Gearing Calculation of Carding

Raw cotton fibers are transformed into a continuous and uniform web through the use of a cotton carding machine in the initial stages of textile processing. Two critical aspects of cotton carding are discussed in this study: motion transfer diagrams and draft calculations. A motion transfer diagram reveals the intricate movements within the machine, while a draft calculation reveals how fibers attenuate and elongate during the carding process. In combination, these analyses provide a comprehensive understanding of the carding machine’s functionality and help improve yarn quality and efficiency by optimizing carding operations. Here, I tried my best to present gearing calculation of carding machine easy and simple way.

Formula for Gearing Calculation of Carding:

Below two formula is require for gearing calculation.

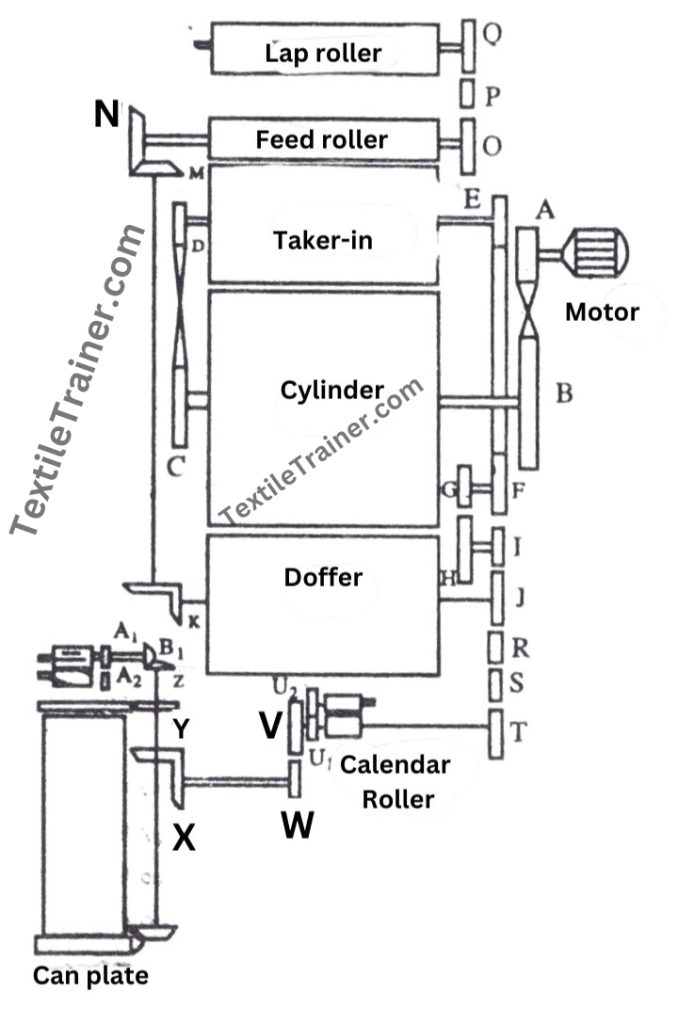

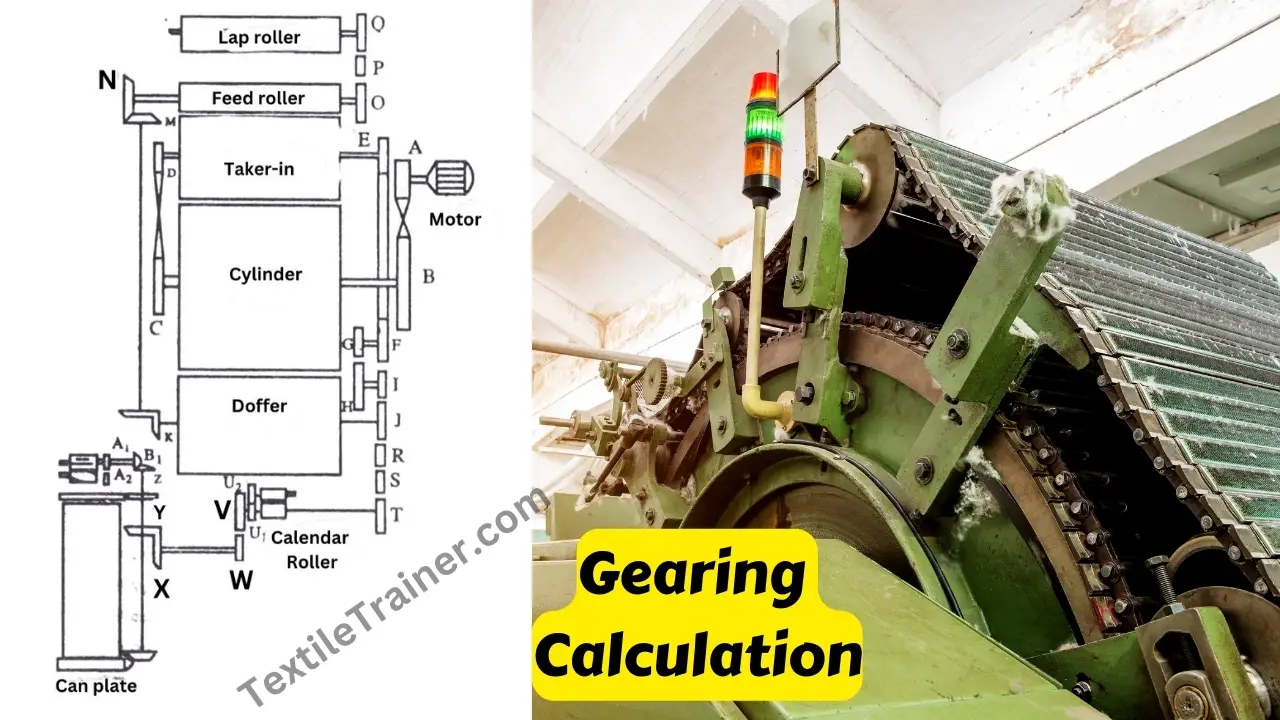

Gearing Diagram of Carding Machine:

Different pulley diameters and Number of wheel teeth of carding machines:

