Experiment Name:

Lab Report: Study on construction of tappet for plain weave.

Introduction:

In general, tappets are used for shedding heald. A tappet, cam, or wiper are all irregular pieces of machinery that are given a rotary motion for the purpose of producing reciprocating motion in rods and levers by sliding contact. In general, a tappet is used when a rod is to be lifted successively with intervals of rest.

Objectives:

- To know the construction of tappet shedding mechanism.

- To identify the different parts shaped this shedding.

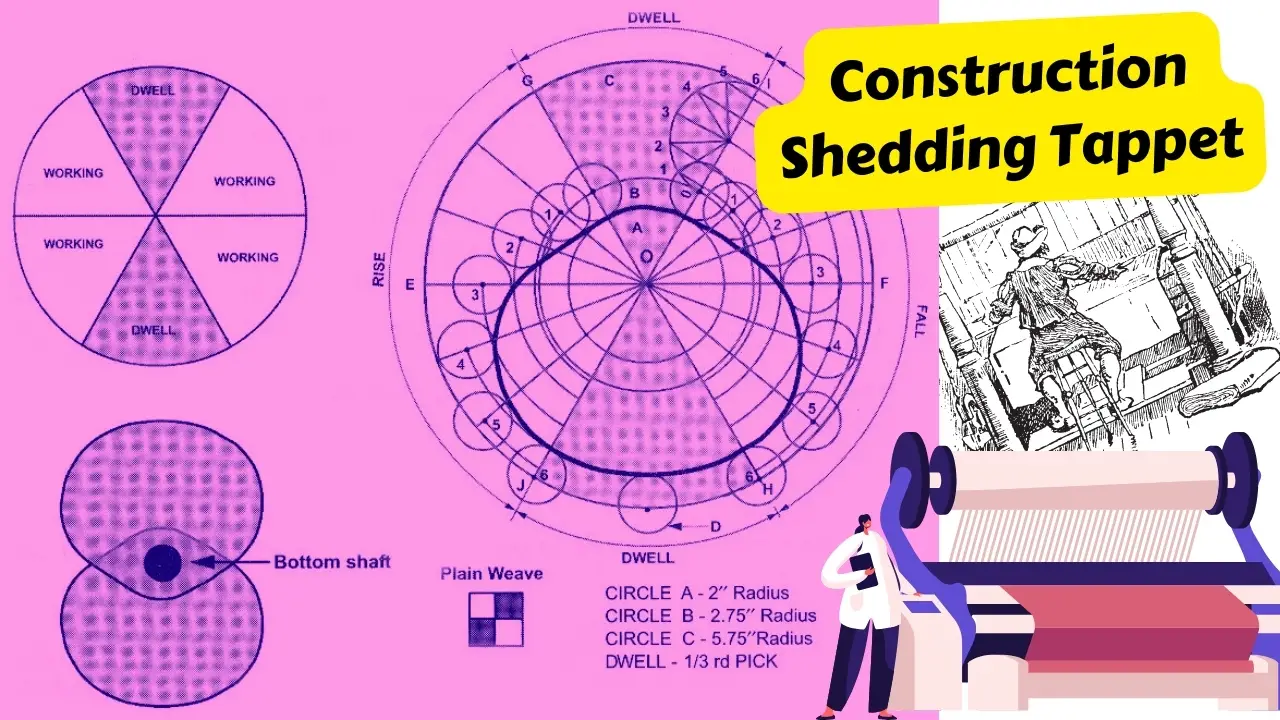

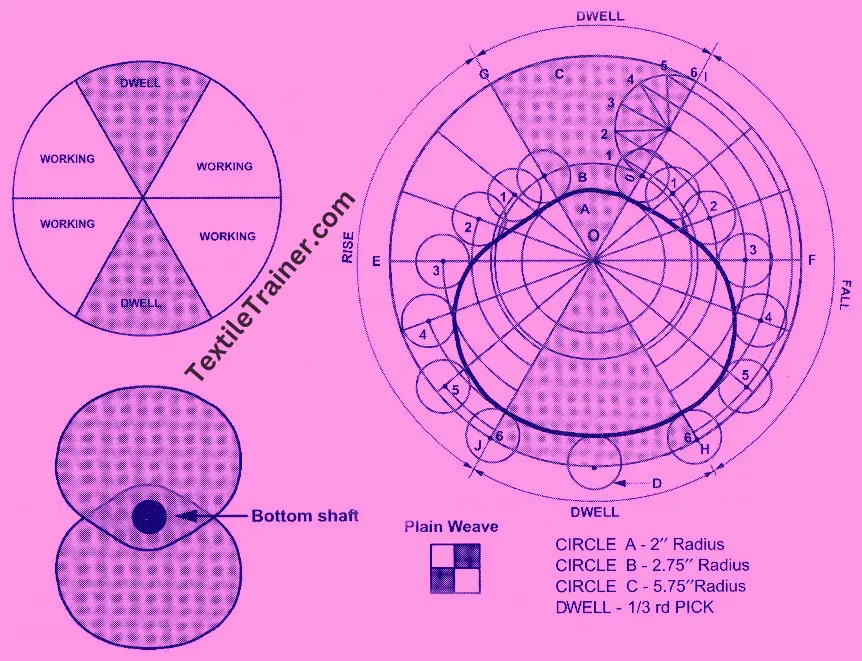

Construction of Tappet for Plain Weave:

The following factors have been considered when designing a shedding tappet for plain weave:-

- Lift of tappet= 4 cm

- Distance from the center of the driving shaft to the nearest point of contact, with the treadle bowl = 2 cm

- Dwell of tappet = one third of a pick

- Diameter of treadle bowl= 2 cm.

Working Procedure:

- Draw a circle A of radius 2cm with O as centre as in Figure. This radius is taken as it represents the nearest point of contact of the bottom shaft with the bowl.

- Draw a circle B of radius 3cm with O as centre. The additional 1cm accounts for the radius of the bowl.

- Draw a circle C of radius 7cm with O as centre. 4cm are added for the lift of tappet.

- Draw a line EF to divide the circle into two equal parts to represent two picks.

- Divide each semi-circle into three equal parts by drawing lines GH and IJ. In the upper half circle EOG and FOI represent working parts and GOI represents the dwell part (1200 of crank shaft) for the first pick. In the lower half circle EOJ and FOH represent working parts and JOH represents the dwell part (1200 of crank shaft) for the second pick.

