What is Loom?

A weaving machine is called a loom. The loom has been in use for thousands of years. It has undergone significant changes over the years, but its basic principles and operations remain the same. The warp yarns are taut within the loom, and filling yarns are inserted and pushed into place to make the fabric.

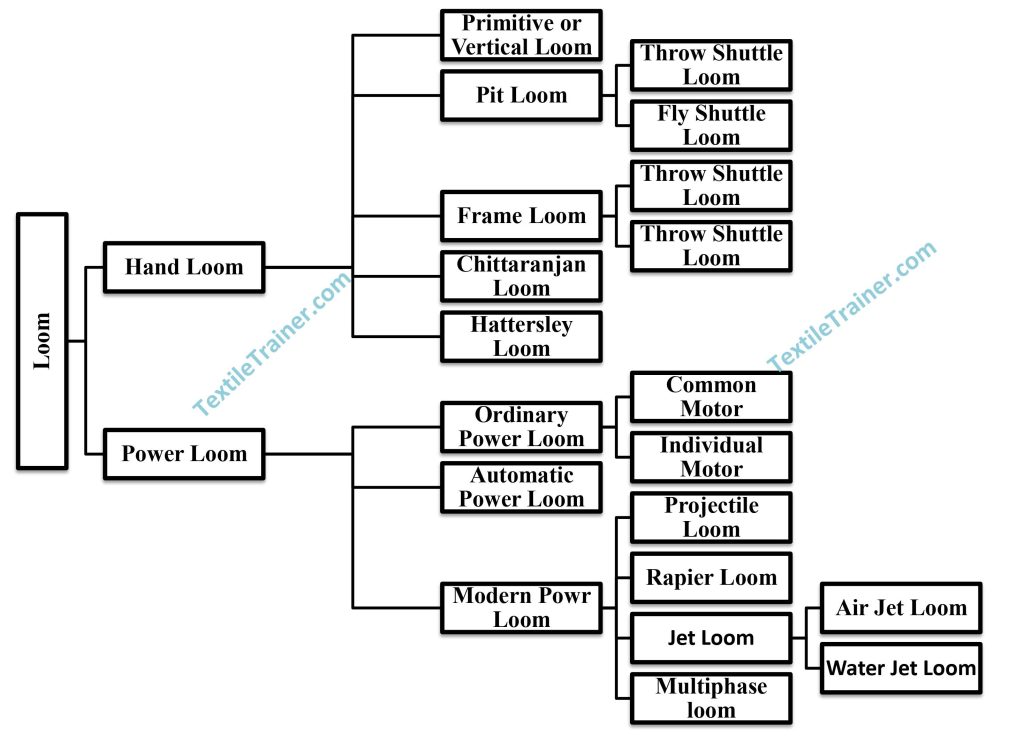

Classification of Loom:

Now I will short brief with short note of classification of loom

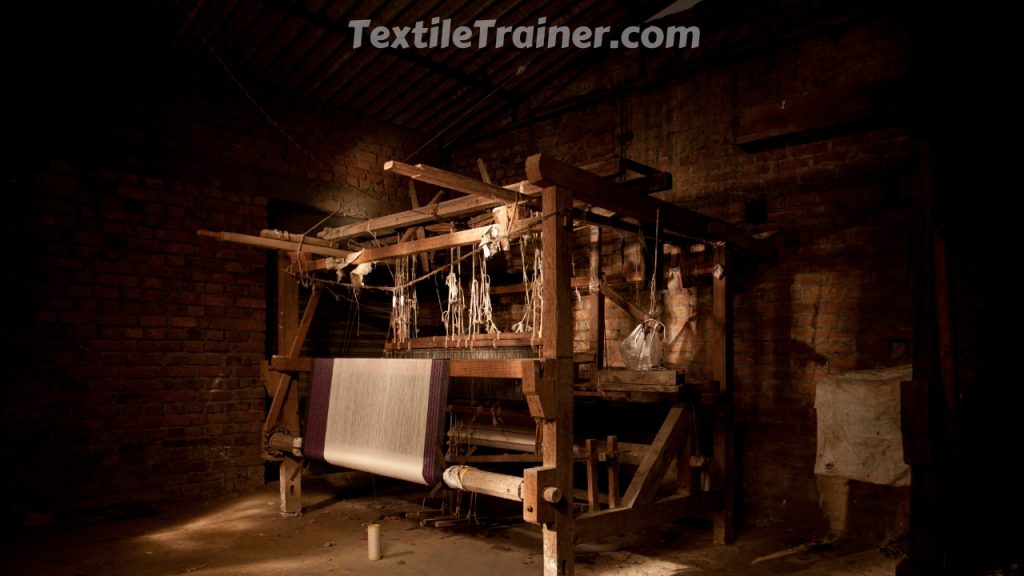

Hand Loom:

