Experiment Name:

Lab Report: Study on working principle of step cleaner machine or ultra cleaner machine in blow room./ Study on material passage diagram of step cleaner machine or ultra cleaner machine in blow room.

Introduction:

After the bale breaker has broken the cotton bale, a step cleaner machine is used to clean the cotton. A step cleaner is used in the textile industry to open and clean a blow room using opposite spikes; it removes heavy impurities and produces smaller cotton. The step cleaner machine is an essential machine in the spinning industry, especially in the blow room section. Step cleaner machine is also called ultra cleaner or supper cleaner machine. It opens up the cotton tuft and cleans impurities from it. As a part of this experiment, we will learn about the working principle of a step cleaner machine.

Objectives:

- To know about step cleaner machine

- To know function of step cleaner .

- Come to learn working principle of step cleaner.

Function of Step Cleaner Machine:

- The primary function of the step cleaner machine is to open and clean the raw cotton fibers.

- Step cleaner also removes various impurities present in the raw cotton fiber.

- Step cleaner machine handle the cotton fibers gently with damage of fiber.

- This machine helps to achieve a more uniform and consistent blend of fiber.

- This machine contributes to the overall efficiency of the next process by effectively opening and cleaning the cotton fiber.

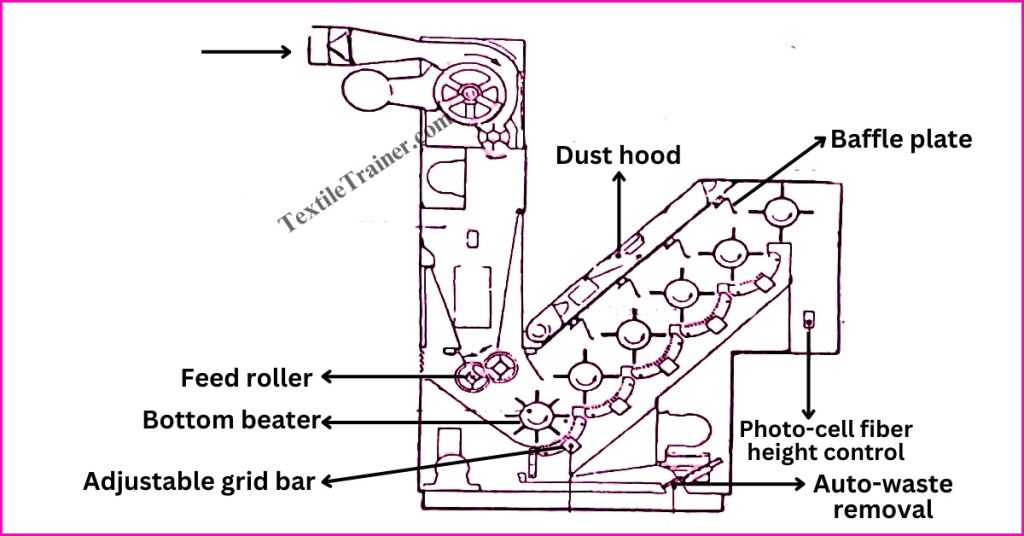

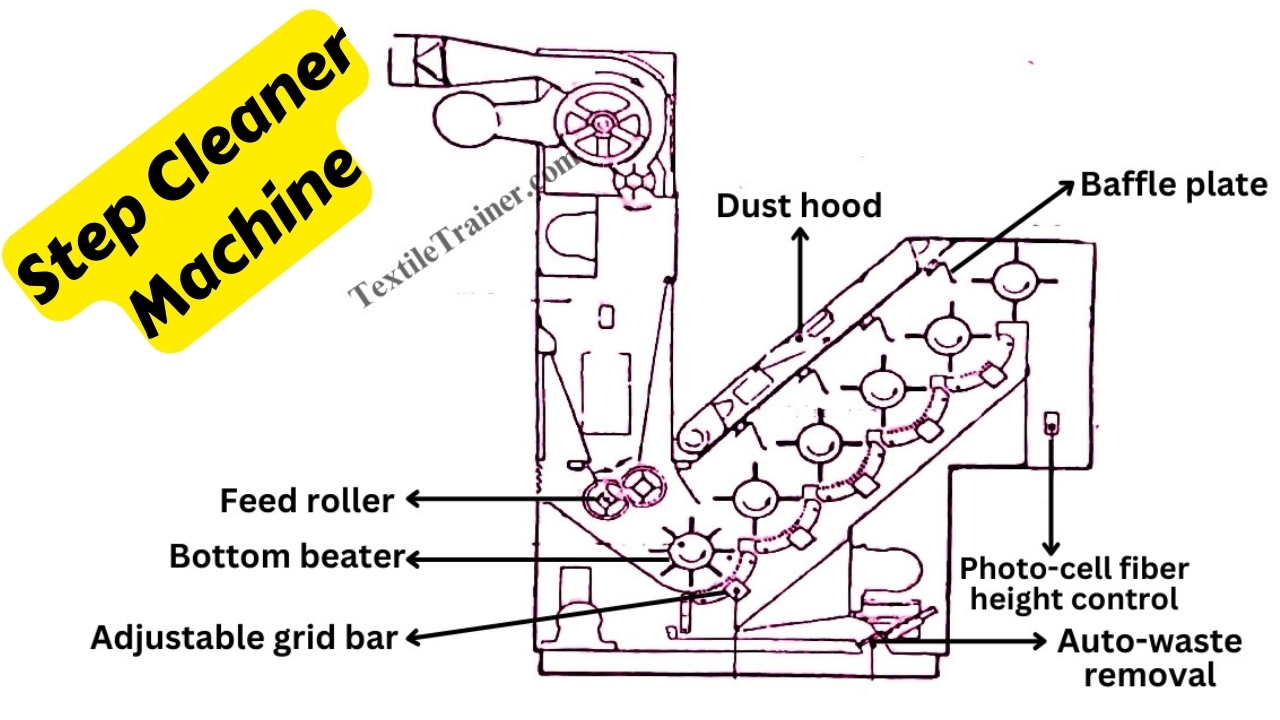

Main Parts of Step Cleaner Machine:

- Feed trunk: Feed trunk is used for feeding purpose.

- Beater + Striker: used for beating fibers. There are 6 beater rollers. Each beater roller has 4 row spike and each spike has 6&7 Striker. There is 156 Striker in beater.

- Baffle plate: Baffle plate increase cleaning intensity.

- Grid & Grid bar: Grid separates impurities and fibers.

