Introduction:

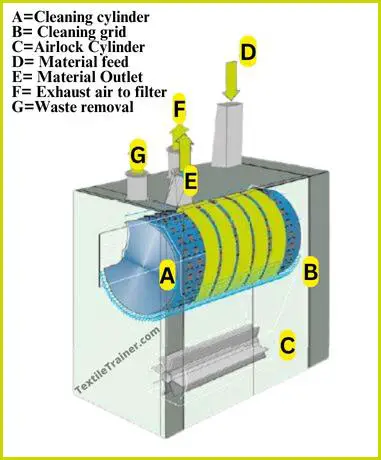

The Rieter Uniclean works in the coarse opening and cleaning zone. A basic function of this zone is to open the fiber tuft to smaller sizes and then to clean the tuft, removing large amounts of trash, but small amounts of impurities trapped between the fibers are not removed. This system uses rods or flexible pins to project from its surface (the beater) and grid bars below it to perform a gentle beating action. The system is used as a first cleaning stage for cotton tufts with a high trash content and therefore receives tufts from the automatic bale opener. Airflow is transported from the outlet to the inlet at a higher height, so small tufts are retained in the airflow and pass through the system without touching the beater because they are lighter in weight. The fiber loss is minimized as a result. The large tufts follow a spiral path around the beater to the outlet and make repeated contact with the projections on the rotating beater surface. The tufts are then struck against the grid bars to elect coarse trash particles.

Features of Rieter Uniclean:

The Rieter Uniclean is used for cleaning and preparing raw material, specifically fibers, in the textile industry. The Rieter Uniclean is used to remove impurities and trash particles from raw materials before further manufacturing steps like spinning and weaving. Its main purpose is to remove dust, fiber fragments, and other foreign substances present in the fibers. This ensures that subsequent manufacturing processes are not hampered and that final textile products meet quality standards by effectively cleaning fibers. There are some features that this machine has. Here are some of them:

- The Rieter Uniclean consists of a single beater with special pins of diverse sizes and angles, which give you a better clean.

- There is a large number of pins on the surface of the beater, making it ideal for intensive cleaning.

- There are five times that the material is mechanically passed over the cleaning grid.

- Dust, fiber fragments, and fine trash particles are mechanically removed from the machine by an integrated dust extracting filter (de-dusting unit).

- It is capable of removing heavy impurities and small trash, even from the smallest of tufts of hair.

- The speed range of the beater is 400 to 800 revolutions per minute.

- With teeth or spikes, the beater diameter is 750 mm.

- The working width of the machine is 1.6 meters.

- It is possible to produce up to 1200 kilograms per hour at this facility.

- The fiber package size has been converted from 10 grams to 0.1 grams.

Working Principle of Rieter Uniclean:

Rieter Uniclean is designed in a similar way to the monocylinder cleaner, in that there is an inlet duct(D), a large cleaning drum (A) with special hooks, a waste suction device, and an out-let duct (E). Instead of rotating three times inside the machine, it has to go over the grid five times, presenting new surfaces to the material every time it passes over the grid. It is not only the grid that is passed over by the tufts five times, but also the specially arranged perforated sheet five times over the grid. There is a low-pressure chamber behind this sheet. The air suction provided by the air suction through this sheet provides very efficient dedusting. The waste is collected inside the machine and fed to the waste transport via an airlock cylinder. A continuous suction system and intermittent suction are both possible. An airlock is used to prevent good fibers from being sucked through the grid during the removal of waste.

Conclusion:

In the textile industry, the Rieter Uniclean is essential for cleaning and preparing raw materials effectively. The machine ensures that yarns and fabrics are clean and free of impurities and trash particles. In the initial stages of fiber processing, the Uniclean is indispensable due to its advanced cleaning technology, dust extraction filter, and efficient specifications. The Rieter Uniclean contributes to the overall efficiency of textile manufacturing processes, ensuring the quality and integrity of products.

References:

- Chowdhury, M. F. (2016). Manual of Short Staple Spinning. Dhaka: Granthanir Prokashoni.

- Corbman, D. P. (1983). Textiles Fiber to Fabric. NewYork: Mary McGarry.

- Hossain, M. S. (2014). Introduction to Textile Engineering. Dhka: Books Fair Publications.

- Kadolph, S. J. (2006). Textiles. New Delhi: Dorling Kindersley India Pvt. Ltd.

- Rieter Manual for Spinning, Volume-II