Types of Stitches Used in Garments with Proper Image

Name of the Experiment

Study on different types of stitches used in garments manufacturing.

Introduction

Stitches in garment manufacturing are formed by sewing one or more threads or thread loops through intralooping, or interlooping, or interlacing methods. These sewing actions are known as stitches. Stitching is the process of joining fabric pieces together with individual loops or lines of thread. It is made possible by passing a needle and thread through the layers of fabric, interlocking or interlacing them together.

A garment is constructed using various types of stitches, which serve various purposes, such as joining fabric pieces, creating decorative effects, reinforcing seams, or finishing raw edges. There are many factors to consider when choosing a stitch, such as fabric type, durability, and aesthetics. For a clear understanding of stitching, knowing the following three terms is necessary.

- Intralooping: This is the term used when the loop of a thread passes through the loop of another thread of the same thread; this is called intralooping.

- Interlacing: A thread or loop of the thread passes over another tread or loop of the thread when one tread passes over another one. This is called interlacing.

- Interlooping: A thread looping is a process that occurs when one loop passes through the loop of another thread, this is known as interlooping.

Objectives

- To know more about the classification and categorization of stitches.

- To know about Comparative Analysis of the characteristics of stitching and the suitability of stitching.

- Come to learn Application and Recommendations for stitch selection.

- Exploration of new stitching techniques and innovation in the stitching industry.

Types of Stitches

Approximately 70 types of stitches are used, out of which 18 to 20 types are primarily used by garment manufacturers. There are six classes of stitches. In tailor shops or in homes, 2 to 3 types of stitches are used to make garments. These six classes are:

- Stitch class-100 (chain stitch)

- Stitch class-200 (Hand stitch)

- Stitch class-300 (Lock stitch)

- Stitch class-400 (Multi thread chain stitch)

- Stitch class-500 (Over edge stitch)

- Stitch class-600 (Covering chain stitch)

Below we have discussed all the above types of stitches in more detail:

1. Stitch class-100 (Chain stitch)

A chain stitch is produced by passing a needle thread through a fabric, forming a needle loop, and then securing it with the next loop formed by the same thread. Chain stitches are characterized by intralooping. Stitches of this type are unsecured. If they break, they unravel very easily. A common stitch is stitch type-100 and a stitch type-101. As it is very unsecured, it is used for biasting operations, which are temporary stitching operations for positioning collars, cuffs, and flaps.

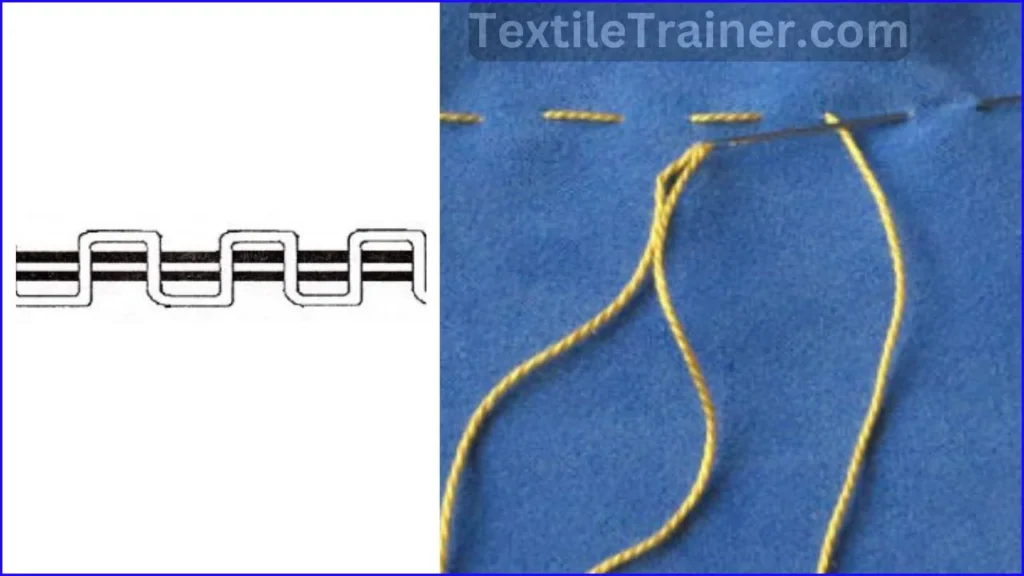

2. Stitch class-200 (Hand stitch)

A single thread is used to create this type of stitch. The thread is passed through the fabric from one side to another and the stitch is secured by the thread running through the garment from one side to another. As a time-consuming and costly operation, hand stitching requires high levels of skill. Stitch type-209 is used at jacket edges. This stitch is produced using a needle with a hole in the middle and a sewing machine. In most cases, this type of stitch is used in expensive dresses.

