Experiment Name:

Lab Report: Study on negative tappet shedding mechanism, gearing system, driving mechanism and production system of a tappet loom.

Introduction:

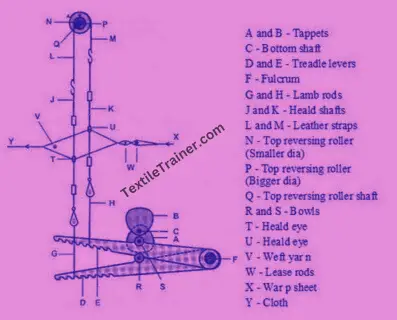

When the rod is to be lifted, followed by intervals of rest, it forms a shed known as tappet. In looms, tappets are generally used for shedding healds. The heald shaft is directly or indirectly connected to the treadle from which it can be operated. The tappet loom accounts for a significant portion of the total weaving output.

Objectives:

- To learn about shedding mechanism of tappet loom.

- To learn about different parts related to this mechanism.

- To know about the gearing system and production system of a tappet loom.

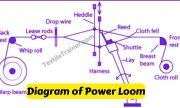

Negative Tappet Shedding Mechanism:

- Motion is received from the bottom shaft by the tappets.

- Tappets rotate when the noses of the tappets strike the treadle lever bowls, which move down with every strike.

- Through the treadle lever, the lamb rod is pulled when tappet strikes on it. This pull also causes the shaft of the heald to move downward.

- A returning spring is attached to the top of the loom frame to return the healing frame to its original position.

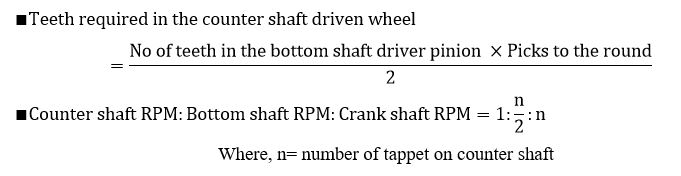

Gearing Diagram:

Related machine parts:

- Motor

- Motor pulley

- V-belt

- Machine pulley

- Crank shaft gear wheel

- Bottom shaft gear wheel

- Tappet

Gearing System:

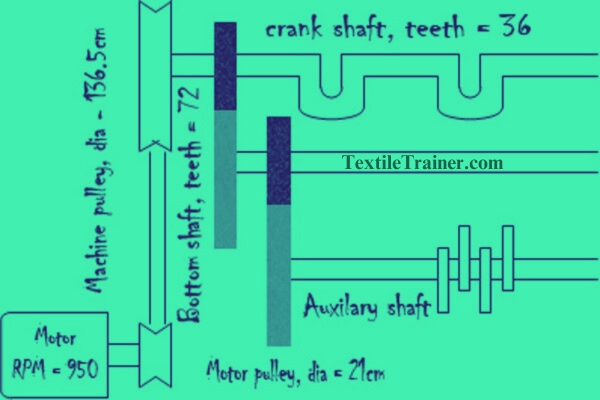

- Initially, the motor is rotated by electricity

- When the motor rotates, the motor pulley also rotates with the same motion

- Using a v-belt, the motor pulley is linked to the machine pulley and the motion of the motor pulley is transferred to the machine pulley.

- In the machine pulley, the crank shaft is enclosed by a gear wheel.

- A bottom shaft gets motion by being in contact with a crank shaft wheel and a bottom shaft wheel. A bottom shaft wheel has double the teeth of a crank shaft wheel, and if the crank shaft rotates once, the weaving cycle is complete.

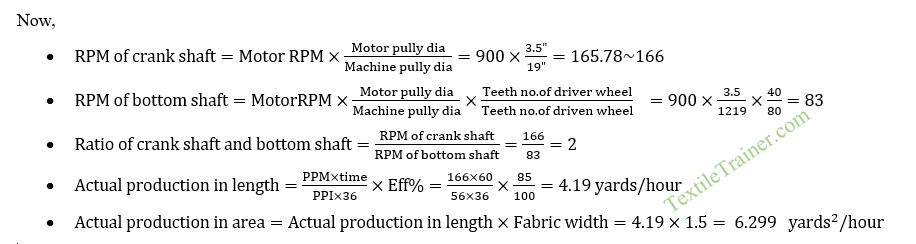

Production Calculation:

Here,

- Motor RPM = 900

- Motor pulley dia = 3.5”

- Machine pulley dia = 19”

- Crank shaft teeth = 40T

- Bottom shaft teeth = 80T

- Picks per inch (PPI) = 56

- Fabric width = 38”

Difference between Tappet and Ordinary Cams:

| Tappet | Ordinary cam |

| It gives motion to a shaft to receive a series of lifts, with intervals of rest. | It gives a continuous reciprocating motion. |

| It is mainly used to produce a Shed. | It may be used for many purposes. |

| All types of tappets are cam. | All cams are not Tappet. |

What is Dwell Period?

Tappets should be constructed in such a way that the healds remain stationary while the shuttle passes through. This stationary period is known as the “Dwell of Heald.” or “Pause or Dwell Period.”

What is Counter Shaft?

The plain weave tappets are usually, place on the bottom shaft as the former give two picks to the round. But in case of weaving twill or satin, the tappets tare always placed on a short shaft known as counter shaft. The bottom shaft imparts motion to the counter shaft either ‘directly or through a carrier wheel. The counter shaft must always rotate, once for as many picks as there are to round.

Conclusion:

During this experiment, we learned about negative tappet shedding mechanism and its gearing diagram. We also learned how to calculate production. Thanks to our teacher for sharing this experience with us.

You May Read:

- Effective Layout Plan of Fabric Engineering Lab.

- Basic Principle of Weaving: Very Easy Way.

- Yarn Passage Diagram of Pirn Winding Machine is Described Easy Way.

- Yarn Passage Diagram of Circular Knitting Machine.

- Yarn Path Diagram of Power loom with Basic parts.

- Dynamic Layout Plan of Spinning Lab.

- Bale Breaker Material Passage Diagram: Easy Description.

- Step Cleaner Machine: Simple Working Principle.

- Hopper Feeder Machine in Blow Room with Simple Working Principle.

- Porcupine Opener Machine in Blow Room: Simple Working Principle.

1 thought on “Negative Tappet Shedding Mechanism with Simple Gearing System/ Lab Report -02”