Experiment Name:

Lab Report/Study on material passage diagram of bale breaker

Introduction:

The bale breaker is the first machine used in cotton spinning mills. Raw cotton bales are delivered in compressed form to cotton spinning mills. These compressed bales need to be opened for cleaning, mixing, and blending. Bale breaking is the main function of the machine. Additionally, it mixed different grades of cotton. A bale opener is made up of several opening and cleaning devices used to process textile fibers, including opening, cleaning, blending, and mixing, before being transported to a subsequent machine for further processing.

Objectives:

- To know about Bale Breaker.

- To know different parts of Bale Breaker Machine.

- Come to learn working principle of Bale Breaker.

Function of Bale Breaker:

The bale opener is a machine used in the textile industry, specifically during the initial stages of processing raw materials like cotton. Its primary function is to open compressed bales of cotton or other fibers, separating and loosening them. Some important function of bale breaker is given below:

- Bale opening: The primary function of bale breaker is opened the compressed bale of cotton. Cotton bales are tightly packaged for easy transportation. Bale breaker break the bale of cotton.

- Trash remove: Cotton fiber contains various impurities and contaminations which is refer as “trash” in spinning mill. Bale breaker remove this trash.

- Fiber separation: Fiber separation is the another important function of bale opener. Bale breaker separate and individualize the fiber from each other.

- Blending and mixing: After open and separation of cotton fiber, bale breaker blending and mixing different types of fiber each other.

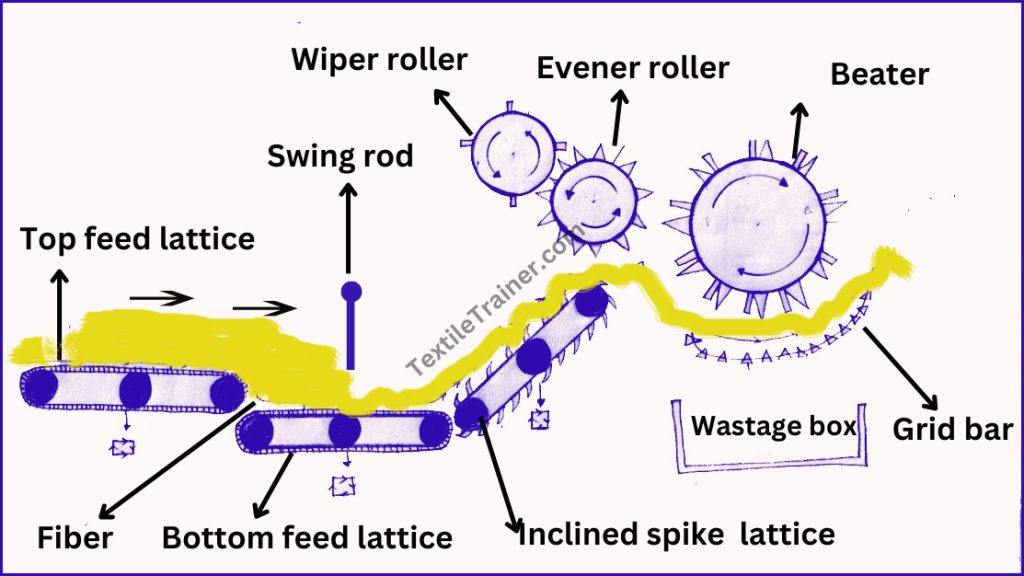

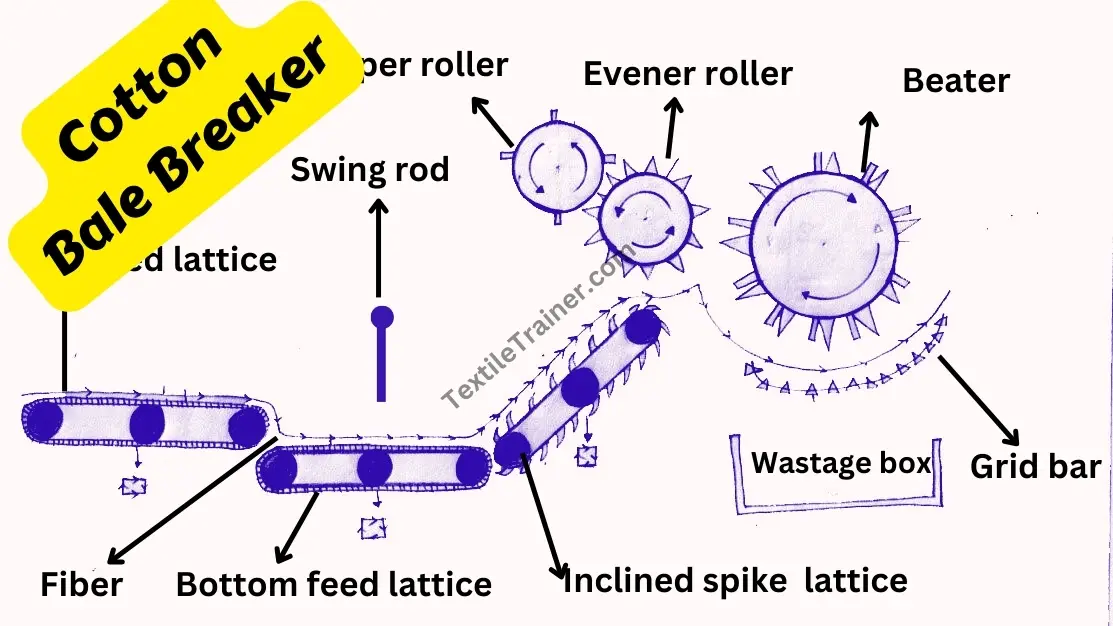

Main Parts of Bale Breaker

- Feed Lattice: Feed lattice gives forward motion and carry the bales separated cotton fibers.

- Bottom lattice: Bottom lattice gives forward motion to carry the cotton till inclined spike lattice.

- Inclined spike lattice: It gives upward motion and spike separate the balled of cotton. It inclined at 450

- Striker: It’s striker the cotton fiber.

- Evener Roller: This roller gives even formation of cotton fibers.

- Wiper Roller: In wiping process, it uses for cleaning cotton fibers.

- Grid: Grid used to separate fiber and impurities.

- Beater: It is used in beating process.

- Delivery pipe: It’s movies the fiber for next machine.

- Swing Rod: There are two Swing rod as feed limitation indicator.

Working Principle of Bale Breaker:

- In the beginning, compact fiber was placed on the feed lattice.

- After this, the tuft was constructed along with a half-sized bottom lattice.

- Two rods were placed at the top of the bottom lattice to ensure uniform feeding and reduce overfeeding.

- An inclined spike lattice was placed at the end of the bottom lattice with 450 angle and six rows of spikes which act as an opening mechanism for the tuft.

- At the side of the roller, a wiper roller with four rubber sheets was placed to remove impurities.

- A beater roller with four rows of pins, rubber sheets, and a triangular grid was used to do the opening of the tuft by beating it up first.

- During process, tufts get lost and impurities of high weight are stored in a waste box below the grid.

- Next, cotton fiber passes through a feed duct into the next machine.

Conclusion:

This machine prepares raw materials for the subsequent processing steps, improves fiber quality, and ensures an efficient and uniform production process in the early stages of textile manufacturing. We learned about bale breaker machines. We also learned about their parts and how they work. This experiment will help us in our future lives. Thanks to our teachers for their assistance.

You May Read:

- Dynamic Layout Plan of Spinning Lab.

- Study on Flow Chart of Trutzschler Blow Room for Cotton Spinning.

- Study on Modern Flow Chart of Rieter Blow room Line with Proper Picture.

- What is Spinning? Different Types of Yarn Spinning is Described in Easy Way.

- Working Principle of Rieter UNIFlex for Unparalleled Production in Blow Room

I really enjoy the blog post.Really looking forward to read more. Really Cool.