Autoconer in spinning working Principle

Experiment Name:

Lab Report: Study on material passage diagram of autoconer in spinning/ Working principle of automatic cone winding (Autoconer) machine in spinning mill.

Introduction:

In textile industry, spinning is primarily used to make yarn from fiber, and a larger package of yarn is formed at the end with a winding machine. In order to meet all the requirements, the autoconer needs to run efficiently to fulfill all the requirements. A slower cheese & cone forming process (i.e. winding) will ultimately result in loss in production. If we eliminate some responsible causes of low efficiency of the autoconer machine, such issues will not occur. Auto coner is a modern yarn winding machine. It is used to prepare larger packages from ring bobbin cops. It has a winding machine and some extra specifications. Ring cops are used as input and large packages are output from this machine.

Now-a-day Rieter automatic winding machine autoconer X6 is widely used. Various staple fiber yarns can be wound into process-optimized packages using the Autoconer X6 winding machine, which offers maximum productivity, intelligent process automation, and ergonomic operation. In addition to being able to process up to four materials simultaneously, Autoconer X6’s Multilink and Multi-lot options ensure greater flexibility, cost effectiveness, and space efficiency. In this experiment, we learn about rieter autoconer X6 machine.

Objectives:

- To know about Autoconer machine.

- Come to learn main parts of autoconer in spinning.

- To know working principle of autoconer in spinning.

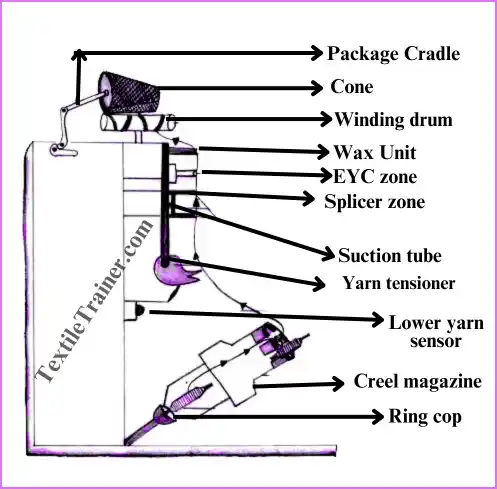

Diagram of Autoconer Machine:

Main Parts of Autoconer in Spinning:

- Creel(Manganize type)

- Chute Guide

- Cop holder/Bobbin holder/Bobbin Peg

- Yarn sensor/Lower yarn Sensor

- Electromagnetic Tensioner

- Sunction Mouth With upper yarn tension.

- Splicer

- Uster Quantum(Sensor):Electronic Yarn Clearer(Eyc)

- Upper Tensioner

- Waxing Unit

- Yarn Trap

- Package cradle

- Winding Drum/Groove Drum

- Lower gripping pipe with shutter/ Retie Pipe

- Bale con/Ballon control

- Tension cutter

Working Principle of Autoconer Machine:

- The machine is driven by a motor on one side, and the motor rotates the cam shafts and drum shafts.

- The yarn supply is obtained from a bobbin, and the yarn is guided to the cone by a yarn stop motion guide and a yarn treasuring guide.

- The cones are attached to the holder and are in contact with the drum; therefore, friction between the drum and holder causes the cone to rotate and ultimately become wound on the yarn cone.

- The yarn guide controls the winding process.

- In the event of yarn breakage, the winding is stopped in a stop motion.

- When the cone reaches a predefined width, it is taken out of the cone to be discrete from the new cone.

Conclusion:

During this experiment, we learned about the autoconer machine, which produces large packages of products and performs conditioning on them. Our knowledge of the modern autoconer material passage diagram enabled us to find out any basic elements of the machine. Although we could not observe the entire material passage when running the machine, but it was a successful experiment.

You May Read:

- Dynamic Layout Plan of Spinning Lab.

- Bale Breaker Material Passage Diagram: Easy Description.

- Step Cleaner Machine: Simple Working Principle.

- Hopper Feeder Machine in Blow Room with Simple Working Principle.

- Porcupine Opener Machine in Blow Room: Simple Working Principle.

- Scutcher Machine in Blow Room: Feed to Carding Effective Way.

- Material Passage Diagram of Carding Machine with Easy Description.

- Material Passage Diagram of Lap Former Machine.

- Working Principle of Comber Machine: Better Quality Yarn.

- Working Principle of Speed Frame in Ring Spinning with Simple Description.

- Ring Spinning Frame: Working Principle is Describe Very Easy Way.

Please share our articles on your social media. You can also publish articles on our website. Feel free to send us your articles by email.