Experiment Name:

Lab Report: Study on material passage diagram of jute spreader machine in jute spinning.

Introduction:

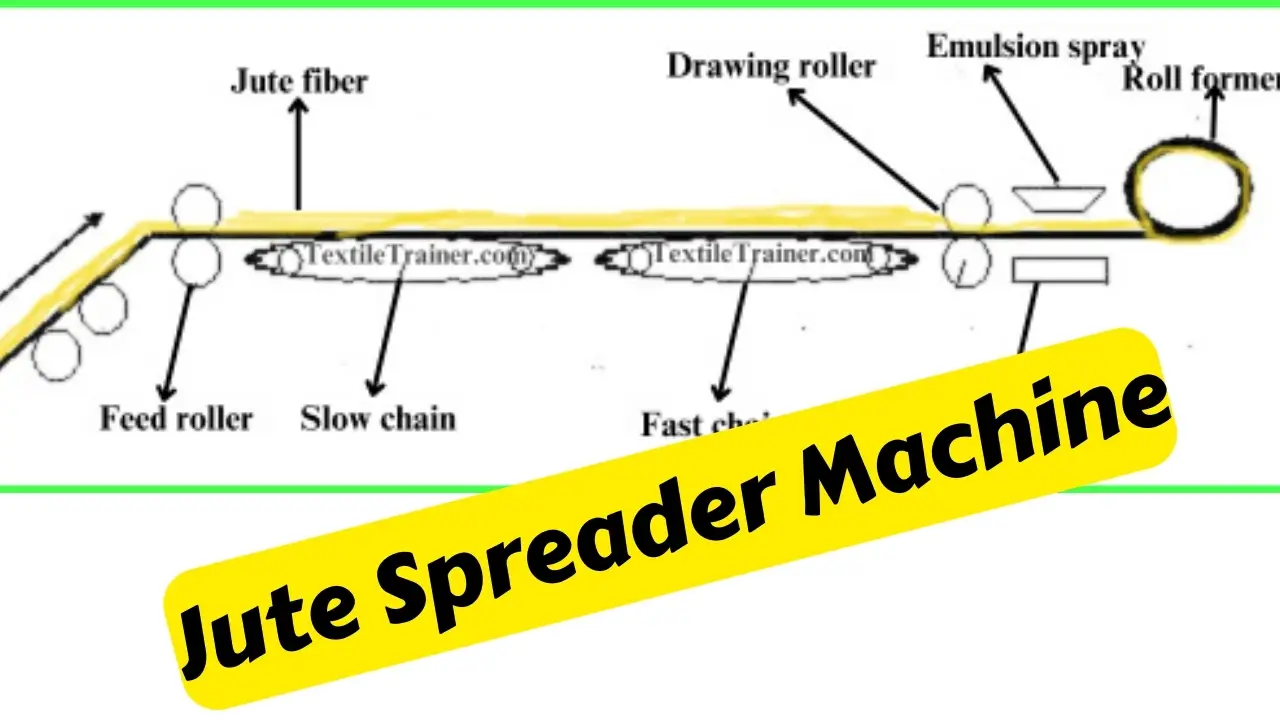

A jute spreader machine is used to comb and open the pieced out of long reeds of jute. This is accomplished by combing the jute. To prepare a ribbon-like sliver, a jute spreader machine is used to convert them into an even and continuous sliver, which receives an even batching emulsion application. After entering the feed rollers, the jute fibers are transferred to the slow chain where pins or grill bars are used to combine the fibers. As a result of the speed variations, jute fibers get a draft of 10 because the fast chain moves 10 to 12 times faster than the slow chain. The jute is then sprayed with emulsion on the conductor plate and rolled up with a roll former.

Objectives:

- To know about jute spreader machine.

- To know different parts of jute spreader machine.

- Come to learn working principle of jute spreader.

Main Parts of Jute Spreader Machine:

- Lead roller;

- Fluted feed;

- Feed sheet;

- Lantern roller;

- Gill bed;

- Conduction plate & emulsion tray.

- Roll forms.

- Fast & slow chain.

Working Principle of Jute Spreader Machine:

- In this machine, there are two sections: a slow chain and a fast chain. Jute is fed manually onto a feed lattice, which is controlled via slave points.

- Using machine feed rollers, the material enters the slow section after feeding the fast section.

- In the slow section, fibers are carried over a gill bed that contains 32 gill bars that is moved slowly by three lantern rollers.

- Afterwards, the material goes to the fast section or combing section, which is formed by a gill bed that moves 10-12 times faster than the slow section.

- Jute is applied to the conductor plate while emulsion is applied.

- The emulsion jute is received in roll form by a roller former.

Conclusion:

A jute spreader machine plays an important role in the processing of jute fibers by opening and combing the pieced-out fibers, contributing significantly to the development of good fibers. As a result of this experiment, we learned how the jute spreader machine works. Thank you to our teacher for helping us. This experiment will be useful to us in the future.

You May Read:

- Jute Softener Machine: Easy Way Material Passage Diagram

- Dynamic Layout Plan of Spinning Lab.

- Bale Breaker Material Passage Diagram: Easy Description.

- Step Cleaner Machine: Simple Working Principle.

- Hopper Feeder Machine in Blow Room with Simple Working Principle.

- Porcupine Opener Machine in Blow Room: Simple Working Principle.

- Scutcher Machine in Blow Room: Feed to Carding Effective Way.

- Material Passage Diagram of Carding Machine with Easy Description

- Study on Flow Chart of Trutzschler Blow Room for Cotton Spinning.

- Study on Modern Flow Chart of Rieter Blow room Line with Proper Picture.

- What is Spinning? Different Types of Yarn Spinning is Described in Easy Way.

Reference:

- Hossain, M. S. (2014). Introduction to Textile Engineering. Dhaka: Books Fair Publications.

- Kadolph, S. J. (2009). Textiles. New Delhi: Dorling Kindersley.

- Siddique, D. H. (n.d.). Natural Fibers. Dhaka.

2 thoughts on “Easy Working Principle of Jute Spreader Machine/ Lab Report-10”