Introduction:

Calculation of carding machine are an integral part of the carding process. In this article, I will discusses calculation of carding machine production with most important formula. From this article, we also get 15 exercise of carding machine calculation. A carding operation disentangles, cleans, and mixes fibers to produce a continuous web or sliver that can be processed further. It involves passing fibers between surfaces that move differentially and are covered with card clothing. The carding process opens fibers up to more or less single fibers. Dust, dirt, small trash particles, nep, and other impurities are removed. Fiber blending and parallelization are also performed at this stage. This is why Carding is known as the “Heart of Spinning”.

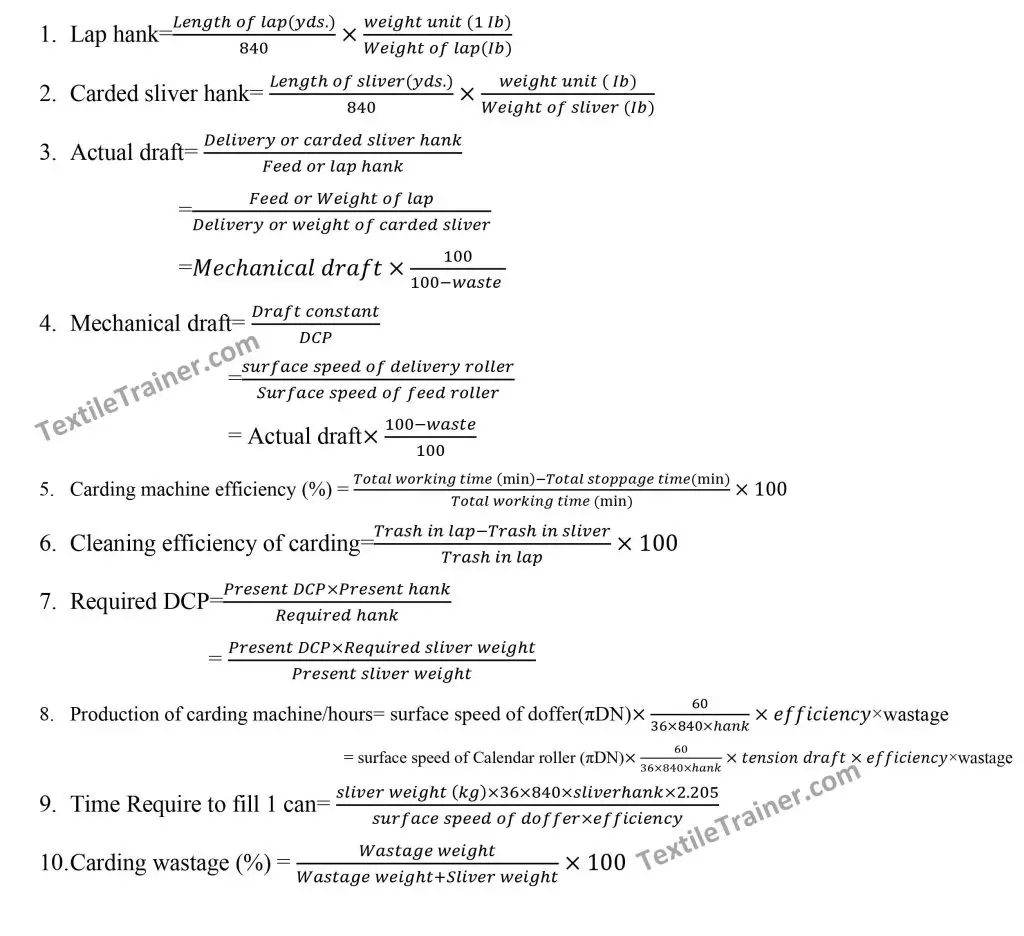

Calculation of Carding Machine’s Formula

I have listed below 10 important formula for carding machines that you should know

Exercise

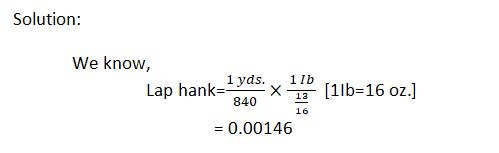

Problem-1: Find the lap hank if lap weight is 13 oz/yds.

