Experiment Name:

Lab Report: Study on sequence of combing cycle in combing machine./ Study on combing cycle of comber machine in cotton spinning.

Introduction:

The combing machine, integral in the production of medium, medium-fine, and fine yarns, plays a pivotal role in enhancing various yarn and fabric characteristics. Specifically designed to positively influence evenness, strength, cleanliness, smoothness, visual appearance, and handle, the comber contributes to the production of high-quality textiles. Beyond its impact on yarn characteristics, the comber also proves beneficial in downstream processing, particularly in knitting, by improving working behavior. Notably, yarn derived from combed cotton requires less twist than carded yarn, demonstrating efficiency gains in the manufacturing process. However, these quality improvements come at a cost, involving additional expenditure on machines, floor space, and personnel, accompanied by a loss of raw material. The overall increase in yarn production costs, though, is deemed justifiable given the substantial improvements in yarn and fabric quality. In this experiment, we will learn about combing cycle of combing machine.

A combing cycle is a sequence of operations performed by the combing machine which are repeated throughout one rotation of the index wheel during the course of the cycle.

Objectives:

- To know about combing machine.

- Come to learn combing cycle.

Sequence of Combing Cycle:

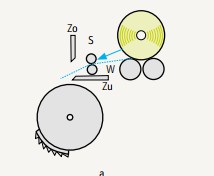

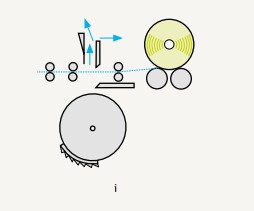

1. Feeding of lap by feed roller :

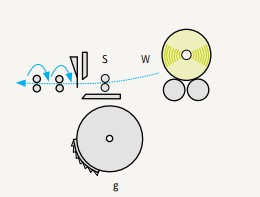

Comber lap is fed into the machine between the feed roller (S) and feed plate. Feed roller moves the lap by 4-6.5 mm.

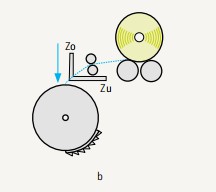

2. Nipping of fibers by nippers :

The top nipper (Zo) moves downward towards the feed plate (Zu). The fibers become clamped between the top and bottom nippers. The cylinder becomes ready for combing.

3. Rotary combing by half circular comb or cylinder comb :

The fibers which are protruding from the lap beyond the nipping point of top and bottom comb are combed by a passage of rows of needles or wires fastened on the surface of cylinder. This cylinder revolves to carry away short fibers, neps and other impurities.

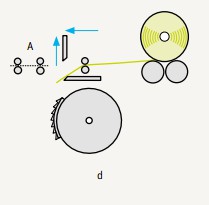

4. Nipper opening and forwarding :

The nippers are opened again. The comber is moved towards the detaching roller (A).

5. Return of web by the reverse rotation of detaching roller :

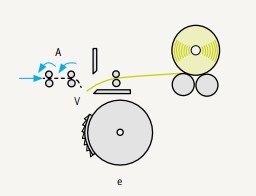

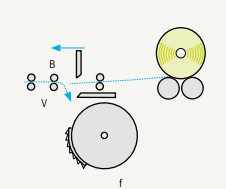

When the nippers gets forwarding motion towards the detaching roller(A) then the detaching rollers return a part of previously drawn web (V) by means of reverse rotation.

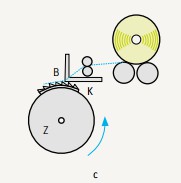

6. Piecing :

Due to the forward movement of nippers towards the detaching roller then the protruding fringe of fiber(B) is placed upon the returned web (V).

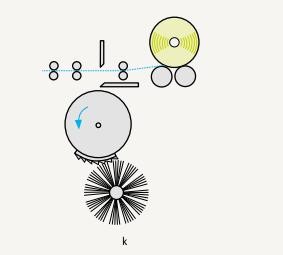

7. Forward movement of detaching roller/detaching :

The detaching rollers draw the clamped fibers out from the lap sheet held between the feed rollers (S) by the forward movement of detaching rollers.

8. Combing by the top comb :

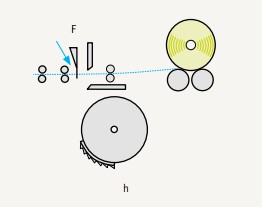

Top comb (F) performs combing operation on the upper side of the fringe. Before starting the detaching operation a top comb having single row of needles is thrusted into the fiber fringe. During detaching operation when the clamped. Fibers are pulled through the needle of top comb (F) then the leading hooks are straightened. This can not be done by cylinder combing.

9. Retraction / backward motion of nipper :

Nippers move back. Top comb is withdrawn and a new combing cycle is started.

10. Waste extraction by brush :

The combing segment and the cylinder comb are cleaned by a brush roller (K).

Conclusion:

As a result of this experiment, we learned about the combing cycle of cotton combing machine. This experiment will be useful to us in our future lives. Thank you to our teacher for helping us.

You May Read:

- Dynamic Layout Plan of Spinning Lab.

- Bale Breaker Material Passage Diagram: Easy Description.

- Step Cleaner Machine: Simple Working Principle.

- Hopper Feeder Machine in Blow Room with Simple Working Principle.

- Porcupine Opener Machine in Blow Room: Simple Working Principle.

- Scutcher Machine in Blow Room: Feed to Carding Effective Way.

- Material Passage Diagram of Carding Machine with Easy Description.

- Material Passage Diagram of Lap Former Machine.

- Working Principle of Comber Machine: Better Quality Yarn.

- Working Principle of Speed Frame in Ring Spinning with Simple Description.

- Ring Spinning Frame: Working Principle is Describe Very Easy Way.

- Easy Way: Autoconer in spinning working Principle.

Really enjoyed this article post.Much thanks again. Much obliged.