Scutcher Machine in Blow Room: Feed to Carding Effective Way

Experiment Name:

Lab Report: Study on material passage diagram of scutcher machine in blow room

Introduction:

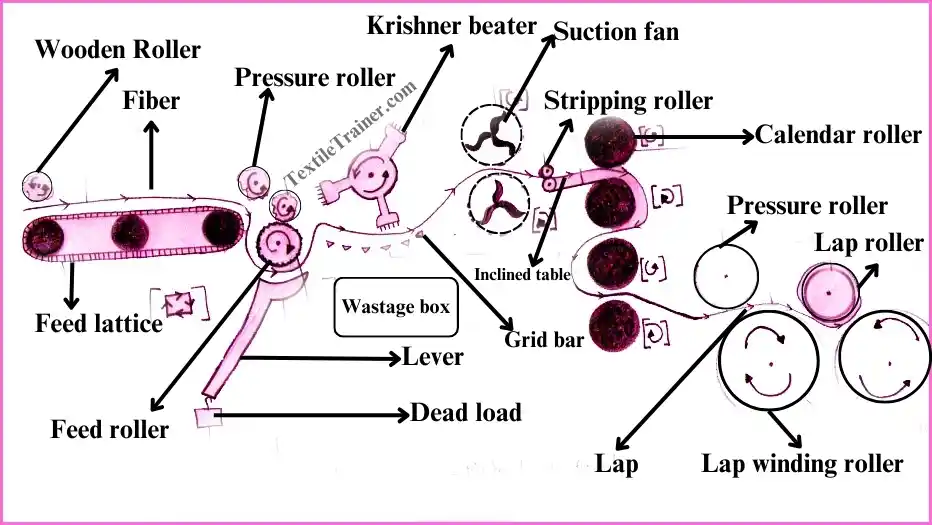

The scutcher machine is the last machine in the blow room. In the cotton blow room, the scutcher machine feeds cotton fiber sheets to the carding machine uniformly. It also aligns the fibers in a parallel orientation in the cotton blow room. In this machine, cotton tufts are further broken down and cleaned by a beater. The mass of cotton is converted into a uniform thick sheet by a beater. The objective of this experiment is to learn about the working principle of a scutcher machine.

Objectives:

- To know about scutcher machine.

- Come to learn main parts of scutcher .

- To know working principle of scutcher machine.

Function of Scutcher Machine:

To further break down and clean the cotton tuft, the Scutcher Machine is used by a beater. It is a machine that converts the mass of cotton into a thick, uniform sheet of cotton. This sheet is called lap This lap feeds to the carding machine. It is the last machine in the blow room section. It is responsible for uniform feeding of the carding machine.

Main Parts of Scutcher Machine:

- Feed lattice: Feed lattice is used for feeding purpose.

- Transport Roller: These rollers transport the cotton fiber.

- Pressure Roller:It applies pressure on the fiber.

- Feed Roller: Feed the fiber into the Kirschner roller.

- Kirschner roller: This beater applies beating mechanism.

- Condenser: There are two condensers in this machine. Fibers are condensed in perforated case.

- Stripping Roller: Stripping is done here.

- Calendar: Four calendaring rollers apply calendaring mechanism for three times.

- Delivery Roller:Output is got by these two-delivery roller.

- Lap Pin: Lap formation of cotton fibers are found in lap pin.

Working Principle of Scutcher Machine:

- A uniform feed lattice is provided across the full width of the scutcher to ensure uniform feeding of cotton.

- Cotton feed is controlled by pedal feed so that the weight of cotton feed per unit time remains constant.

- Cotton is cleaned with a Kirschner beater with three blades.

- It consists of a cage with a fan that suctions impurities to the cage. The material is sucked from bladed beaters and the lighter impurities are extracted from the cage.

- The sheet of paper delivered from the cage is compressed by the calendar roller.

- A compressed cotton sheet is rolled under a pressure roller and the cotton fibers are wound around a lap pin.

Conclusion:

In the last lab, we learned about scutcher machines . Thanks to our teacher for helping us to understand the main parts and working principles of these machines. These machines were essential for lap production. However, this experiment will serve us well in the future.

You May Read:

- Dynamic Layout Plan of Spinning Lab.

