What is dry process in Garments washing?

Dry process is the process which is applied to dry garments before first wash and sometimes after first wash. Usually, this process is applied to unwashed garments. It is the ornamentation of denim garments. Without a dry process, denim garments don’t look nice. This process is actually applied to denim garments. In this article, I will give a detailed description of every dry process in garment washing. I will also provide a list of the materials needed for the dry process in garment washing. Denim dry process creates many effects on denim fabric. Denim pry process creates extra value of garments washing. From this article, you can learn denim dry process of garments washing with proper image and description.

You may Read: How to Difference Between Knit Denim and Woven Denim Fabric with Easy 10 Point

List of Denim Dry Process of Garments Washing

There are different types of dry process of garments used in garment washing factory. Among all dry process in washing, here I listed some common denim dry process used in garments washing. They are:

- Hand sand

- Sand blast

- Whisker

- Destroy

- PP spray

- PP rubbing

- Tagging

- Grinding

- 3-D crinkle

- Tie

Now, I will describe all dry process in denim washing which is mention above.

1. Hand Sand

Now a days, hand sanding is an extremely important dry process. In this process, we do the work in dry conditions to remove the color from a specific area. Due to the ban on sand blasting, we have to do this for the majority of garments. Using abrasive paper, we manually scrub the garments on specific areas. After marking the garment, we put them on a dummy and scrapped them. Once this process is complete, quality check is done and the first wash is done. This process is clearly visible after the wash has been cleaned.

Material Need for Hand Sanding Process

- Emery paper

- Hand sand dummy

- Chalk for marking

Working Procedure of Hand Sand

- Marking the garments according to standard.

- Put into the hand sand dummy.

- Then scrapping the garments by emery paper.

- Finally, Check the quality.

2. Sand Blasting

It is also used to remove the color from the garments. This process is done using an air flow gun and sand. High pressure sand is applied directly to the garments in a specific area, reducing the color. However, this process has some disadvantages, so it has been banned now.

Material Need for Sand Blasting

- Sand blasting machine.

- Sand without containing iron

- Pattern board

- Air compressor

- N95 mask and ear plug for safety equipment.

- Marking chalk

Working Procedure of Sand Blasting

- The garments is marking according to the standard.

- Keep the garments on the machine surface.

- Then spray sand on the garments according to marking area.

- Finally, quality check.

3. Whisker

For denim garments, whiskering is the most important dry process. It involves creating a pattern and placing it in the garment, removing color from the pattern area, then washing the garment. We see the pattern markings after washing.

Material Need for Whisker

- Pattern board

- Emery paper

- Marking chalk

- Foam sheet

Working Procedure of Whisker

- At first, put the whisker pattern into the garments.

- Then rub the pattern area according to standard intensity by emery paper

- Quality check

4. Destroy

Destroy is a process which is done by a pen type grinding machine. First, we have to mark the garments then destroy the warp yarn by using pen types grinding machine. Then apply air to remove destroyed warp yarn. When garments are washed, they can take on a good destroyed appearance.

Material Need for Destroy

- Pen type destroy machine

- Marking chalk

- Pattern board

- Hand gloves for safety

Working Procedure of Destroy

- Marking the destruction place as per standard.

- Destruct the garments

- Apply air to remove broken warp yarn

- Check quality

5. PP Spray

A PP spray is a spray of potassium permanganate on clothing at a specific spot. We sprayed these chemicals to reduce color on the garments. To do this, we put the garments on a dummy, then take air, and then use air pressure to spray the PP gum. The spray was applied to the scrapping area, and after neutralizing, the area appeared white.

Material Need for PP Spray

- Spray gun

- PP solution

- Acetic acid or Phosphoric acid.

- Organic mask for safety.

Working Procedure of PP Spray

- Put the garments into dummy.

- Then spray the PP solution by PP gun.

- Quality check.

