Ring Spinning Frame: Working Principle is Describe Very Easy Way

Experiment Name:

Lab Report: Study on working principle of ring spinning frame/ Material passage diagram of ring spinning frame.

Introduction:

This machine uses roving as input material and ring spun as output material. Ring frame machines give materials an idealized twist. The waste is pneumatic. Using a ring frame, cotton fibers such as roving are spun into yarn. The machine stretches and drafts the material. By using the drafting unit, we can reduce the mass of material to produce the desired fineness. It can be used to make yarn in any count.

Objectives:

- To know about ring spinning frame machine.

- Come to learn function of ring spinning frame.

- To know different parts name of these machine.

- To know working principle of ring frame machine.

Function of Ring Spinning Frame:

Given blew major function of these machine

- Creeling: On creel roads, roving hangers hold the roving in a vertical position.

- Drafting: Through draft in which the roving passes through three rollers to attain different speeds, we are able to reduce the weight per unit length.

- Twisting: During the drafting process, the yarn undergoes twist interstation and passes down the spindle assembly where it is passed through the traveller.

- Winding: During spinning, the yarn is rotated on bobbins attached to the spindle, resulting in a balloon.

- Building: By raising and lowering the rings on a continuous ring rail, yarn is wound on a cylindrical cop.

- Doffing: Bobbin doffing is the process of replacing a fully wound bobbin with an empty one.

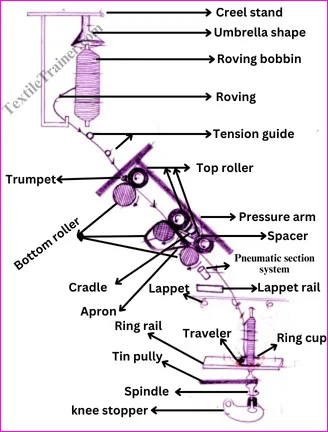

Diagram of Ring Spinning Frame:

Main Parts of Ring Spinning Frame:

Given blow main parts of these machine.

- Creel unit

- Creel stand

- Bobbin holder

- Separator

- Guide bar

- Trumpet

- Travels Bar

- Drafting arrangement

- Trop roller/Cot roller

- Bottom roller (fluted)

- Top and bottom apron

- Pressure arm

- Cradle

- Spacer

- Nose bar

- Pneumatic section system

- Pipe

- Yarn/ Thread guide eyelet/Lappet

- Lappet rail

- Separator

- Spindle

- Spindle belt

- Spindle

- Tin pulley

- Main shaft

- Traveler

- Ring cup

- Ring rail

- Knee break

- Balstar

- Balloon Controller

- Main Motor

Working principle of Ring Spinning Frame:

- The first step in creeling is to fit the roving in the creel with the help of roving holders.

- As the material passes through the 3 over 3 drafting system, it becomes paralyzed, straight and long.

- After that, it is placed on the spindle through rail wire, where it is twisted, wound, and built with help from bobin rails and traveller rails.

- Doffing is done at the end, which means that empty packages are given as input and full packages are taken down as output.

Conclusion:

This experiment teaches us about ring frame machines, which can process a wide range of counts, and that this machine can spin almost any type of material. But it also has some drawbacks. Its production rate is very slow, and it generates a lot of heat while it is working. In spite of its disadvantages, it is very popular when it comes to spinning. It produces very fine yarns.

You May Read:

- Dynamic Layout Plan of Spinning Lab.

- Bale Breaker Material Passage Diagram: Easy Description.

- Step Cleaner Machine: Simple Working Principle.

- Hopper Feeder Machine in Blow Room with Simple Working Principle.

- Porcupine Opener Machine in Blow Room: Simple Working Principle.

- Scutcher Machine in Blow Room: Feed to Carding Effective Way.

- Material Passage Diagram of Carding Machine with Easy Description.

- Material Passage Diagram of Lap Former Machine.

- Working Principle of Comber Machine: Better Quality Yarn.

- Working Principle of Speed Frame in Ring Spinning with Simple Description.

Please share our articles on your social media. You can also publish articles on our website. Feel free to send us your articles by email.