- Photo-cell fiber height control: This device control fiber height and ensure uniform delivery of fiber.

- Auto-waste removal: This device remove waste automatic from dust box.

- Delivery trunk: Here, output is delivered. That means, all fiber are deliver via delivery trunk.

Working Principle of Step Cleaner Machine:

- Firstly, the tuft was cleaned and opened, and then the feed trunk was used to input the tuft into the step cleaner machine.

- Afterwards, the material passes through the first beater roller, which is opened and cleaned using spikes, and then it passes through the second beater roller, which is why this machine process involves six beaters.

- A step cleaner opens and cleans step by step on beater rollers, which is why it is called a step cleaner.

- At the time of cleaning and opening, waste is produced, which is removed by a triangular grid situated just below each beater roller.

- Six beater rollers have four columns of strikers and each roller has 26 spikes. Five baffle plates maintain air flow and increase cleaning intensity.

- Impurities goes to the wastage box.

Conclusion:

In the experiment, we learn about the step cleaner machine of blow-room line, where we learn and see their main parts and their working principle. As we observed the machines, we encountered some obstacles. These obstacles should be overcome in the future to ensure lab work. Thank you to our teacher for your support. This experiment will help in our future life.

You May Read:

- Dynamic Layout Plan of Spinning Lab.

- Bale Breaker Material Passage Diagram: Easy Description.

- Study on Flow Chart of Trutzschler Blow Room for Cotton Spinning.

- Study on Modern Flow Chart of Rieter Blow room Line with Proper Picture.

- What is Spinning? Different Types of Yarn Spinning is Described in Easy Way.

- Working Principle of Rieter UNIFlex for Unparalleled Production in Blow Room.

6 thoughts on “Step Cleaner Machine: Simple Working Principle/Lab Report-03”