10 Factors of Selection of Card Clothing for Best Carding Action

What is Card Clothing?

A card clothing is defined as a pin that is used to cover the surface of carding rollers and has a fine diameter, is spaced closely, and is bent in shape. Selection of card clothing is important task in case of carding machine. 10 most important factors of selection of card clothing will be discuss in this article. Card clothing is impact on the efficiency and effectiveness of the carding process, as well as the quality of the yarn that results, the design and quality of card clothing have a significant impact. The design and material of card clothing may vary according to the type of fiber and the processing requirements. There are three types of card clothing:

- flexible card clothing: The hooks are bent into a U-shape and have a knee that flexes under bending load, returning to its original position when the load is removed. They are set in elastic, multi-ply cloth backings with round or oval wire hooks. This clothing is now found only on card flats in short staple spinning mills. The point density is between 240 and 500 points per square inch on the flats.

- Semi-flexible card clothing: The structure of this clothing is similar to the flexible type, but with more layers and sharp points and squared cross sections. In addition to not clogging with fiber, it eliminates fewer flat strippings and requires less sharpening than flexible clothing types. Additionally, they are found only on flats.

- Metallic card clothing: As in a punching operation, teeth are cut at the smallest possible spacing by a continuous, selt-supporting, square wire structure. If the teeth are relatively large, such as in the licker-in, the clothing is referred to as saw-tooth clothing. Nowadays, metallic clothing is used without exception for the licker-in, main cylinder, and doffer.

Factors of Selection of Card Clothing

1. Type and Design of Card:

The selection of card cloth depends primarily on the type and design of card cloth, such as jute card, cotton card, and woolen card, for example.

2. Rotation Speed of the Cylinder:

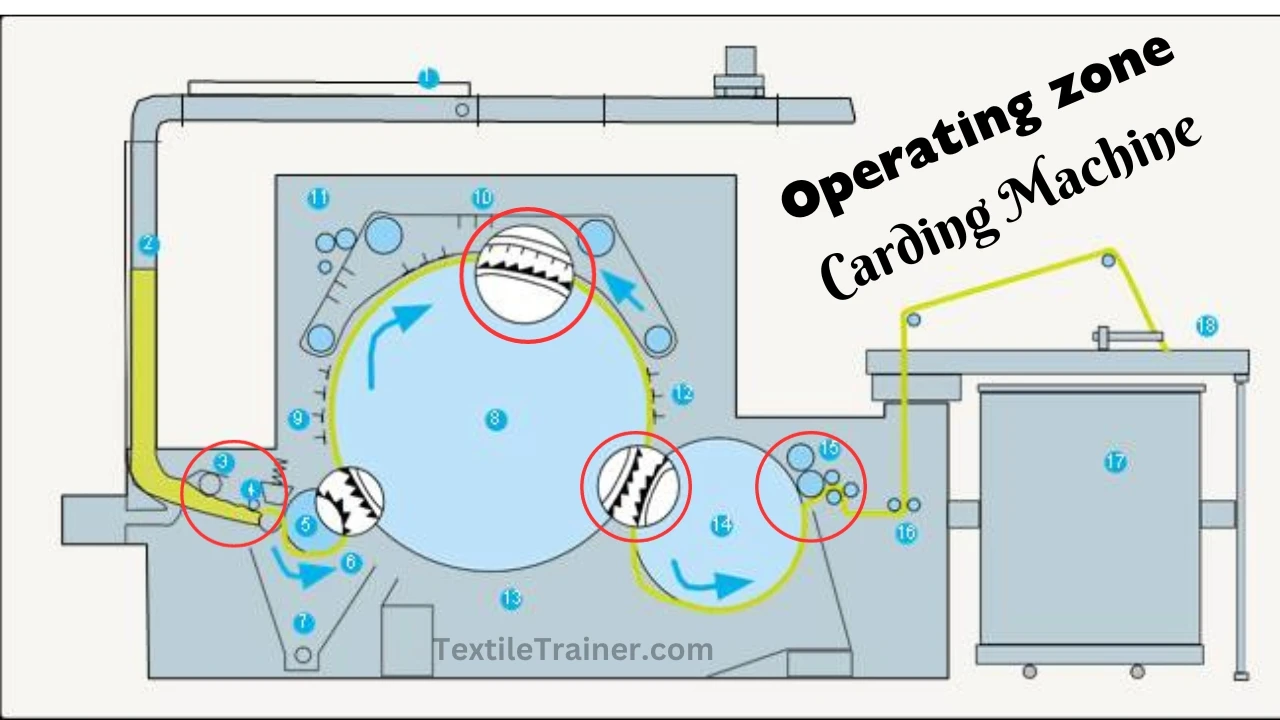

A cylinder surface is the main carding surface where fibers travel for longer distances and the fundamental carding action is carried out here, i.e. the level of signalization of fibers, the level of maximum cleaning, the orientation of fibers. In terms of cylinders to flats and cylinders to dots, the cylinder surface is active. In these three operating zones, all operations and actions are involved, so cylinder surface or momentum should be considered important. A cylinder clothing’s performance determines the degree of stressing, the amount of heat generated, the amount of cleaning, the amount of signalization, and the extent of unnepping. Therefore, the rotational speed of the cylinder dictates the choice of card clothing.

3. Degree of loading:

The degree of loading determines the service life of card cloth. It can be determined by the production rate of the material, that is, the amount of material treated per unit time by the card cloth. A high-performance card cloth is necessary for higher levels of loading.

4. Material throughput:

The selection of a cylinder clothing depends also on the material throughput of the card cloth. Cylinder clothing has a material throughput capacity ranging from 850 tons to 900 tons to 1050 tons and 1200 tons.

5. Raw material type:

The type of raw material can be determined by the type of card cloth to be used. For example, in the case of manmade fibers (polyester), low point density and low carding angle are recommended.

6. Fiber characteristics:

The type of card clothing to be selected depends on the characteristics of the fiber i.e. fiber fineness, length, bulk, dirt content.

7. Grade of Yarn:

There are different grades of yarn depending on the grade of card cloth to be selected. Here the grade of yarn refers to weaving grade yarn, knit grade yarn, denim grade yarn. For finer yarn we use long staple fiber and card cloth that has a higher point density.

8. Price of the clothing:

The price of clothing will contribute to the cost of the product. Therefore, the load life of the card cloth and thereby the cost of the product are the factors to be considered.

9. Service offered by the clothing supplier:

The type of card cloth to be selected will be determined by the technical service offered by the supplier.

10. Overall quality of Yarn:

There is a wide range of card cloth profiles that can be chosen based on the quality level of yarn.

You May Read More: