Experiment Name:

Lab Report: Study on material passage diagram of hopper feed machine in blow room./ Study on working principle of hopper feeder machine.

Introduction:

The first step in the spinning process is the blow room. Since all the processes in this stage are carried out using air flow, this stage is called the blow room. In a blow room, the hopper feeder helps maintain a steady and controlled flow of material to subsequent machines. It regulates the material flow into downstream processing units. Two hopper feeder machines are included in our blow room section in the laboratory. They are:

- Hopper feeder-I

- Hopper feeder-II

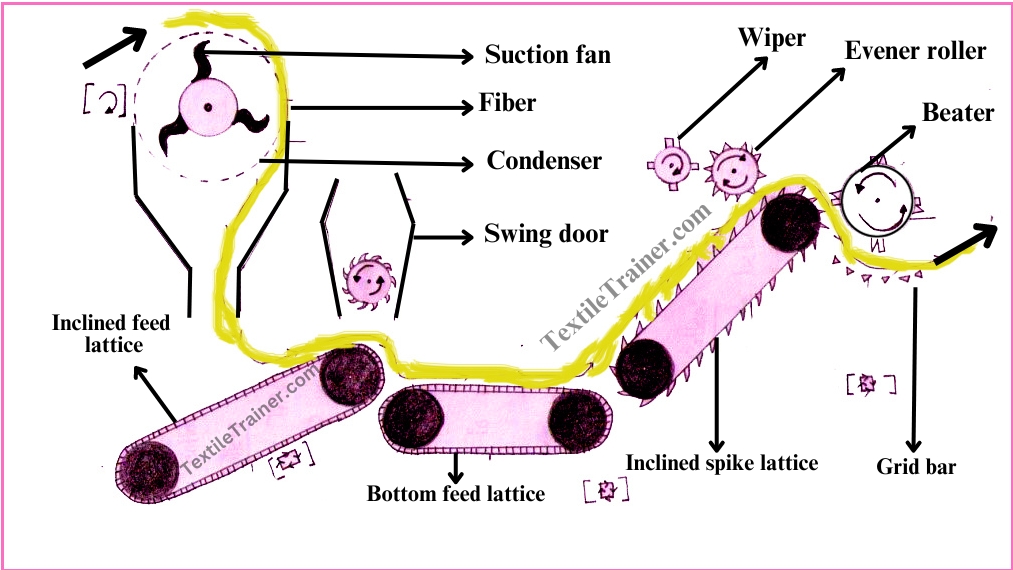

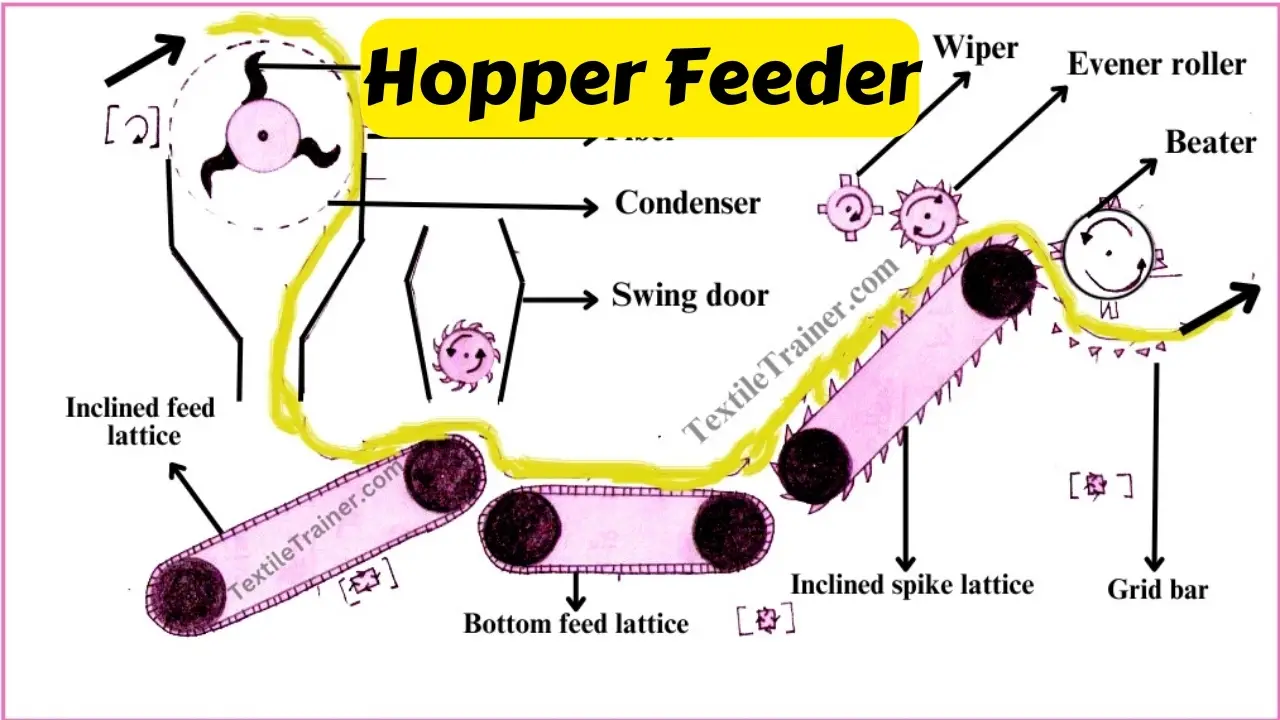

In this machine, the material is thoroughly blended in the mini bin, combed by the inclined spiked lattice, and then the passes between the evener roller and inclined spiked lattice are opened. In this experiment, we will learn different parts and working principle of hopper feeder.

Objectives:

- To know about blow room.

- To know about hopper feeder machine.

- Come to learn main parts of hopper feeder machine.

- To know working principle of hopper feeder machine.

Main Parts of Hopper Feeder Machine:

Hopper feeder machine is used as last second machine in the blow room line. Which is situated before scutcher machine. However, hopper feed machine is consists following parts. They are:

- Feed Lattice: Feed Lattice gives forward motion and carry the bales separated cotton fibers. It is slightly inclined.

- Inclined spike lattice: It gives upward motion and spike separate the balled of cotton.

- Bottom Lattice: Bottom Lattice gives forward motion to carry the cotton I inclined lattice.

- Evener Roller: This roller gives even formation of cotton fibers.

- Wiper roller: In wiping process, it is used for cleaning fibers.

- beater: It is used in beating process.

- Grid: Grid separates clean fibers and impurities.

