Experiment Name:

Lab Report: Study on yarn passage diagram of pirn winding machine

Introduction:

A pirn package is the package which is placed inside a shuttle in a shuttle loom. Through the eye/slot of the shuttle, the weft yarn is unwound from the pirn package and laid in the shed as the shuttle travels across the width of the shuttle loom. As the yarn on the pirn tapers at one end, the yarn with drawl takes place continuously without being entangled.

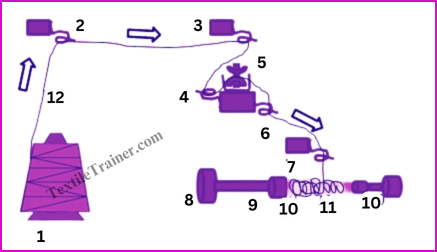

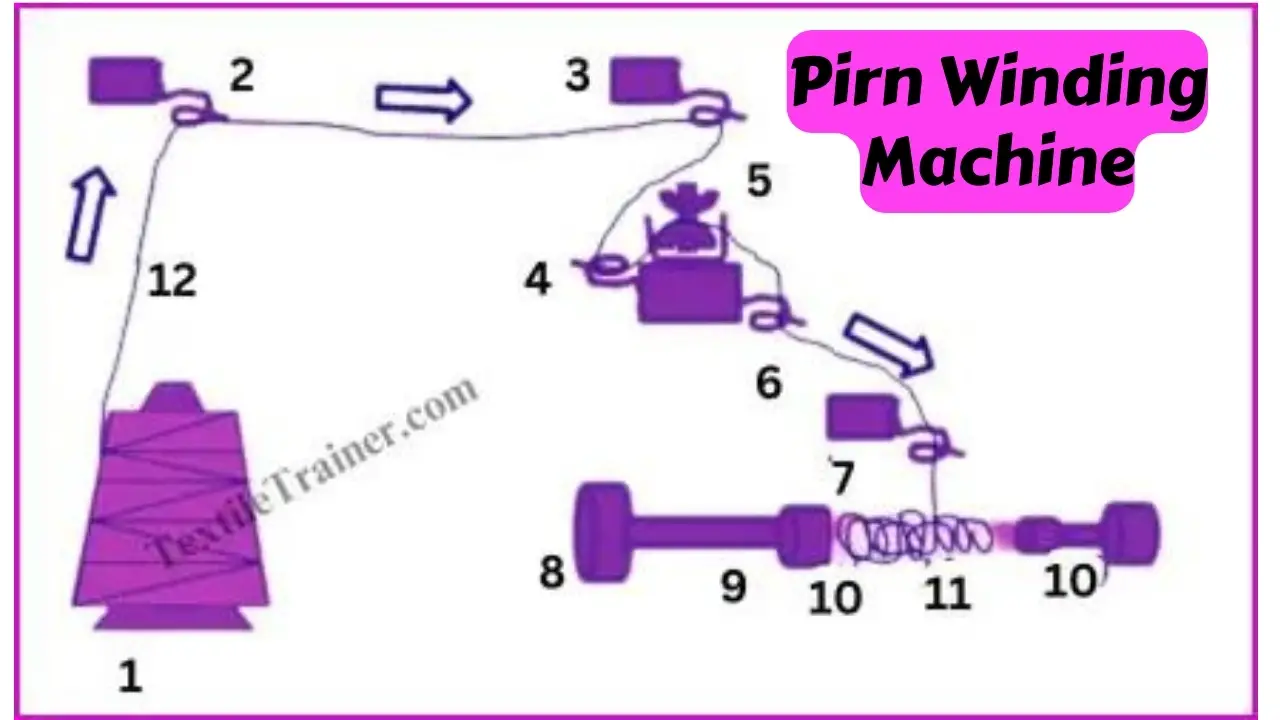

The yarn is transferred from a cone package to a smaller pirn package in the process of pirn winding, shown in figure-1. This process differs from regular winding. As a result of the different geometry of the pirn package, the traverse mechanism is also different here. The traverse does not go back and forth along the package. In order to build yarn on the rest of the pirn package, it must build yarn on one part at a time. With this type of winding, ballooning effects are reduced, uniform tension is maintained, and slough-off is reduced.

