What is Heald?

Heald is composed of two wooden or iron laths upon which a series of twine cords or wires are suspended. In the middle of each cord or wire there is an “eye” through which a warp thread passes. Cotton or worsted wool healds are firmly knitted over the laths, whereas wire healds are suspended on two wire rods fastened to the top and bottom laths. The number of heald shafts to be used is determined by the drafting place of the design. 7 types of heald used in loom will be discuss in this article.

Functions of Heald Shaft:

- It maintains the order or sequence of the warp threads.

- Shedding occurs when it forms.

- Fabric patterns are formed by elevating and depressing the required number of heels in a predetermined and sequential order.

- It helps to detect broken ends.

Necessity of Heald:

- A heald is essential for dividing the warp threads into two layers after they have been carefully arranged.

- Healds facilitate the precise interlacing of warp and weft threads, which creates the desired fabric structure.

- A heald makes possible the proper selection and manipulation of warp threads in successive repeats of a pattern.

- Modern looms have enabled a significant advancement by allowing the warp threads to be placed horizontally.

- The use of healds increases production efficiency by automating and optimizing the shedding process.

Types of Heald:

Various types of heald have been tried and used during many centuries past. Some of the ancient and modern heals are as following:

- Primitive healds.

- Single-clasped healds.

- Double-clasped healds.

- Eyed healds.

- Healds with mail eyes or metallic clips.

- Wire healds.

- Doup healds.

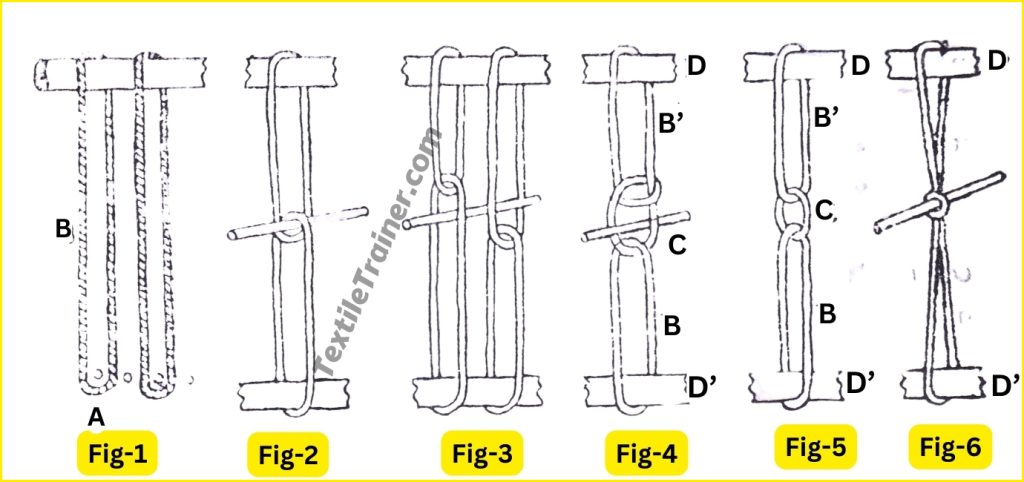

1. Primitive Heald:

The first primitive heald which was used in a horizontal loom consists of a series of twine loops, each passing round a warp thread and fastened to a wooden rod. The number of loops on a rod and the number or rods employed depend upon the breadth and closeness of warp threads. Primitive heald is shown in figure-1

2. Single clasped heald:

Single clasped healds consists of passing two series of threads into separate rods. The warp threads are kept in proper order and thereby the production of the loom is increased largely. Single clasped heald is shown in figure-2

3. Double clasped heald:

The first change consisted in doubling the number of loops on each pair of rods and in causing those loops to lie in two ranges. A warp thread was then passed over one loop and under another, so that as the rods rose or fell, the warp was positively moved without undue strain. Figure-3 is shown double clasped heald

4. Eyed heald:

The eyed healds consist of knitted eyes about the middle of the twine. B and B’ are loops which for cotton manufacturing vary between 10” and 14” or 25.4 cm. and 35.5 cm. from top to bottom. C is an eye whose depth is ¼” of 0.635 cm for cotton goods and 5/8” or 0.95 cm for silk or synthetic goods. D and D’ are the laths or shafts. Figure-4 is shown eyed heald.

5. Healds with mail eyes or metallic clips:

Eyed healds (figure-6) sometimes support steel, brass, glass or other metal eyes. Such healds are usually employed when rough, knotty warps have to be woven, but glass is principally used for silk and occasionally for cotton gauze. They all offer less resistance to the passage of warp than twine eyes and wear better, but they usually take more room.

