Experiment Name:

Lab report: Study on layout plan of spinning lab

Introduction:

Layout planning is a technique of locating machines based on the product operation in order to ensure the highest possible output with high quality. In other words, Layout planning is determining the best physical arrangement of all resources that consume space within a facility. For a textile factory, a good layout plan is crucial since it will reduce production costs and deliver high quality products to customers. We will learn the layout plan of our spinning lab in this experiment.

Objectives:

- To learn about the yarn laboratory/short staple spinning laboratory.

- Learn about the spinning lab machine

- Obtaining information about different types of machines.

Flow chart of carded yarn manufacturing process:

| Input | Machines | Output |

| Cotton bales | Bale management | Selected cotton bales |

| Selected cotton bales | Blow room | Blow room lap |

| Blow room lap | Carding | Carded sliver |

| Carded sliver | 1st drawing | Drawn sliver |

| Drawn sliver | Finisher drawing | Finisher drawn sliver |

| Finisher drawn sliver | Simplex | Roving |

| Roving | Ring frame | Ring cops |

| Ring cops | Auto coner | Cone package |

Flow chart of combed yarn manufacturing process:

| Input | Machines | Output |

| Cotton bales | Bale management | Selected cotton bales |

| Selected cotton bales | Blow room | Blow room lap |

| Blow room lap | Carding | Carded sliver |

| Carded sliver | 1st drawing | Drawn sliver |

| Drawn sliver | Lap former | Mini lap |

| Mini lap | Comber | Combed sliver |

| Combed sliver | Finisher drawing | Finisher drawn sliver |

| Finisher drawn sliver | Simplex | Roving |

| Roving | Ring frame | Ring cops |

| Ring cops | Auto coner | Cone package |

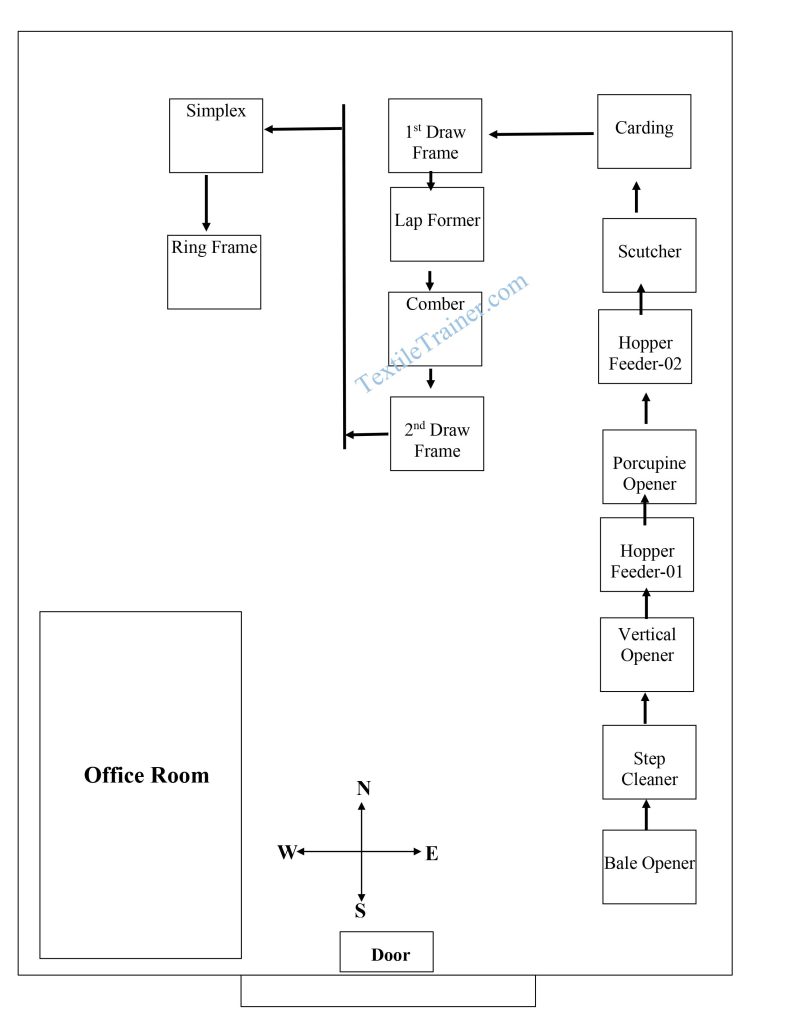

Layout Plan of Spinning Lab:

List of Machine in Cotton Spinning Lab:

1. Blow room:

a). Machine Name: Bale Opener / Breaker.

- Manufacturing Year: 1959

- Model Name: J890

- Brand Name: PLATT Brothers

- Country of origin: England

- Input of machine: Bale

- Output Material: Opened tufts/flocks

Function of Machine:

- In conventional machine, mixing or blending is done by hand.

- In modern machine, mixing or blending is done by machine.

b). Machine Name: Step Cleaner

- Manufacturing Year: 1959

- Model Name: J890

- Brand Name: PLATT Brothers

- Country of origin: England

- Input of machine: Opened tufts/flocks

- Output Material: (40-70) % Clean Fibers

Function of Machine:

- Trash particles are removed from the fibers.