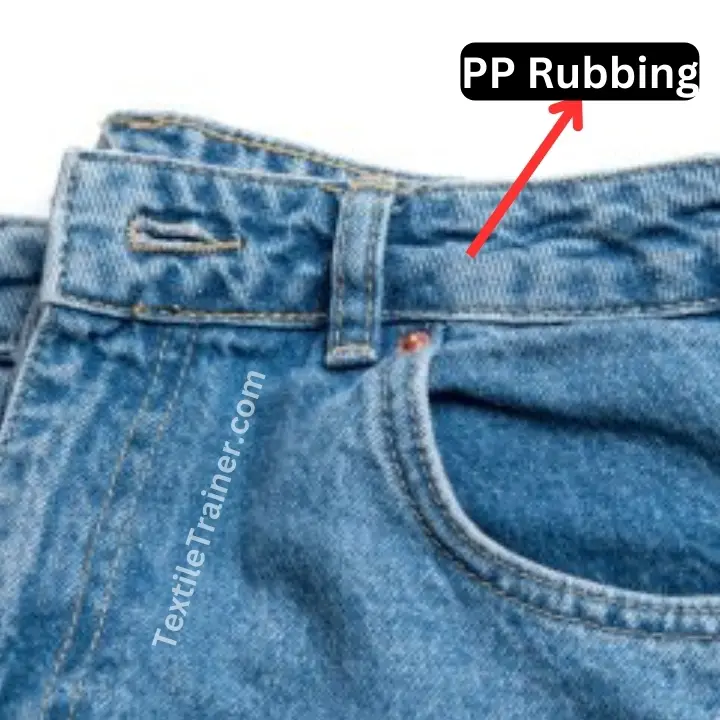

6. PP Rubbing

PP rubbing was sometimes used in order to get the effect, based on development requirements. By using this process, we get a more high-low effect. In the case of PP spraying, the effect will not be as high-low as in PP rubbing.

Material Need for PP Rubbing

- PP solution

- Phosphoric acid

- Sponge

- Dummy

- Hanger for hanging

- Hand gloves for safety.

Working Procedure of PP Rubbing

- Put the garments into the dummy.

- Rubbing PP solution by sponge.

- Dry the garments by hanging.

- Neutralization.

- Quality check.

7. Tagging

The process of tagging takes place when the garments are not yet washed. As soon as it has been washed, we will get it effect. Most of the time we will do it at the edge by folding the garments. This can be done with a tag gun, plastic staple machine or manually. This process sometimes damages the garments by creating holes.

Material Need for Tagging

- Tag gun

- Tag pin

- Chalk

- Hand gloves

Working Procedure of Tagging

- Marking the garments

- Fold the garments as per standard

- Then tag the garments

- Quality check.

8. Grinding

In this process, we will achieve a worn look for the garments. It is done completely on the edges of the garments. If the garment has been washed twice, then it is done after the first wash to avoid any damage to the garment.

Material Need for Grinding

- Grinding machine

- Hand gloves for safety

Working Procedure of Grinding

- At first, run the machine.

- Touching the edge of garments according to standard.

- Quality check

9. 3D crinkle

The 3-dimensional effect of crinkle is achieved by special treatments of garments. The process involves spraying resin on the 3-D area, creating 3D with the help of patterns, then curing the garments in the oven. In order to achieve the white effect, these garments are then washed in order to achieve the white effect.

Material Need for 3D Crinkle

- 3D machine

- Resin

- Spray gun

- White spray

Working Procedure of 3D Crinkle

- Apply the resin at 3D area.

- Put in the dummy.

- Make 3D crinkle as per standard.

- Pre cure the garments at 600 c for 1 min.

- Taken out the garments from machine.

- Put into curing oven for full cure.

- Quality check.

10. Tie:

Tie is an another dry process of garments washing. Tie create discontinuous line on the denim pant. These discontinuous line create vintage and old looking of denim pant.

Material Need for Tie

- Plastic rope

- Cutter

Working Procedure of Tie

- Tie is done before first wash.

- At first, tie the garments according to the standard with the help of plastic rope.

- Then, wash the garments.

- Sometimes, check the tie effect.

- If desired tie effect find, then cut the plastic rope.

Conclusion:

I have described the common denim dry process for garments washing above. If you have any doubts about different types of dry processes for garments washing, please let me know in the comments.

You may read:

- Top 15 Best Jeans Brands for Women in the World

- 20 Most Important Machine Used in Denim Washing Plant is Describe Easy way

- Best 10 Jeans Brands for Men in the world

- What is Garments Dyeing? Types of Garments Dyeing Machine Used in Garments Washing Plant

- 10 Most Important Difference between Denim and Jeans

- What is Denim? A Brief History of Denim is Described in Easy way-2023

- What is denim? 20 Different types of denim Fabrics are Described in Easy way

Thank you very much that you posted this processing, I love to read for increasing more about the washing standard.

Thanks for your comments. Please share my post in your social media and friends.