Experiment Name:

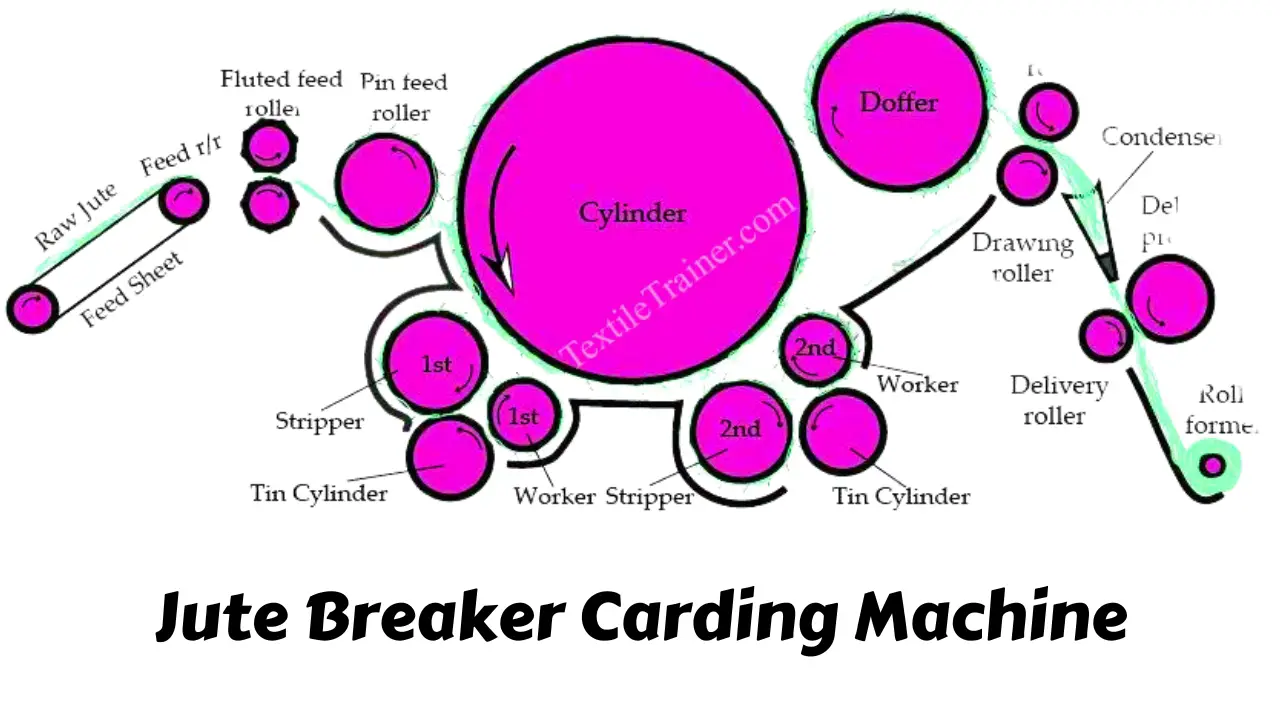

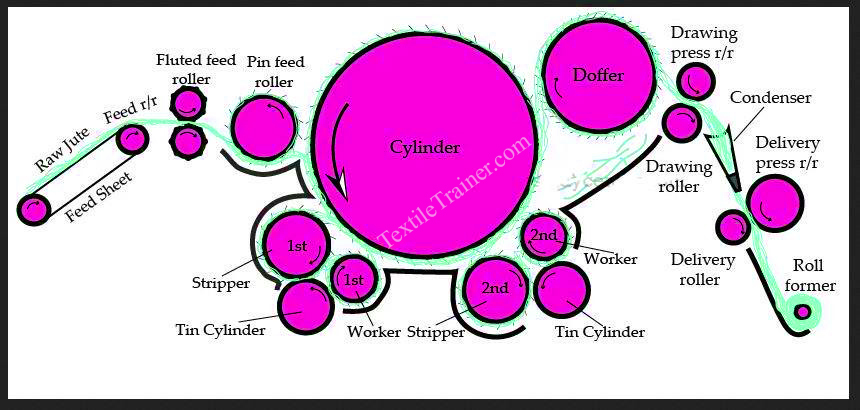

Lab Report: Study on material passage diagram of jute breaker carding machine in jute spinning.

