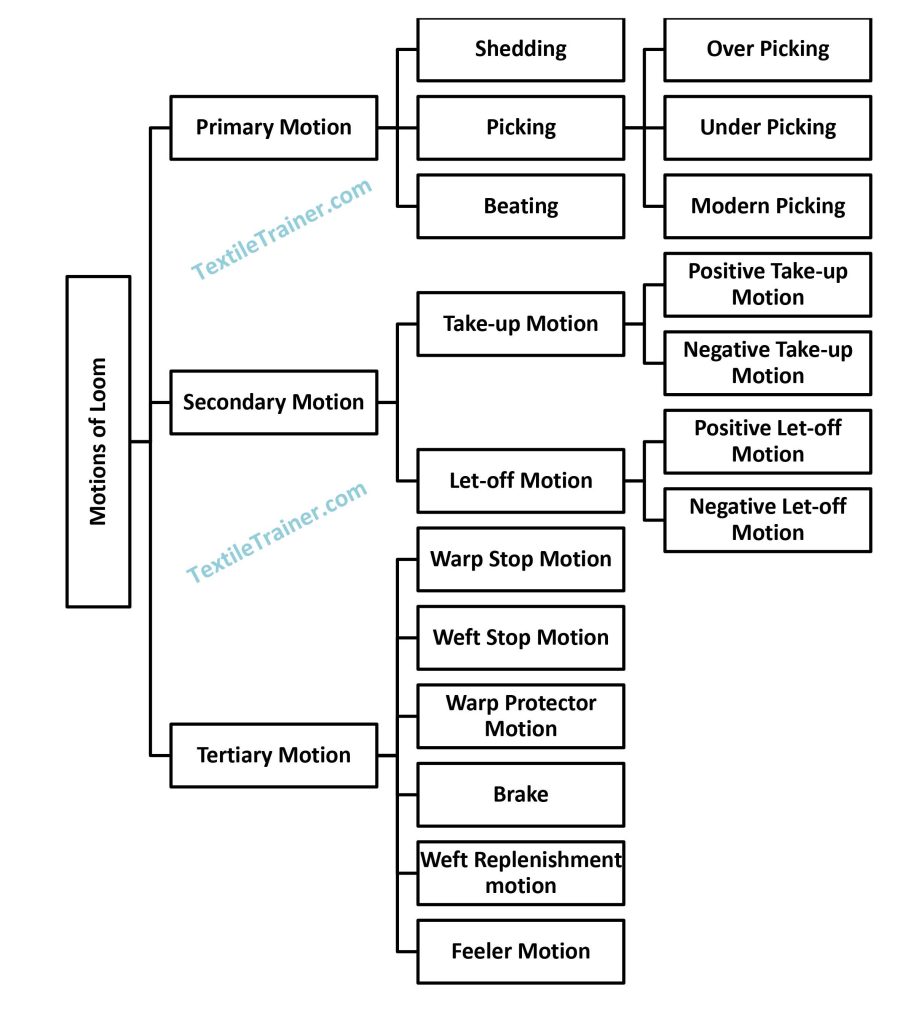

Motions of Loom:

In fabric production, Motions of loom are essential. Different loom motions of a loom machine provide different weaving facilities. Therefore, weaving stands for interlacing warps and wefts. To make a normal or fancy-designed fabric, weaving indeed is essential. There are many types of looms that facilitate the weaving process. The looms run on motion mechanisms, and they are an essential piece of equipment for weaving. The loom machine is used to weave fabric in two ways, such as automatic system and manual system. Here, I will describe the motion of the loom machine.

Types of Motions of Loom:

Now I will discuss all the motions of loom one by one.

Primary Motions:

The primary motions are designed to those motions or movement of weaving in absence of any them weaving is not practicable. Primary motions of weaving are the following:

- Shedding.

- Picking

- Beating.

1. Shedding:

Shedding is dividing the warp threads into two layers, one above the other, for the passage of shuttle with weft thread. Shed is produced by means of healds or harnesses. Shedding is broadly divided into two classes. They are:

- Closed shedding.