| Parts name | Diameter/Teeth | Parts name | Diameter/Teeth |

| A=Motor pulley | 4.125 inch | O= Feed roller wheel | 17 |

| B= Cylinder pulley | 23 inch | P= Carrier wheel | |

| C= Cylinder of under pulley | 19 inch | Q= Lap roller wheel | 48 |

| D= Taker-in pulley | 7 inch | R & S= Carrier wheel | |

| E= Taker-in of under pulley | 7 inch | T= Calendar roller block wheel | 28 |

| F= Slow-motion pulley | 10.25 inch | U1 & U2= Pair calendar roller wheel | |

| G= Slow-motion stand wheel | 32 | V= Calendar under wheel | 32 |

| H= Compound carrier wheel | 112 | W= Short shaft wheel | 15 |

| I= Burro wheel | 32 | X= Drive wheel to upright shaft | 20 |

| J= Doffer wheel | 180 | Y= Upright shaft med bevel wheel | 20 |

| K= Doffer of under bevel wheel | 24 | Z= Upright shaft top bevel wheel | 20 |

| L= Cross shaft bevel wheel | 34 | A1 & A2= Coiler calendar roller pair wheel | 20 |

| M= Change pinion | 20 | B1= Coiler calendar roller wheel | 20 |

| N= Plate wheel | 120 |

Some important roller’s diameter of carding machine:

| Roller name | Diameter (inch) |

| Cylinder | 50 |

| Taker-in | 9 |

| Feed roller | 2.5 |

| Lap roller | 6 |

| Doffer | 27 |

| Calendar roller | 4 |

| Coiler calendar roller | 2 |

| RPM of motor | 955 RPM |

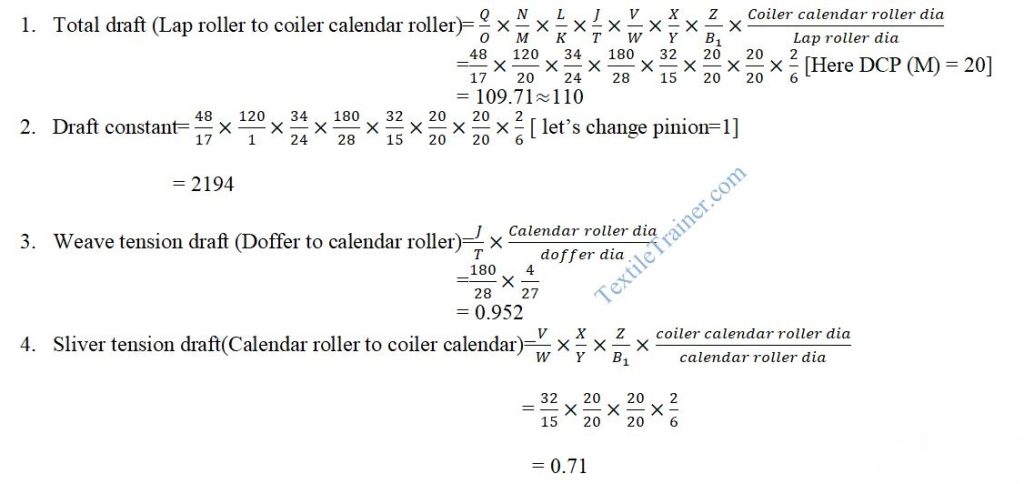

Gearing Calculation of Carding:

Draft calculation:

The action of reducing the thickness or linear density of the feed material by drawing is known as drafting.

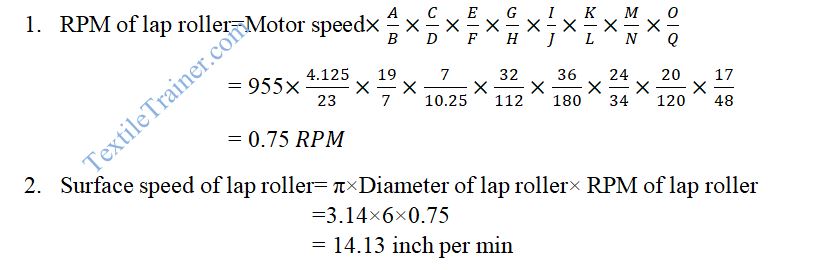

RPM and Surface Speed:

Basically, RPM (Revolutions per minute) refers to how many rotations a rotating object makes in one minute. Surface speed refers to how fast something moves on its surface.

Lap Roller RPM and Surface Speed:

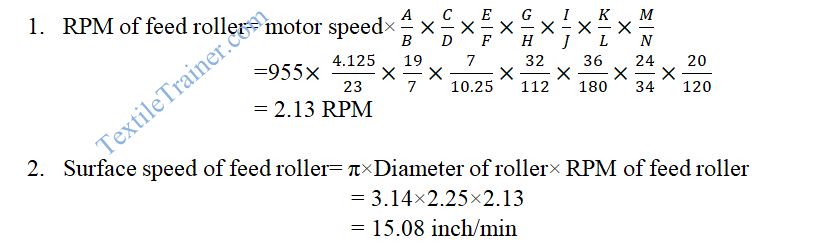

Feed Roller RPM and Surface Speed:

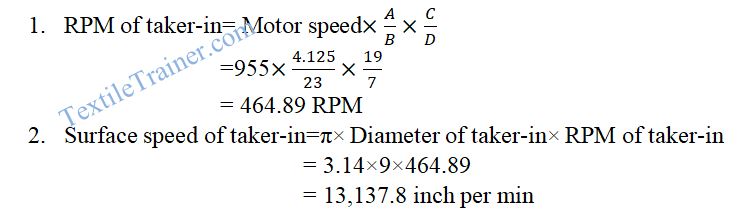

Taker-in RPM and Surface Speed:

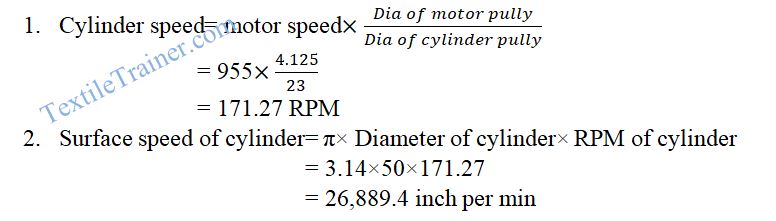

Cylinder RPM and Surface Speed:

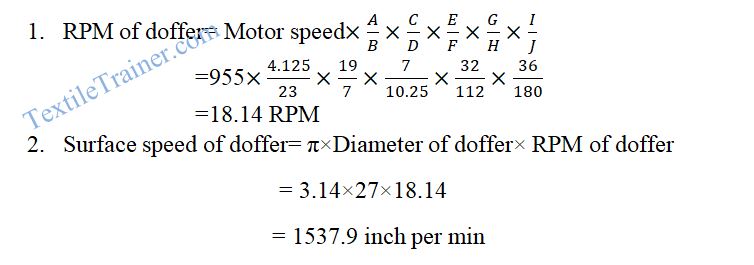

Doffer RPM and Surface Speed:

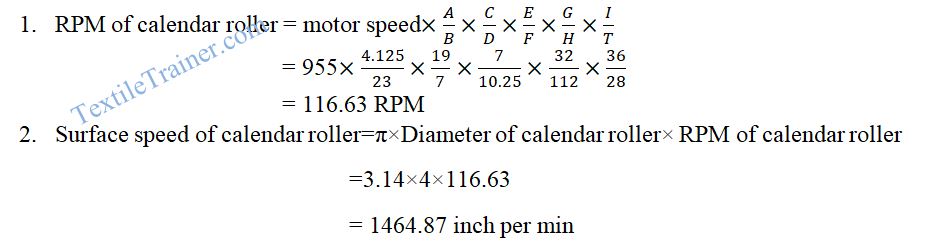

Calendar RPM and Surface Speed:

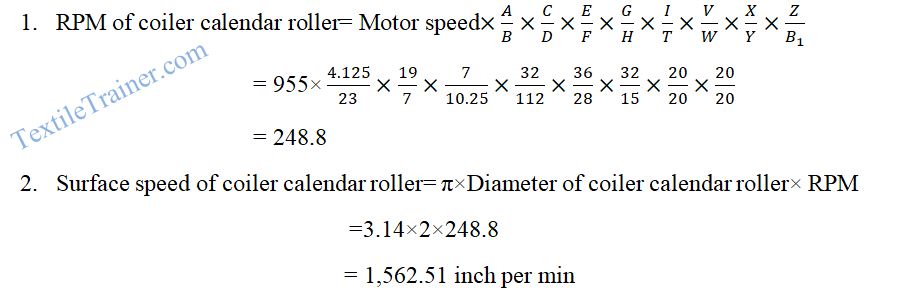

Coiler Calendar RPM and Surface Speed:

By investigating cotton carding machines’ motion transfer diagram and draft calculation, we can gain a deeper understanding of gearing calculation of carding machine. By laying the groundwork for advancements in technology, operational strategies, and quality control within cotton carding operations, this study contributes valuable insights to the industry’s quest for precision and efficiency.

You May Read:

- Calculation of Carding Machine with 15 Exercise and 10 Important Formula

- Blow Room Calculation A to Z: Essential 8 Formula and Abundant Practice.

- Sizing Calculation: 10 Essential Formula for Accurate Calculation.

- Yarn Winding Calculation: Easy Formula and 10 Abundant Practice.

- Sewing Thread Consumption Shortcut Easy Formula with 5 Exercise.

- Easy Dyeing Recipe Calculation Formula with Proper Example.

- Yarn Count Measurement in Shortcut Easy Method with 10 Exercise.

- Determination of fabric consumption calculation for woven basic pants by Easy Formula.

- Calculation of Fabric Consumption for a Long Sleeve Basic Shirt in Easy Formula.

Reference:

- Chowdhury, M. F. (2016). Manual of short staple spinning. Dhaka: Granthanir Prokashoni.

- Hossain, M. S. (2014). Introduction to Textile Engineering. Dhaka: Books Fair Publications.

- Kadolph, S. J. (2006). Textiles. New Delhi: Pearson Education.

- Karim, E. A. (2010). Textile Calculation. Dhaka: Prime Publications.

I simply enjoy the useful details you provide in your writings.