Introduction:

After the fiber from the softening machine has been conditioned for the desired time, it is ready for one of the most important processes in the cycle of jute manufacture, which is carding. A ribbon of jute fibers is formed by converting long strands of jute into a continuous ribbon. The ribbon is known as sliver. Different types of jute in the batch are also blended, and much shorter fibers are removed from the batch as well. Material piled for more than 24 hours is used in hand feed breakers, whereas material piled for 12 hours is used in roll feed carding. After pilling, softened jute is fed into this machine by hand. With the help of different rollers, the machine produces raw jute slivers for the finisher carding machine. There are usually two workers and strippers on breaker cards, and they are usually half circular and down striking. The material is fed to the hand-feed breaker carding machine after root cutting has been completed.

Objectives:

- To know about jute carding machine.

- Come to learn main parts of jute carding machine.

- To know working principle of jute carding machine.

In addition to being long, soft, shiny, and hard, jute has a diameter of 17 to 20 microns and a length of 1 to 4 meters. Considering that jute fiber is long and hard, carding is done on it to produce long continuous jute fibers from the general stage to keep them nearby and separate. There are a number of objectives that can be achieved with jute carding machines. For example:

- Straightening and parallelizing the fiber.

- It is used to remove darts, leaves, broken parts, and very small fibers.

- Carding the different types of jute and blending them together.

- Separately paralyze the fibers.

Working Principle of Jute Breaker Carding Machine:

- From a creel at floor level, six to eight spreader slivers are fed onto the feed sheet, moving towards the breaker card feed roller.

- Jute enters the machine through the shell feed, which consists of a cast iron shell and a pin feed roller. The jute passes between the shell and pin feed roller, making its way towards the pins of the main cylinder.

- When the feeding ends of the reeds intersect with these fast-moving pins, the jute undergoes a transformation: the fibers split, open out, and become fibrous beards.

- When the jute fibers meet the slower-moving workers, they create a carding action with the cylinder, albeit without stripping.

- During the process, the worker’s back-pointing pins oppose the cylinder pins, catching loose fibers point against point while simultaneously opening out and carding them.

- Fibrous material stripped by workers is carried along with them and eventually stripped by the faster-running stripper roller. The resulting waste is discharged through the tin cylinder.

- Therefore, the jute is processed through the first and second pairs of workers and strippers.

- As the fleece of fibers leaves the second worker-stripper pair, it comes into contact with a doffer, which strips the jute from the cylinder.

- A V-shaped condenser is then used to condense the fibers after they pass through the drawing roller.

- Finally, the fibers are delivered to the delivery roller and delivery processing roller, resulting in a rolled sliver.

Conclusion:

This experiment introduces us to material passage diagrams of the breaker card, one of the most important machines of the jute industry. These diagrams will be useful for our future. Thanks our teacher for help us.

You May Read:

- Jute Softener Machine: Easy Way Material Passage Diagram.

- Easy Working Principle of Jute Spreader Machine

- Dynamic Layout Plan of Spinning Lab.

- Bale Breaker Material Passage Diagram: Easy Description.

- Step Cleaner Machine: Simple Working Principle.

- Hopper Feeder Machine in Blow Room with Simple Working Principle.

- Porcupine Opener Machine in Blow Room: Simple Working Principle.

- Scutcher Machine in Blow Room: Feed to Carding Effective Way.

- Material Passage Diagram of Carding Machine with Easy Description

- Study on Flow Chart of Trutzschler Blow Room for Cotton Spinning.