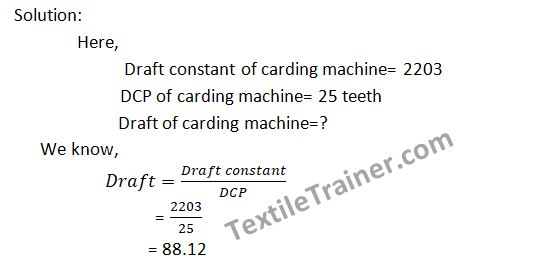

Problem-2: If the draft constant of a carding machine is 2203 and the DCP is 25 teeth, what will be the draft of the machine?

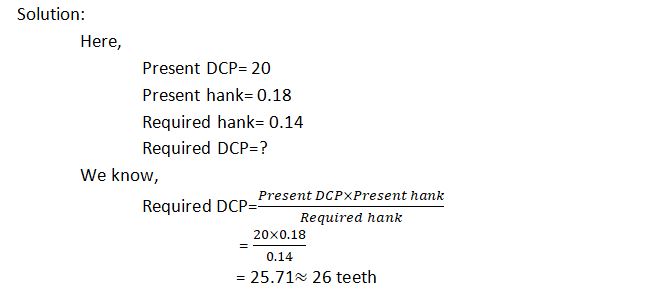

Problem-3: Find required DCP of a carding machine when present DCP is 20, present hank is 0.18 and required hank is 0.14.

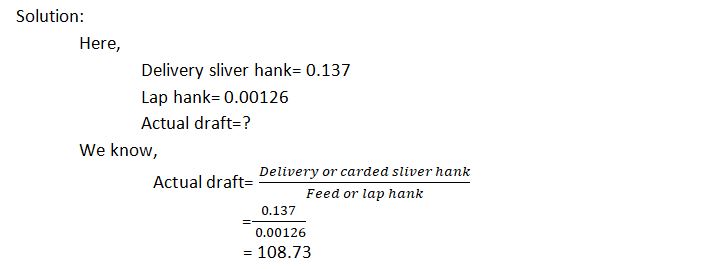

Problem-4: Find actual draft if delivery sliver hank is 0.137 and lap hank is 0.00126.

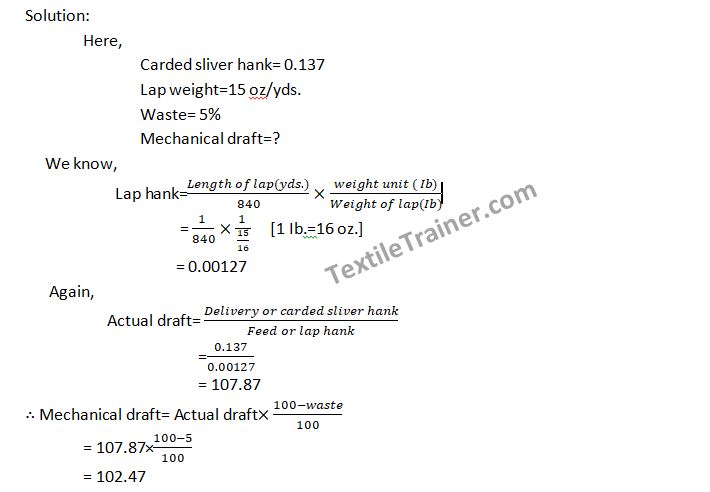

Problem-5: If a carding machine produces a sliver of 0.137 hunk from a lap weighing 15 oz./yds. with 5% waste, what is the mechanical draft of the machine?