3. Stitch class-300 (Lock stitch)

Usually, two or more thread groups are used to create this type of stitch. In this case, the threads from two groups are interlaced. Loops from one group are passed through the material and secured by the thread from the second group. In this stitch, there are two groups, one is needle thread, the other is bobbin thread. Lock stitches have enough strength and appear the same on both sides. They are also extremely secure and do not unravel if the yarn breaks.

The disadvantage is that bobbins contain less thread and so run out during sewing. As a result, the bobbin is threaded again after sometimes which is time consuming and disgusting. Lock stitch is extensively used for joining fabrics collar, cuff, pocket, facing and so on. Top stitching is used for button holing, attaching, blind stitching, etc.

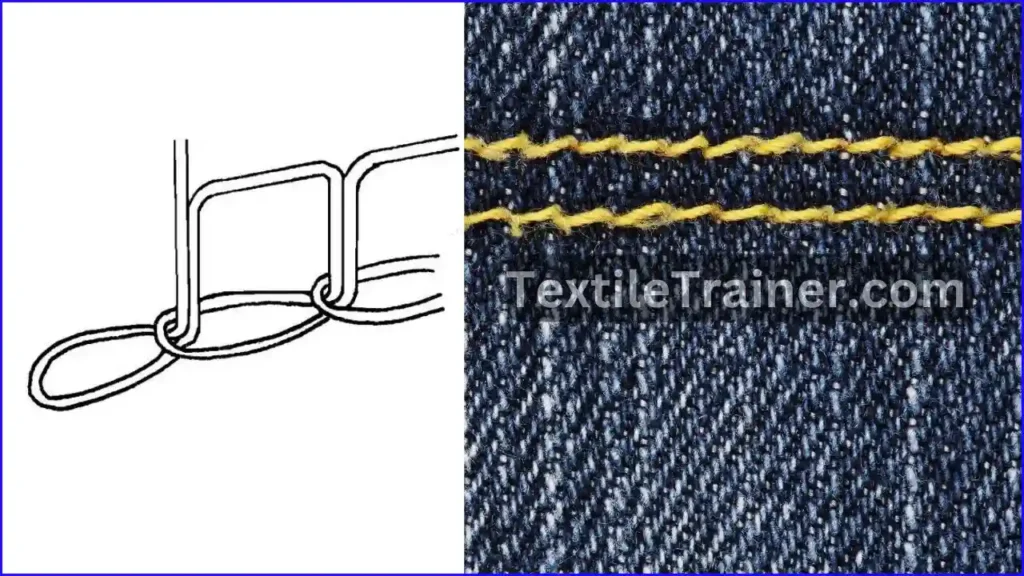

4. Stich class-400 (Multi thread chain stitch):

It consists of two or more groups of threads. The loops of one group pass through the material and are secured by interlacing and overlapping with loops of the other group. This is the needle thread category and the looper thread category. Stitch type-401, which is produced by a needle thread and a looper thread, is the most common. On the top, it looks like a lock stitch, but on the underside, it has a double chain effect created by the looper thread.

Because the needle thread is interconnected with two loops of the under thread, the stitches in this class are sometimes referred to as ‘double lock stitches’. There is very little chance of seam pucker here. All threads are supplied in cone packages so there is no risk of running out. This type of stitch is used when sewing elastic, lace, and braid. Jeans and trousers are sewn with stitch type-401.

5. Stitch class-500 (Over edge stitch):

The stitch type in this class is formed with one or more groups of threads. At least one group passes around the edge of the material. This prevents threads from coming out of the fabric. It is common to use one or two needle threads and one or two looper threads to form a narrow band of stitching along the fabric edge. A trimming knife on the machine makes sure the edges are neat before sewing.

This stitch type-504 is composed of two looper threads and a needle thread. Its extensibility is excellent. Its width is 3-5 millimeters. It is used to neaten edges and to create seams in knitted fabrics. This type of stitch can also be used to create decorative knitted edges.

6. Stitch class-600 (Covering chain stitch):

There are generally three groups of threads used to produce this type of stitch. Two groups of threads can be seen on either side of the stitch. The first group of thread is needle thread, the second group is top cover thread, and the third group is bottom cover thread. This class of stitches can be produced with up to nine threads, and stitch type-606 requires four needle threads and five other threads, which is known as flat lock. In knitted fabrics, flat lock stitches are used especially for underwear. They are also used to decorate leisure wears. Type-602 is used to attach laces, braids, and elastics to garments. It is also used for decorative stitches and top stitching.

Conclusion

Studying the different types of stitches in garment manufacturing provides valuable insight into the techniques and applications of stitching in the industry. As we classify and categorize stitches, we gain a systematic understanding of their characteristics, functionality, and suitability for different materials, garment styles, and construction methods. This experiment has given us an insight into different types of sewing stitches and their functions and uses in the garment industry. I would like to express my deep gratitude to our teacher and our instructors. I believe that this experiment will be very helpful to me in the future.