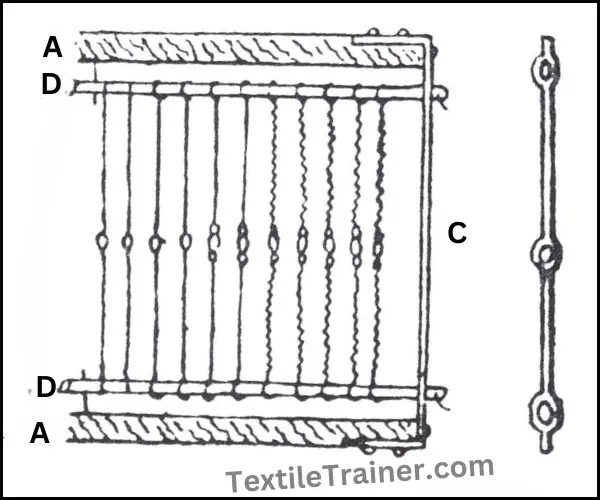

6. Wire healds:

Wire healds are made of round, flat or twisted wires, small loops being left in the center for the ends to pass. The wires are loosely placed on laths or bars or slider rods D and self-adjusting. Now-a-days, wire healds are largely used in the cotton industry.

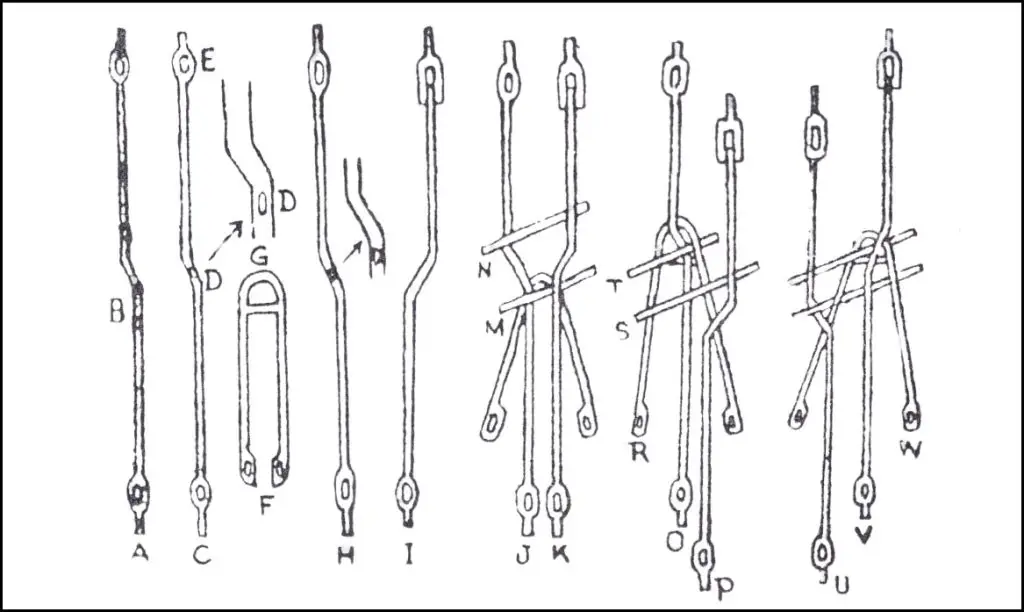

7. Doup heald:

Doup heald is the most efficient and latest healds for weaving. There are tow doups and a slip. Each doup is made in two parts and may be termed a double heald. The two pars are at A and C. the part A is cranked and has a small step at B. C is cranked at D and is made with a hole for the bottom part of the heald to pass through. At the upper part E the slot is longer, and has a step upon which the upper end of A may rest when threaded through. At the top half, the two heals are as one by interlocking, but at the bottom they are separate. The healds are slotted at botth ends for the use of slider rods. The healds H and I are reversed in position. The total length of the healds is 13 ¼’ or 33.65 cm and slip F is 6 1/8” or 15.55 cm long. Both the legs and the upper end G of the slider rod are slotted. Through the half moon shaped end G of the slip, the crossing thread passes. At M, the crossing thread is drawn through the slip G, and the stationary thread N is passed through the heald on the stationary shaft behind both doups, and then passed between the doups. When the left doup O is raised, it takes with it the slip R. This causes the crossing thread T to be lifted on the left side of the stationary thread S, and a pick is then inserted with the heald P down. On the next pick the healds and slip are reversed in position, the heald U down and the heald V and slip W up. This completes weaving of the simplest kind of gauze. It may be noted that the slip cannot be pulled down any further than where the double healds J and K interlock at their centres.

You May Read:

1 thought on “7 Types of Heald Used in Loom: Simple Note with Figure”