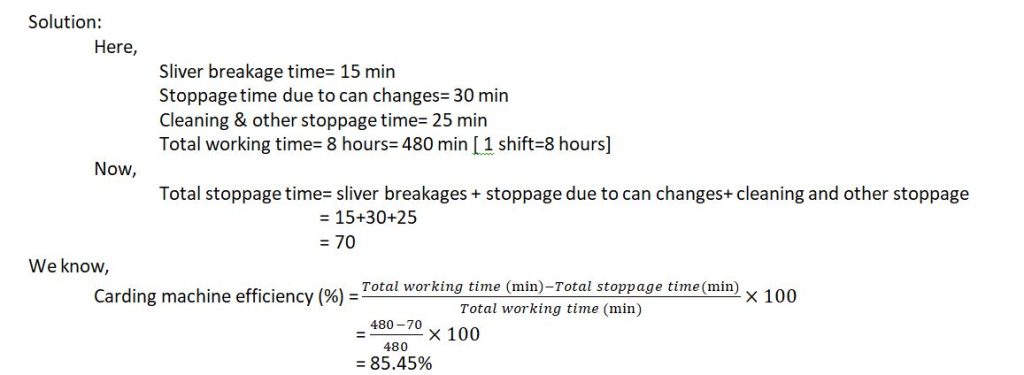

Problem-6: Calculate the carding machine efficiency per shift if sliver breakage time is 15 min, stoppage time due to can changes is 30 min, cleaning & other stoppage time is 25 min.

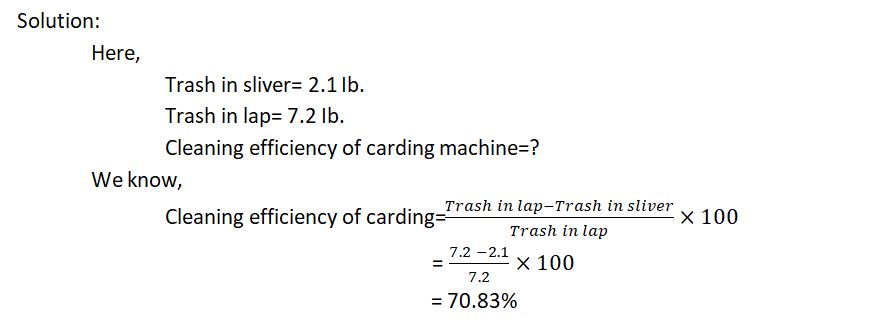

Problem-7: Calculate the cleaning efficiency of carding machine if trash in sliver 2.1 Ib. and trash in lap 7.2 Ib.

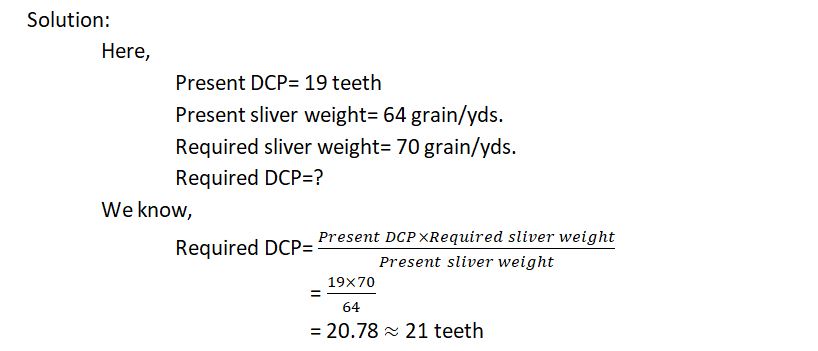

Problem-8: If a carding machine can produce a sliver weighing 64 grains/yds. with a DCP of 19 teeth, find how many teeth DCP is required to produce a sliver weighing 70 grains/yard?

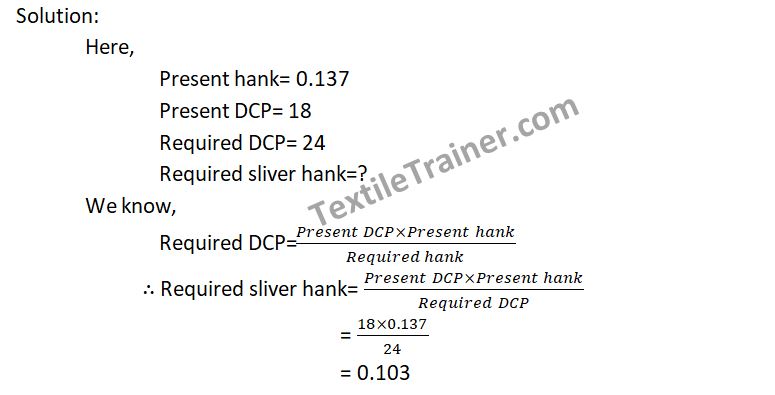

Problem-9: Find the required sliver hank when present sliver hank is 0.137, present DCP is 18 and required DCP is 24.

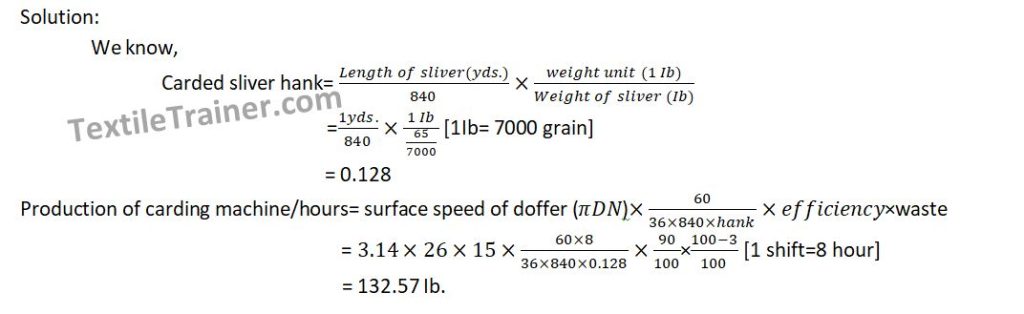

Problem-10: Find out production per shift in modern carding m/c by using following date

- Doffer speed (N) = 15 RPM

- Doffer dia(D) = 26 inch

- Delivery sliver weight = 65 grains/yard

- Efficiency = 90%

- Waste = 3%

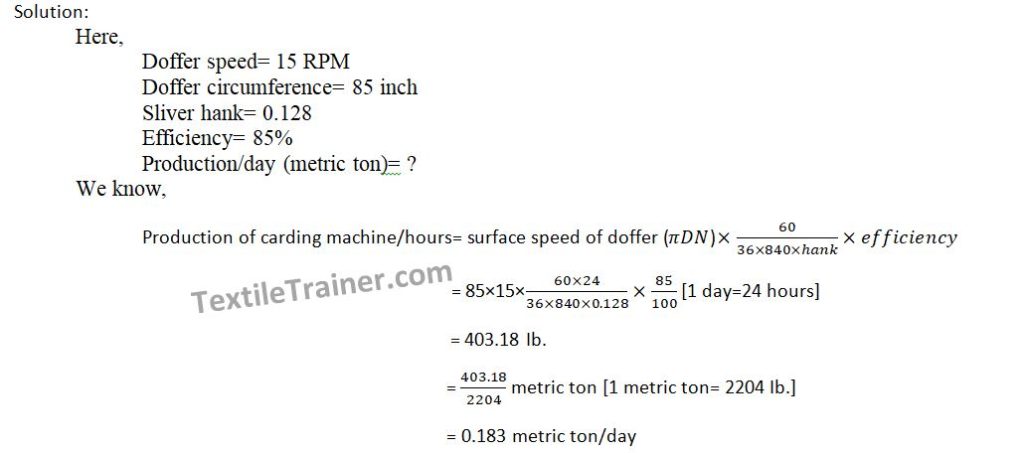

Problem-11: A carding machine has a doffer rotation speed of 15 RPM, a doffer circumference of 85 inches, a sliver hank is 0.128 and an efficiency of 85%. Fine how many metric tons of carding machine production per day?

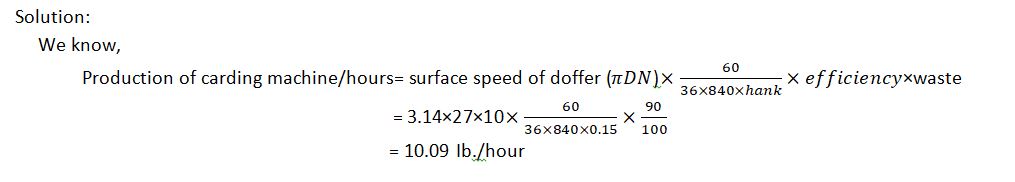

Problem-12: Find the production per hour of a carding machine by using following date:

- Doffer speed= 10 RPM

- Doffer dia= 27 inch

- Sliver hank= 0.15

- Machine efficiency= 90%

- Production/hour=?

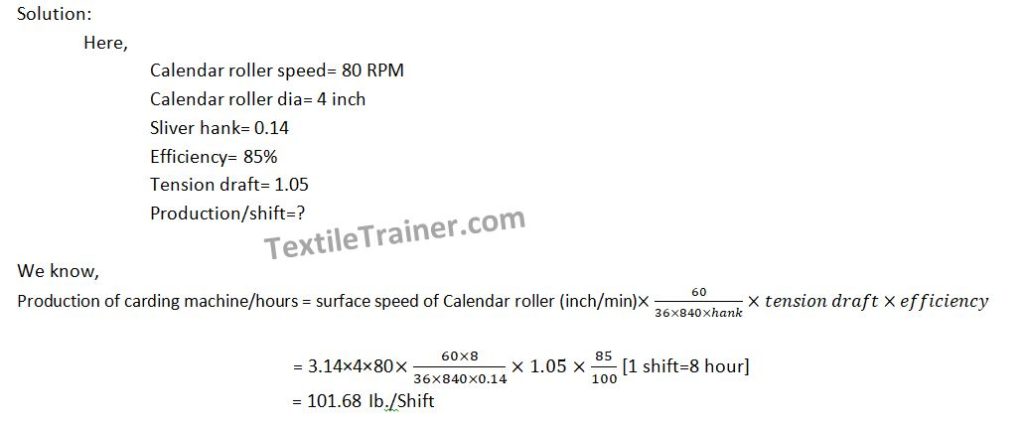

Problem-13: The rotation speed of the calendar roller of a carding machine is 80 RPM, the diameter of the calendar roller is 4 inches, the sliver produced is 0. 14 hank. If the efficiency of a carding machine is 85%, and the tension draft of the machine is 1.05, find the production per shift of the machine

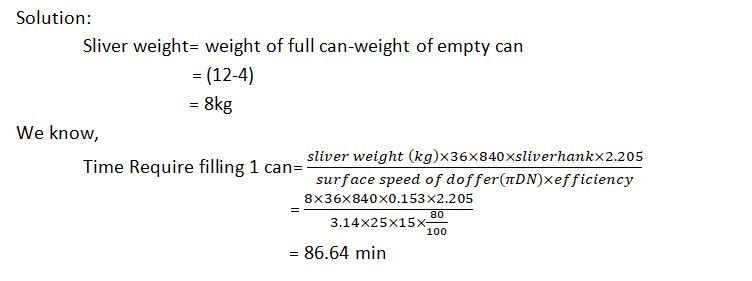

Problem-14: Find time required to fill one can from below data

- Weight of Empty can = 4 kg;

- Weight of full can = 12kg

- Sliver Hank = 0. 153,

- Doffer dia (D) = 25 inch,

- Doffer speed (N) = 15 RPM,

- Efficiency = 80%;

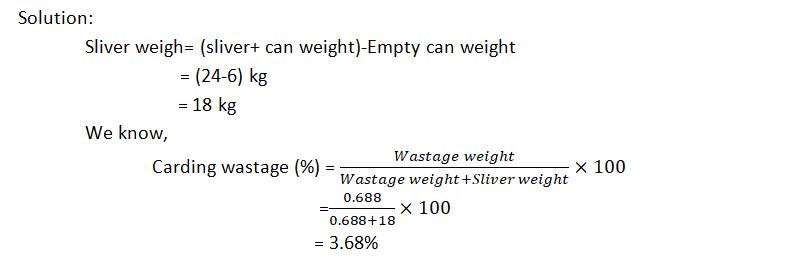

Problem-15: Calculate the wastage% using the following data-

- Empty Can Weight = 6 kg

- Sliver + Can Weight = 24 kg

- Wastage Weight = 0.688 kg

You May Read:

- Objectives and basic function of carding machine.

- Working principle of carding machine.

- Why carding is called heart of spinning?

- Operating zone of carding machine.

- Neps in carding machine.

- Function of carding machine.

- Types of card clothing with advantage and disadvantage.

- Flexible card clothing vs metallic card clothing.

- Action of carding machine.

- Stripping in carding.

Nice post. I learn something totally new and challenging on websites

I appreciate you sharing this blog post. Thanks Again. Cool.

I loved your post.Really looking forward to read more. Much obliged.