Objectives:

- To know about the pirn packages.

- To know the importance of pirn winding.

- To know about the main parts of pirn winding machine.

- To know about the functions of the main parts of pirn winding machine.

- To observe yarn passage path in operation of the pirn winding machine.

- To draw yarn passage diagram of pirn winding machine.

- To make a report on the experimental work.

Apparatus:

- Pirn winding machine,

- Full cone package,

- Empty pirn package etc.

- Scale.

- Pencil.

- Eraser.

Working Procedure:

- At first, run the winding machine very slowly.

- Then observe the yarn passage path sincerely.

- Also observe the all operations of the pirn winding machine carefully.

- Now run the machine with its full speed to see the winding process on pirn.

- Observe the pirn package building process with the help of traverse mechanism.

- Now, be familiar with the main parts of the pirn winding machine with functions.

- Finally, draw a yarn passage diagram of the pirn winding machine.

Diagram of Pirn Winding Machine:

Main Parts of Pirn Winding Machine:

- Motor: Motor is a device which convert electrical energy into mechanical energy.

- Motor Pulley: It is the pulley which is located on the motor shaft and v-belt is placed round the pulley to convey motion of motor pulley to machine pulley.

- Machine Pulley: It is the pulley which is located on the main machine shaft and V-belt is placed round the pulley to receive motion of motor pulley to machine pulley.

- V-Belt: This part conveys the motion from one pulley to another pulley.

- Compound Pulleys: By the help of compound pulleys the v-Belt between machine pulley and wharves can be tighten and loosen as per requirement.

- Wharves: These parts are attached with the spindles directly which rotate the spindles by receiving motion from machine pulley with the help of v-belt.

- Spindle: Pirn packages are placed at the end of the spindles with the help of package holders and pirn packages get rotating motion from spindles.

- Bearing: Bearing helps v-belt being firmly attached with the wharves.

- Package holder: Package holder helps to place the pirn package at the end of spindle directly.

- Traverse guide bar: This bar gives traverse motion to the traverse guides to build pirn packages of near parallel wound.

- Tensioners: Tensioners maintain and ensure the required tension on yarn during winding.

- Yarn guides: These guides control the yarn path.

- Yarn guide bars: Yarn guide bars hold the yarn guides.

- Gears: The different gears help to convey the motion from machine shaft to traversing cam.

- Traversing cam: This cam gives traversing motion to the traverse guide bar.

- Cone package holder: The input yarn is as cone package placed on cone package holder.

Conclusion:

We learned about the diagram of a pirn winding machine from this experiment. We also learned some parts names and their functions in a pirn winding machine. We are grateful to our teachers for their assistance.

You May Read:

- Effective Layout Plan of Fabric Engineering Lab.

- Dynamic Layout Plan of Spinning Lab.

- Bale Breaker Material Passage Diagram: Easy Description.

- Step Cleaner Machine: Simple Working Principle.

- Hopper Feeder Machine in Blow Room with Simple Working Principle.

- Porcupine Opener Machine in Blow Room: Simple Working Principle.

- Scutcher Machine in Blow Room: Feed to Carding Effective Way.

- Material Passage Diagram of Carding Machine with Easy Description.

- Material Passage Diagram of Lap Former Machine.

- Working Principle of Comber Machine: Better Quality Yarn.

- Working Principle of Speed Frame in Ring Spinning with Simple Description.

- Ring Spinning Frame: Working Principle is Describe Very Easy Way.

- Easy Way: Autoconer in spinning working Principle.

- Belt Shifting Mechanism of Speed Frame with Proper Simple Figure.

- Bobbin Building Mechanism of Speed Frame: Easy 3 Step.

2 thoughts on “Yarn Passage Diagram of Pirn Winding Machine is Described Easy Way/Lab Report-02”