Experiment Name:

Lab Report: Study on layout plan of fabric engineering lab.

Introduction:

Plant layout refers a systematic and efficient functional arrangement of various machines, equipment, tools, furniture etc. in such a manner so as to have quickest flow of material at the lowest cost and with the least amount of handling in processing the product from the receipt of raw material to the delivery of the final product.

Objectives:

- To know about the overall idea of a layout plan of fabric manufacturing laboratory.

- To know about the specifications of the machines of fabric manufacturing laboratory..

- To know about the arrangement of machine in weaving and knitting floor.

- To know about the production sequence of weaving and knitting floor.

- To make a report on the experimental work.

Apparatus:

- Pencil.

- Measuring Tape.

- Scale etc.

Working Procedure:

- First, observe the machinery used in fabric manufacturing.

- After that, we note down the machine specifications.

- Carefully measure the dimensions of the laboratory, the machineries, and other furniture in the lab.

- Finally, draw a neat layout plan for our lab.

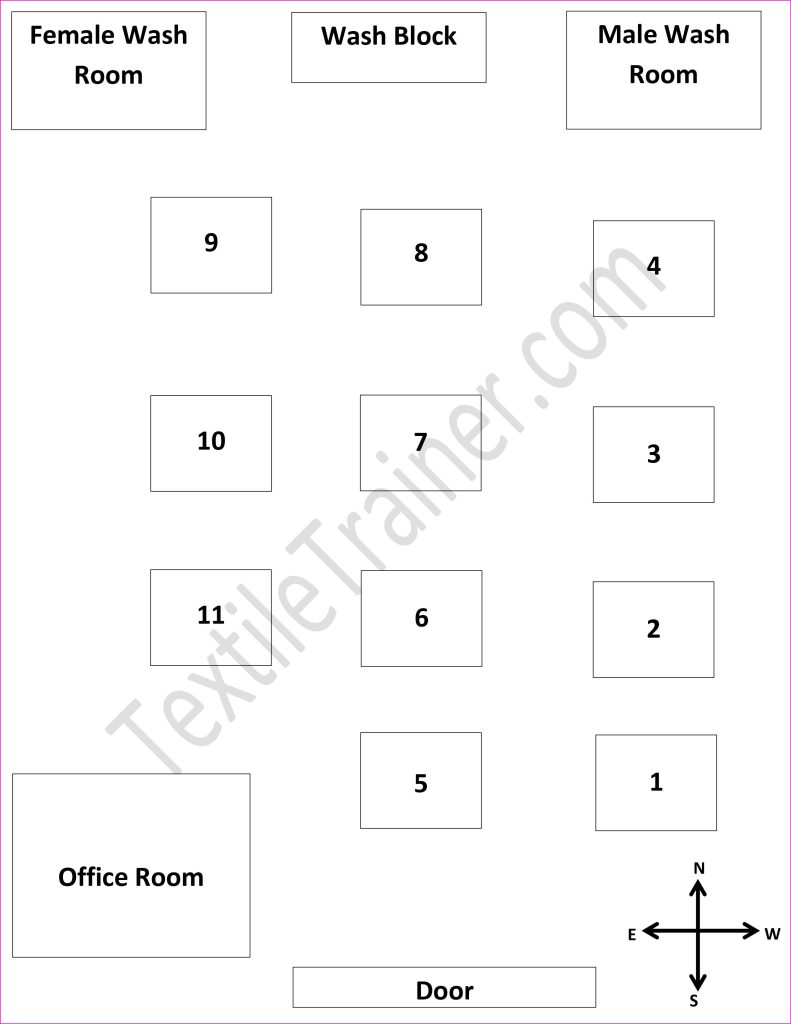

Diagram of Layout Plan of Fabric Lab:

Machine Specifications:

- Machine 01: Jacquard Head

- Capacity:- 245 Neck cord

- Made in Bangladesh

- Machine 02: Hand Socks Knitting Machine

- Machine Diameter: 5 inch

- Machine Gauge: 5

- No of needle: 81 pcs

- No of Feeder: 1 pc

- Made in China

- Machine 03: Dial Linking Machine

- Machine Gauge: 5

- Brand: Golden Tiger

- Made in China

- Machine 04: Single Jersey Circular Knitting Machine

- Machine Diameter : 21 Inch

- Machine Gauge : 24

- No of Needle : 1590 pcs

- No of Feeder : 63 pcs

- No of Cam Box : 63 pcs

- Brand: Orizio

- Made in Italy

- Machine 05: Re-coning Machine

- Working Head: 4 pcs

- Made in Bangladesh

- Machine 06: Air Compressor

- Working Head: 2 pcs

- Brand: Marquismax

- Made in China

- Machine 07: Dobby loom

- No of Heald Frame: 12 pcs

- Reed Count: 112 dents

- Working Width: 56 Inch

- Made in China

- Machine 08: Tappet Loom

- No of Heald Frame: 2 pcs

- Reed Count: 112 dents

- Working Width: 56 Inch

- Made in China

- Machine 09: Pirn Winding Machine

- Machine Capacity: 20 package

- Brand: Bismillah

- Made in Bangladesh

- Machine 10: Braiding Machine

- Working Head: 3 pcs

- Head Capacity: 8 packages, 16 packages and 32 packages

- Made in Bangladesh

- Machine 11: Flat Bed knitting machine

- Working Width: 36 inch

- No of needle bed: 2 pcs

- Machine Gauge: 5 (E)

- No of needle: 360 pcs

- No of Feeder: 1 pcs

- Brand: Golden Tiger

- Made in China

Conclusion:

During this experiment, we learned that an efficient layout plan of fabric lab is critical to a higher level of productivity both on the weaving floor and on the knitting floor. We also learned that the considerations we need to take into account when making an effective layout plan of fabric engineering lab.

You May Read:

- Dynamic Layout Plan of Spinning Lab.

- Bale Breaker Material Passage Diagram: Easy Description.

- Step Cleaner Machine: Simple Working Principle.

- Hopper Feeder Machine in Blow Room with Simple Working Principle.

- Porcupine Opener Machine in Blow Room: Simple Working Principle.

- Scutcher Machine in Blow Room: Feed to Carding Effective Way.

- Material Passage Diagram of Carding Machine with Easy Description.

- Material Passage Diagram of Lap Former Machine.

- Working Principle of Comber Machine: Better Quality Yarn.

- Working Principle of Speed Frame in Ring Spinning with Simple Description.

- Ring Spinning Frame: Working Principle is Describe Very Easy Way.

- Easy Way: Autoconer in spinning working Principle.

- Belt Shifting Mechanism of Speed Frame with Proper Simple Figure.

- Bobbin Building Mechanism of Speed Frame: Easy 3 Step.

You can contribute by submitting articles to enrich our site. Thank you for reading our article. Please share it with your friends and social media.

6 thoughts on “Effective Layout Plan of Fabric Engineering Lab/Lab Report-01”