- Bale Breaker Material Passage Diagram: Easy Description.

- Step Cleaner Machine: Simple Working Principle.

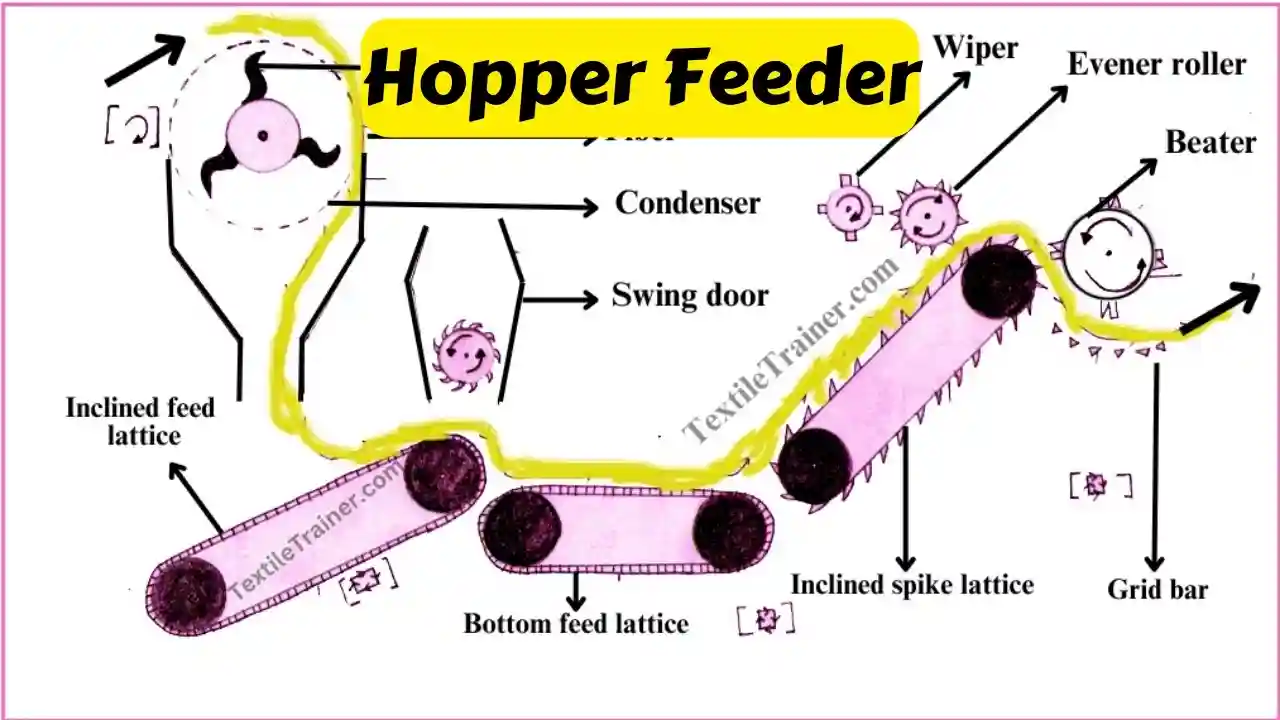

- Hopper Feeder Machine in Blow Room with Simple Working Principle.

- Porcupine Opener Machine in Blow Room: Simple Working Principle

- Study on Flow Chart of Trutzschler Blow Room for Cotton Spinning.

- Study on Modern Flow Chart of Rieter Blow room Line with Proper Picture.

- What is Spinning? Different Types of Yarn Spinning is Described in Easy Way.

- Working Principle of Rieter UNIFlex for Unparalleled Production in Blow Room.

References:

- Belal, P. D. (2009). Understanding Textiles for a Merchandiser . Dhaka: L. B Graphics and Printing.

- Chowdhury, M. F. (2016). Manual of Short Staple Spinning. Dhaka: Granthanir Prokashoni.

- Hossain, M. S. (2014). Introduction to Textile Engineering. Dhka: Books Fair Publications.

- Kadolph, S. J. (2006). Textiles. New Delhi: Dorling Kindersley India Pvt. Ltd.

- Klein, W. (2016). The Rieter Manual of Spinng, Volume-II. Wintherthur: Rieter Machine Works Ltd.