- Open shedding.

2. Picking:

Picking is the second of the primary motions in weaving. It is consists in passing a pick of weft between the upper and lover lines of a divided warp. Picking mainly three types. They are:

- Over picking: Over picking occurs when the picking arm is placed above the shuttle box.

- Under picking: Under picking occurs when the picking arm is placed below the shuttle box.

- Modern picking: In modern picking system, there are no shuttle is used. In modern picking system, air jet, water jet, projectile and rapier is used in stead of shuttle.

3. Beating:

The beating is the third of the primary motions in weaving. It consists in diving the last pick of weft to the fell of the cloth. This is accomplished by the “going part” with the help of a reed fixed in the sley. The sley is given a sudden and quick movement towards the fell of the cloth by the cranks in the crankshaft.

Secondary Motions:

Secondary Motions are next in importance to primary motions. Their presence is also necessary for continuous and regular weaving of a piece of fabric. There two types of secondary motions. They are:

- Take-up motion.

- Let-off motion.

1. Take-up motion:

This operation consists in taking-up the cloth when being woven and then winding it on to the cloth roller. The function of the take-up motion is to drawn a fabric to the cloth roller regularly. There two types of take-up motion.

- Positive take-up motion: The take-up motion is said to be a positive when cloth is taken up on to the cloth roller pick by pick automatically during weaving by means of a train of wheel is called positive take-up motion.

- Negative take-up motion: The take-up motion is said to be a negative when cloth is taken up on the cloth roller by manually operate.

2. Let-off motion:

This operation consists in letting-off of the warp wound on the weaver’s beam when the cloth is taken-up on to the cloth roller. Both taking-up of the cloth and letting-off of the warp are done simultaneously, so that the warp may always remain parallel with the floor in the form of a continuous sheet and that no unnecessary strain is put upon it. Let-off motion also two kinds. They are:

- Positive let-off motion: Positive let-off motion involves turning the weaver’s beam at a rate that maintains the length of warp sheet between cloth fell and weaver’s beam, while the tensioning mechanism is separate from the beam-driving mechanism. Positive let-off motion is generally controlled by means of a ratchet wheel and a pawl fixed at one end of the warp beam, the pawl being centred at the framing.

- Negative let-off motion: in the negative let-off motion, used in powerlooms, the warp is controlled by means of ropes or chains, leavers and weights.

Tertiary Motions:

Generally, tertiary motions are not needed for fabric production, but they can be used for quality and productivity purposes, stopping the loom as soon as a problem occurs, thereby ensuring quality. Some most important tertiary motion is discussed below.

- Warp stop motion: This motion is applied when a warp thread breaks or becomes excessively loose. When a drop wire falls due to end breaks, the broken end can be repaired and handled by the operator.

- Weft stop motion: When a weft breaks or runs out of the pirn, this motion stops the loom from running. If the loom runs even after a weft breaks, no cloth is woven except warp threads.

- Warp protector motion: It prevents the warp thread from becoming damaged by stopping the loom as soon as the weft fails to reach, and boxes properly into either winder. During picking, this motion protects the warp threads by stopping the loom when the shuttle fails to reach the selvedge side and boxing properly into either shuttle box. When a shuttle does not reach its appropriate box, a loom must either be immediately stopped by a fast reed motion or gradually stopped by a loose reed motion.

- Brake motion: If a weft yarn breaks on a loom, this mechanism stops the loom. A brake is a device that applies artificial frictional resistance to a moving body in order to stop the motion of a moving body. It stops the loom immediately whenever required, and the weaver uses it to fix broken ends and picks.

- Weft replenishment motion: Weft yarn is continuously supplied to the loom when the supply package becomes depleted. With this motion, a depleted supply package is switched to a full supply package to ensure uninterrupted filling insertion.

- Feeler motion: By using this motion, it is possible to find out whether or not the weft yarn in a pirn is almost used up.

You may read: