Card Clothing:

Card clothing can be classified three categories. In this article, we describe best differences between flexible and metallic card clothing. There is a great deal of influence on quality and productivity by the clothing of the card. As a result of the development of new clothing, the card production rate was boosted from 5 kilograms per hour to current levels of up to 220 kilograms per hour, for example. In spite of the fact that new clothing was not the only factor in this increase, it played a significant role. However, the cost of this development has to be paid in the form of a steadily increasing departure from universal clothing, which was once a goal. The mill must make a difficult decision between hundreds of types of clothing, one that is of utmost importance to its success.

Selection of card clothing:

Selection of card clothing is depend on the following factors.

- Card type and design.

- Cylinder rotation speed.

- Productivity.

- Material flow.

- Type of raw material (natural or synthetic).

- Fiber characteristics (mainly fineness, length, bulk, dirt).

- Quality requirements.

- The clothing price.

- Clothing supplier service.

To know details about factors of selection of card clothing Click Here

Hundreds of variations of card clothing are currently available in all fields that use short-staple spinning mills. They can be divided into three categories.

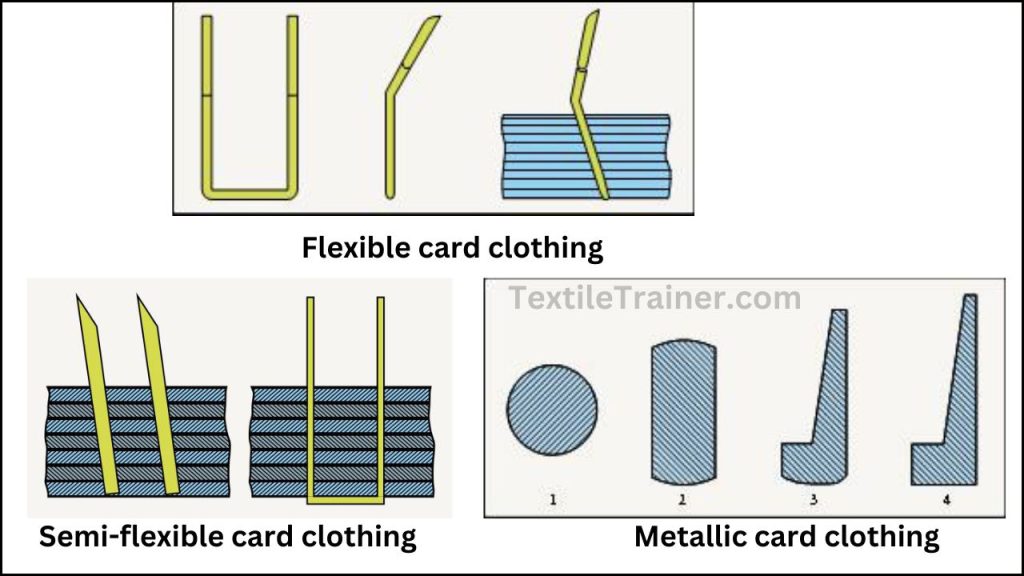

- Flexible card clothing: A continuous narrow band of cloth is formed for the main cylinder (51 mm), while a broad band (equal to the length of the flats) consists of five (flexible clothing), seven (semi-rigid clothing) or more layers joined together by vulcanization. In the substrate are two wire hooks embedded with a knee in one leg and a crossbar in the other. As a result, it is possible to operate with relatively small spacings between clothing surfaces since the hook does not project too far outward when the leg is bent back. In order to make the clothing more aggressive, the points are ground on both sides (lateral sharpening), and they are also hardened. On the flats, the point density varies from 240 to 500.

- Semi- flexible card clothing: The structure of this clothing is similar to that of flexible clothing. However, it has more cloth layers (pos- ably foamed material) and has hooks of square-section wire with or without a knee, or of reinforced round wire with or without a knee. It has the advantage of not clogging with fiber, thus eliminating flat strips, and requires less sharpening than flexible clothing types. It is important to note that each sharpening removes material from the tip of flat wires, so over time the working surface becomes steadily broader, and the clothing becomes less aggressive. It is possible to resharpen wire clothing only once or twice if it does not have lateral sharpening; with lateral sharpening, it can be sharpened four times.

- Metallic card clothing: These are continuous, self-supporting, square wire structures in which teeth are cut at the smallest possible spacings by a process resembling a punching operation in order to make them self-supporting. For example, the clothing of licker-ins, which has relatively large teeth, is referred to as saw-tooth clothing, which is the opposite of saw-tooth clothing. (There is no difference between saw-tooth clothing and metallic clothing.) In the present day, the licker-in, main cylinder and doffer all wear metallic clothing without exception.

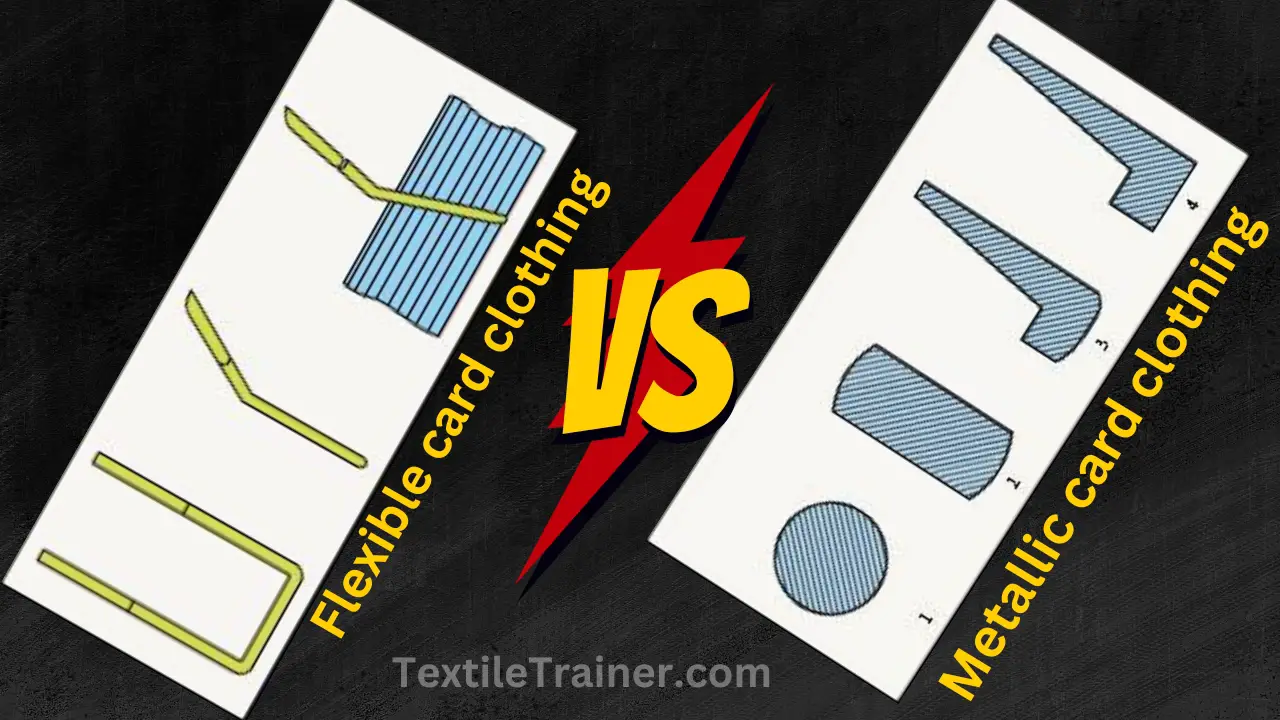

Differences Between Flexible and Metallic Card Clothing:

| S/N | Flexible card cloth | Metallic card cloth |

| 01. | Foundation material and card cloth of flexible card cloth are separate in formation. | Foundation material and card cloth of metallic card cloth are integral in formation. |

| 02. | Carding angle alter under strain. | Carding angle do not alter under strain. |

| 03. | Fibers chocks onto the bending zone. | Fibers don’t chock. |

| 04. | Degree of cleaning of flexible card clothing is low. | Degree of cleaning of metallic card clothing is higher. |

| 05. | Degree of action is comparatively gentle. | Degree of action is comparatively aggressive. |

| 06. | Replacement frequency is higher. | Replacement frequency is lower. |

| 07. | Lower working speed due to flexibility. | Faster working speed due to rigidity. |

| 08. | Teeth have knee or “U” shape. | No knee and “U” shape. |

| 09. | Frequency of grinding is high. | Frequency of grinding is lower. |

| 10. | Degree of opening is lower. | Degree of opening is higher. |

| 11. | Degree of unneping is low. | Nep is high. |

| 12. | Productivity of flexible card cloth is low. | Productivity of metallic card clothing is high. |

| 13. | Flexible card cloth has replacement flexibility e.i. only damaged part replaceable. | Complete set to be replaced. |

| 14. | Cost of flexible card cloth is low. | Cost of metallic card cloth is high. |

| 15. | It is used in flat card clothing. | Now-a-days, It is used in the licker-in, main cylinder and doffer without exception. |

You may read:

1 thought on “Best 15 Differences Between Flexible and Metallic Card Clothing”