Experiment Name:

Lab Report: Study on basic parts of a loom and observation of the basic principles of weaving.

Introduction:

In weaving, two sets of yarn are interlaced at right angles by means of looms. The interlacement is done by means of loom basic parts. Without these parts, weaving would be impossible. In this experiment, we will learn basic principle of weaving and basic parts of loom.

Objectives:

- To be familiar woven fabric manufacturing technology of loom.

- To be familiar with the basic parts and their functions of a loom.

- To sketch the basic principles of weaving.

- To make a report on the experimental work.

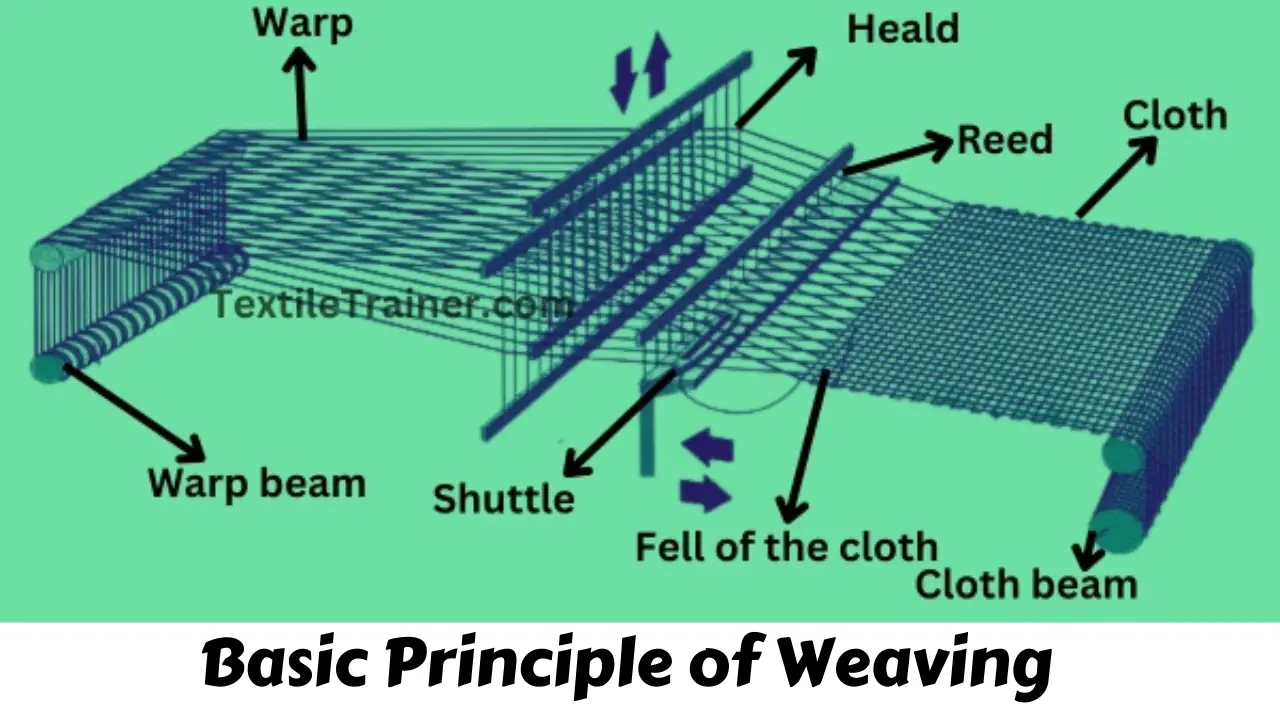

Basic Principle of Weaving:

Fabric weaving involves interlacing the warp and weft according to the design of the fabric. Basic principles of fabric weaving include:

- Weavers beam yarn goes round the backrest and comes forward via the drop wire of the warp stop motion to the heald eye of the heald shaft, which creates shade.

- Afterward, it passes through a dent in the reed that holds the thread in uniform spacing and beats up the weft thread that is found between the two warp sheets and the reed.

- A weft yarn meshes with the last pick of fabric or cloth in this way. In order to make a uniform fabric width, temples hold the cloth firmly at the feeding position. Fabric then passes over the front rest, through the take-up roller, through the pressure roller, and finally onto the cloth roller.

Working Procedure:

- A loom must be carefully observed to understand how it works.

- At first, we run the machine with low speed.

- Understand the basic components and functions of looms

- Sketch the basic principles of the loom with the correct labeling.

Diagram of Basic Principle of Weaving:

Basic Parts of Loom:

- Heald shaft/Harness: A wood or metal frame that keeps the healds or heddles in place on the loom during weaving.

- Shuttle: In order to interlace warp and weft, this vehicle passes through the divided warp.

- Shuttle box: To hold the shuttle between picking motions on a shuttle loom, there is a compartment at each end of the sley.

- Picker: In a shuttle box, it is a piece of leather or metal placed inside grooves or on a spindle.

- Beams: It consists of a cylindrical body with end flanges on which a multiple of warp ends are wound, allowing them to be removed as a warp sheet.

- Front rest: A fixed roller is installed above the cloth beam on the loom and acts as a guide for winding cloth onto the beam.

- Lease rods: Lease refers to the division of warp yarn into one and one, two and two, etc., and the rods passed between the successive divisions are called lease rods.

- Sley: It is the part of the loom that carries the reed and oscillates between the harness and the fell.

- Reed: During weaving, a comb-like wire is used to separate yarns on a loom and to beat up the filling.

- Treadle: Threads are connected by cords to the treadle, which is a paddle or lever under a loom.

- Temple: To prevent the filling from drawing the cloth too much, rollers on a loom hold the cloth at the proper width.

Conclusion:

With this experiment, we learned basic weaving principles with diagram of weaving mechanism. We also learned the main parts of the loom. Thanks to our teacher for helping us with this experiment.

You May Read:

- Effective Layout Plan of Fabric Engineering Lab.

- Yarn Passage Diagram of Pirn Winding Machine is Described Easy Way.

- Dynamic Layout Plan of Spinning Lab.

- Bale Breaker Material Passage Diagram: Easy Description.

- Step Cleaner Machine: Simple Working Principle.

- Hopper Feeder Machine in Blow Room with Simple Working Principle.

- Porcupine Opener Machine in Blow Room: Simple Working Principle.

- Scutcher Machine in Blow Room: Feed to Carding Effective Way.

- Material Passage Diagram of Carding Machine with Easy Description.

- Material Passage Diagram of Lap Former Machine.

- Working Principle of Comber Machine: Better Quality Yarn.

- Working Principle of Speed Frame in Ring Spinning with Simple Description.

- Ring Spinning Frame: Working Principle is Describe Very Easy Way.

- Easy Way: Autoconer in spinning working Principle.

- Belt Shifting Mechanism of Speed Frame with Proper Simple Figure.

4 thoughts on “Basic Principle of Weaving: Very Easy Way”