Handlooms are looms used to weave cloth without using electricity. They are usually used in weavers’ homes on pit looms or frame looms. The process of weaving involves interlacing two sets of yarns – the warp (length) and the weft (width). Below are some of the most important types of hand looms:

1. Primitive or Vertical Hand Loom:

As with primitive looms, the frame is normally buried in the ground, but here the work is done inside the pit using both feet. Bamboo is used for the framework. These types of looms were known to be in use between 5000 and 6000 years B.C. They are still used today for weaving silk shirts and sharees, silk pieces, muslin, etc., by derivative weavers.

2. Pit Loom:

A pit loom is set with four posters buried in the ground and an overhang slay. In pit looms, the warp yarn is soaked in moisture inside the pit in order to improve weaving. In this loom, the combination of slay and shuttle boxes. John Key of Bury, England invented the fly shuttle in 1773. This invention had a profound impact on the development of weaving history.

3. Frame Loom:

Almost all frame looms have the same mechanism as ground looms. The loom was constructed from rods and panels fastened at the right angles in order to construct a form similar to a box to make it more handy and manageable. Due to its portability and economy, frame looms have been utilized for centuries.

4. Chittaranjan Loom:

A Chittaranjan loom is a type of semi-automatic loom made of iron and wood. Chittaranjan loom is commonly known as Japanize loom in Bengali.

5. Hattersley loom :

The Hattersley loom was developed by George Hattersley and sons of Kighley in the West Yorkshire area of England in 1856. This type of loom operates in the same manner as a power loom, but does not allow the slay to move.

Power Loom:

A power loom is a mechanized loom, and was one of the key developments in the industrialization of weaving during the early Industrial Revolution. Edmund Cartwright designed and patented the first power loom in 1785. This device was designed in 1834 by James Bullough and William Kenworthy, and was dubbed the Lancashire loom. It was further refined for 47 years until it became entirely automatic by the Howard and Bullough company. There are three types of power looms:

1. Ordinary Power Loom

The loom runs on a power system. Without the let-off motion, all primary and secondary motions are automatic. When warp or weft yarn breaks, the loom must be stopped manually.

2. Automatic Power Loom

There are automatic primary and secondary movements present here, as well as tertiary movements present here. The shuttle changes are automated as well.

3. Modern Power Loom

There is no shuttle used here, only weft insertion is done by multiple mechanisms such as projectile air, water, etc., and all primary, secondary, and tertiary emotions are automatically categorized. Productivity is high and quality is excellent of modern loom. Now-a-day, following types of modern power looms are available used in factory.

- Projectile Loom: An innovative concept, Roshman, has been transformed into a viable commercial weaving machine by the Sulzer brothers of Winterthur, Switzerland, pioneers in the field of projectile methods of weft insertion. It was introduced in 1953. This modern loom is characterized by a weft insertion system. The weft thread is inserted into the warp threads using a shuttle, which measures 90 mm in length and weighs about 40 grams. It is called a gripper projectile.

- Rapier Loom: With the rapier inserted into the weft, it is mechanically a modern and refined version of the primitive method in which the weft was secured in a stick’s slot. Currently, gripper heads are attached to flexible tapes or rigid rods called rapiers. As the father of modern rapier technology, Mr. Gabler built a rapier device in 1922 on a cotton weaving machine.

- Air Jet Loom: Weft insertion by means of air jet made a major breakthrough in the early 1970s, and its significance is growing because it can weave a wide range of fabrics at a rapid weft insertion rate of 2000 meters per minute. Brooks makes the first attempt to use compressed air steam instead of shuttle in 1914.

- Water Jet Loom: Satyr developed the first loom with a water jet for insertion of weft. This loom was first displayed at the Brussels textile Machinery Exhibition in 1995.

- Multiphase Loom: The phase number of a loom is defined as the average number of shuttles or weft carriers inserting weft simultaneously. It is shown that existing multi-phase looms must have high phase numbers to compensate for their low shuttle velocity. A moderate increase in phase number would yield equally high weft-insertion rates in looms with high-velocity flying shuttles. The proposed alternative would eliminate many of the textile and engineering problems associated with existing multiphase looms by dividing the shedding and beat-up motions into comparatively small sections.

Im grateful for the blog article.Much thanks again. Much obliged.