C). Machine Name: Vertical Opener

- Manufacturing Year: 1959

- Model Name: J890

- Brand Name: PLATTS Brothers

- Country of origin: England

- Input of machine: Low grade & short staple cotton

- Output Material: Sorted fibers

Function of Machine:

- It is used to process only low grade and short staple cotton.

d). Machine Name: Hopper Feeder-01

- Manufacturing Year: 1959

- Model Name: J890

- Brand Name: PLATTS Brothers

- Country of origin: England

- Input of machine: open cleaned tufts

- Output Material: Mixed or Blended Tufts

Function of Machine:

- It is used for mixing or blending process.

e). Machine Name: Porcupine Opener

- Manufacturing Year: 1959

- Model Name: J890

- Brand Name: PLATTS Brothers

- Country of origin: England

- Input of machine: – Mixed or Blended Tufts

- Output Material: – Clean Blended Tufts

Function of Machine:

- To open the tufts and reduce the tufts size.

f). Machine Name: Hopper Feeder -02

- Manufacturing Year: 1959

- Model Name: J890

- Brand Name: PLATTS Brothers

- Country of origin: England

- Input of machine: – Clean Blended Tufts

- Output Material: – (70-80%) Clean Blended Tufts

Function of Machine: –

- To open the tufts and reduce the tufts size.

g). Machine Name: Scutcher

- Manufacturing Year: 2005

- Model Name: 3ME

- Brand Name: TRUST ZSCHLER

- Country of origin: GERMANY

- Input of machine: Mixed or Blended Tufts

- Output Material: Blow room Lap/Chute mat

Function of Machine:

- A small percentage of cleaning is done in this step.

2. Machine Name: Carding

- Manufacturing Year: 1959

- Model Name:

- Brand Name: PLATS Brothers

- Country of origin: England

- Input of machine: Blow room Lap/Cute Mat

- Output Material: Card Sliver

Function of Machine:

- It is a mechanical process that separates individual fibers.

- It removes naps, trash, dirt’s, leaf’s, dust, foreign materials etc,

3. Machine Name: 1stdraw Frame / Breaker Draw Frame

- Manufacturing Year: – 2007

- Model Name: – RSB-D 27

- Brand Name: RIETER

- Country of origin: Switzerland

- Input of machine: Card sliver

- Output Material: 1stdraw Sliver / Breaker Draw Sliver

Function of Machine:

- Improves eye mess of the sliver & uniformity of fiber, in the sliver.

- Straighten the crimped & hooked fiber.

- Orients the sliver and mix or blend the fibers.

4. Machine Name: Lap Former

- Manufacturing Year: – 2007

- Model Name: – E-26

- Brand Name: – RIETER

- Country of origin: – Switzerland

- Input of machine: 1stdraw Sliver / Breaker Draw Sliver

- Output Material: Mini Lap/Combed Lap

Function of Machine: –

- Mixing and drafting of cotton fiber.

- Making mini lap for comber machine.

5. Machine Name: Comber

- Manufacturing Year: – 2007

- Model Name: LK-20

- Brand Name: LAKSHMI

- Country of origin: INDIA

- Input of machine: Mini Lap

- Output Material: Combed Sliver

Function of Machine:

- Separates the short fibers from the mini lap and provide combed sliver.

6.Machine Name: 2ndDraw Frame/Finisher Draw Frame.

- Manufacturing Year: –

- Model Name: RSB-D 27

- Brand Name: – RIETER

- Input material: Combed Sliver (For combed yarn) Breaker Draw sliver (for combed yarn).

- Output Material: 2ndDrawn Sliver/Finisher Drawn Sliver.

Function of Machine:

- To parallel the fibers in the sliver.

- To reduce weight per unit length etc.

7. Machine Name: Simplex/Roving Frame/Speed Frame.

- Manufacturing Year: 1959

- Model Name: LFS 1660 (LAKSHMI)

- Brand Name: LAKSHMI/PLATS Brothers (Modern Machine)

- Country of origin: ENGLAND

- Input of machine: 2ndDrawn Sliver/Finisher Drawn Sliver.

- Output Material: Roving

Function of Machine:

- Increases strength and cohesiveness.

8. Machine Name: Ring Frame

- Manufacturing Year: 1960

- Model Name: J890/BT

- Brand Name: PLATS Brothers (Modern Machine)

- Country of origin: ENGLAND

- Input of machine: Roving

- Output Material: Ring cops (Carded/ Combed yarn)

Function of Machine:

- The twisted roving is wound on the bobbin which is used in the ‘Ring Frame’ for manufacturing yarn.

Conclusion:

In this experiment, we learned how to plan the layout of our spinning lab. Our teacher helped us to do this experiment. We learned what the machine names are for blow room lines, specifications of the machine, functions, inputs and outputs, and what materials are used in the machine. This experiment will help us in our future.

17 thoughts on “Dynamic Layout Plan of Spinning Lab/ Yarn Manufacturing Experiment No-01”