- Divide sectors GOJ and IOH into six equal parts, as shown in the figure.

- Draw a semicircle on OI between circles B and circle C, as shown.

- Divide the semicircle into six 300 sectors. Draw perpendicular lines from each sector up to the base of the semicircle and name the ends as 0 to 6.

- Draw arcs from the base of each perpendicular line i.e. from 1 to 5 of the semi circle to intersect the dividing lines of the working parts. This is to represent the different positions of the bowl of D at the time of rising and falling movements.

- Each point of intersection is taken as centre and the positions of the bowl are drawn as circles. This is repeated for all the working areas.

- Now, draw the positions of the bowl in the dwell parts also.

- Then, draw a free hand curve touching all the anti-friction bowls tangentially. This gives the profile of the plain weave tappet.

- Two tappets of similar type are assembled and shown in the figure.

- The weave shown represents plain or 1/1 weave.

Conclusion:

Through this experiment, we learned about shedding tappets, as well as how tappet are constructed. This experiment helped us in our future lives. Thank you to our teacher for helping us out.

You May Read:

- Effective Layout Plan of Fabric Engineering Lab.

- Basic Principle of Weaving: Very Easy Way.

- Yarn Passage Diagram of Pirn Winding Machine is Described Easy Way.

- Yarn Passage Diagram of Circular Knitting Machine.

- Yarn Path Diagram of Power loom with Basic parts.

- Negative Tappet Shedding Mechanism with Simple Gearing System.

- Dynamic Layout Plan of Spinning Lab.

- Bale Breaker Material Passage Diagram: Easy Description.

- Step Cleaner Machine: Simple Working Principle.

- Hopper Feeder Machine in Blow Room with Simple Working Principle.

- Porcupine Opener Machine in Blow Room: Simple Working Principle.