles rib, and side seam top stitch. On the other hand, 1 cm 5 thread flat lock stitch consists of 28 cm sewing thread, in that 30% for needle thread, and 70% for looper thread.

- Total waistband length= (B×2)= 27×2= 54 cm

- Side seam total length= {(H-G) ×2}= {(36-3) ×2}= 66 cm

- Ankle total length= (F×4)= 11.5×4= 46

- Total seam length= (waist band +side seam+ ankle length) = 54+66+46= 166 cm

- For 166 cm stitch, the consumption = 166×28 = 4,648 cm [1 cm 5 thread flat lock stitch consists of 28 cm sewing thread]

- Needle thread consumption per garment is 30%= 4648×30%= 1,394.4 cm/garment

- Total needle thread for order quantity= 1394.4×10,500= 1,46,41,200 cm or 1,46,412 m.

- Looper thread consumption per garment is 70%= 4648×70%= 3,253.6 cm/garment

- Total looper thread for order quantity= 3253.6×10,500= 3,41,62,800 cm or 3,41,628 m.

Color-wise thread requirement:

- Our needle thread color is green.

- Total length of needle thread= needle thread of overlock + needle thread of flatlock= 69090+146412= 2,15,502 m

- Industrial sewing threads generally available in 5,000 meter per cones

- Number of cone required= 2,15,502 ÷ 5,000 =43.1 or 44 cones

- Approximately 44 cones of green color are required to complete the order

- Our looper thread color is red.

- Total length of looper thread= Looper thread of overlock + looper thread of flatlock= 2,76,360 + 3,41,628 = 6,17,988

- Number of cone required = 6,17,988÷ 5,000= 123.5 or 124 cones

- Approximately 124 cones of red color are required to complete the order.

Factors Affecting Sewing Thread Consumption

Below, some factors affecting sewing thread consumption are listed. They are:

- Quality of thread.

- Automatic thread trimmer of the machine.

- Size of the garments.

- Types of stitch and density of stitch

- Thickness of the fabrics.

- Skill of the machine operator.

- Design of the garments.

- Seam width.

- How many plies of fabrics are to be sewn.

- Skill of merchandiser

Conclusion:

Every merchandiser in the garment industry should know the sewing thread consumption calculation. In this article, I tried my best to present an easy-to-use sewing thread consumption formula. In this article, you learned how to calculate sewing thread consumption. From this article, we also learned, how to calculate actual sewing thread consumption. However, if you have any questions about thread consumption calculation, let me know via the comments box.

You may read:

- Calculate Size Wise Order Quantity in Garments Industry : An Easy 3 Steps

- Easy Fabric GSM Calculation Formula for Woven Fabric and Knit Fabric with 5 Example

- Sewing Thread Consumption Shortcut Easy Formula with 5 Exercise

- Determination of fabric consumption calculation for woven basic pants by Easy Formula

- Calculation of Fabric Consumption for a Long Sleeve Basic Shirt in Easy Formula

- Apparel Analysis with Example : Easy 7 Steps of Polo Shirt Analysis