- Swing door: There are two swing doors as feed limitation and indication.

- Finger or segment roller: It is situated in between two swing doors.

Working Principle of Hopper Feeder Machine:

- Material is fed into the lattice by a slightly inclined feed lattice and moved forward by the bottom lattice.

- The spike on the inclined spike lattice and the upward movement caused the material to move.

- A finger roller is placed between two swing doors. The swing doors control how much cotton bale goes in each direction.

- The inclined spike lattice well combs hard-pressed cotton layers.

- A rotating spike on the evener roller opens the cotton fibers, and a wiper roller keeps the evener roller clean.

- Because there is a small gap between evener roller inclined spike lattice and evener roller rotation in an opposite direction, unopened excess cotton is thrown back into the mixing bin.

- The beater roller strips the cotton fiber and projects it over a grid bar system.

- Finally, the material moves on to the next step.

Conclusion:

In this experiment, we learned about hopper feeder machines. We also learned about parts of these machines and their working principle. These machines are important for opening and cleaning cotton fibers in blow room. This machine helps to improve quality of yarn. We are grateful to our teacher for helping us with this experiment. We will be able to use this knowledge in the future.

You May Read:

- Dynamic Layout Plan of Spinning Lab.

- Bale Breaker Material Passage Diagram: Easy Description.

- Step Cleaner Machine: Simple Working Principle.

- Study on Flow Chart of Trutzschler Blow Room for Cotton Spinning.

- Study on Modern Flow Chart of Rieter Blow room Line with Proper Picture.

- What is Spinning? Different Types of Yarn Spinning is Described in Easy Way.

- Working Principle of Rieter UNIFlex for Unparalleled Production in Blow Room.

Enjoyed every bit of your blog article. Awesome.