With the help of textile calculation, textile engineers, designers, and artisans can navigate the complexity of production confidently and accurately. Calculations underpin every aspect of textile production, from envisioning ideal fabric dimensions to optimizing material usage and anticipating textile behavior through multiple processes. sizing calculation is a one of the part of textile calculation. There is no doubt that sizing calculation plays a very important role in ensuring the quality and performance of fabrics in the world of textiles. It is the process of applying protective coatings to yarns or fabrics that enhance their strength, handle, and appearance through the application of a protective coating known as sizing, also known as sizing agent or textile sizing. There are many factors to consider when calculating the amount of sizing agent to be applied to the fabric, such as the fabric composition, weaving pattern, desired fabric properties, and intended end-use of the fabric. As part of this calculation, it is necessary to have a deep understanding of textile sciences, including fiber properties, yarn characteristics, as well as weaving techniques. in this article, I will present formula of sizing calculation. I also present lot of exercise which will be enrich you knowledge about sizing calculation.

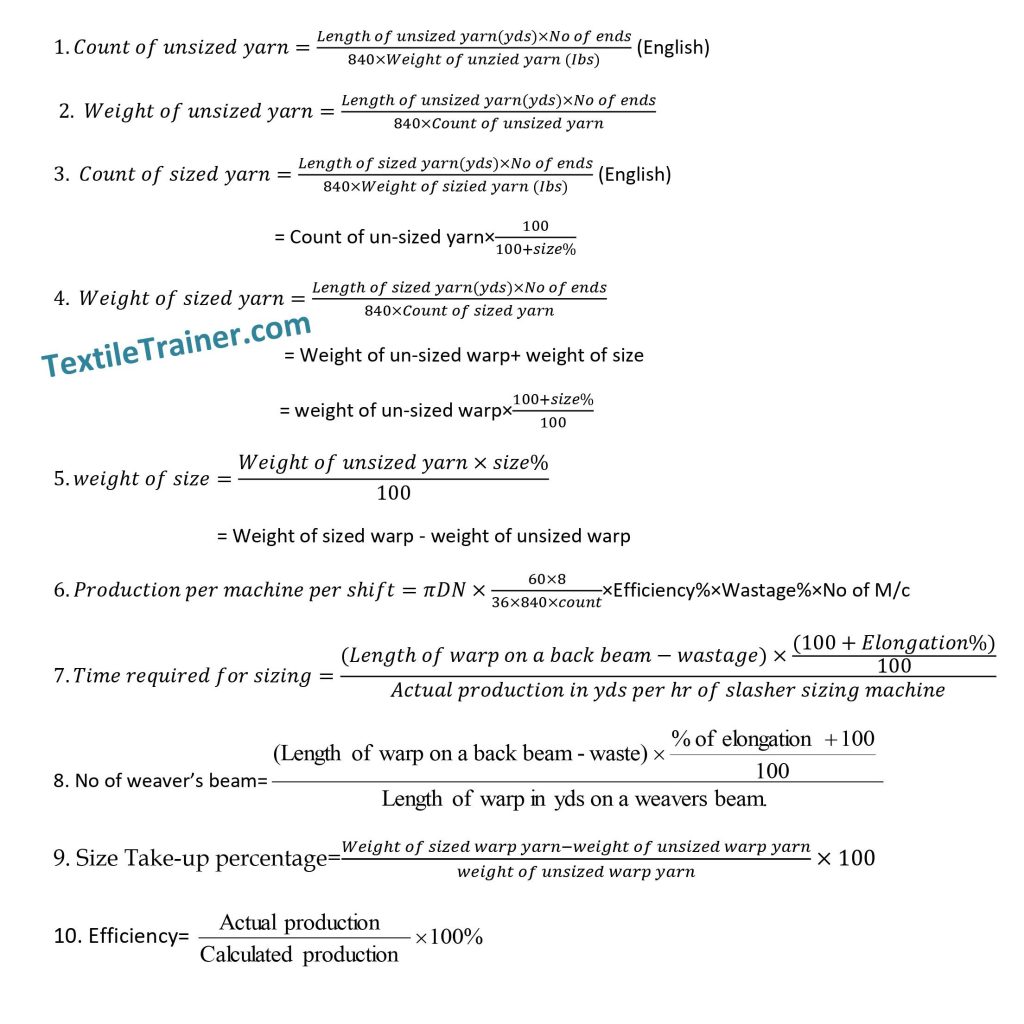

Formula for Sizing Calculation:

Exercise

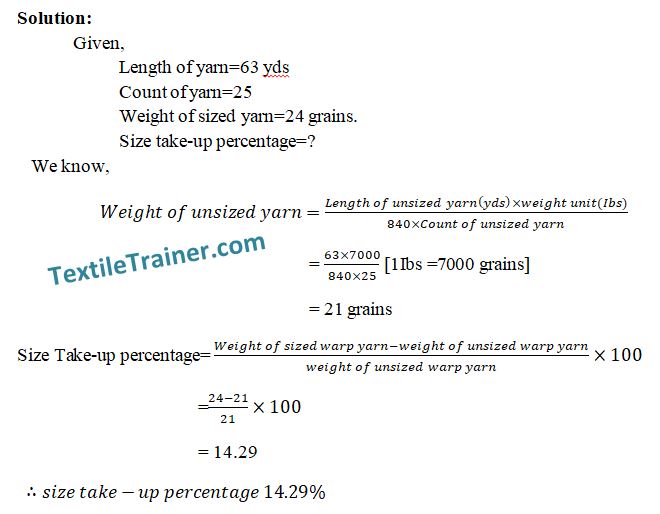

Exercise-1: After sizing 63 yds. of 25 count yarn, the weight was found 24 grains. Now calculate the size take-up percentage.

Exercise-2: After sizing 1050 yds of 50 count yarn, the weight was found 82.5 Ibs. If no of ends is 3000. Now calculate the size take-up percentage. [Self study, Answer: 10%]

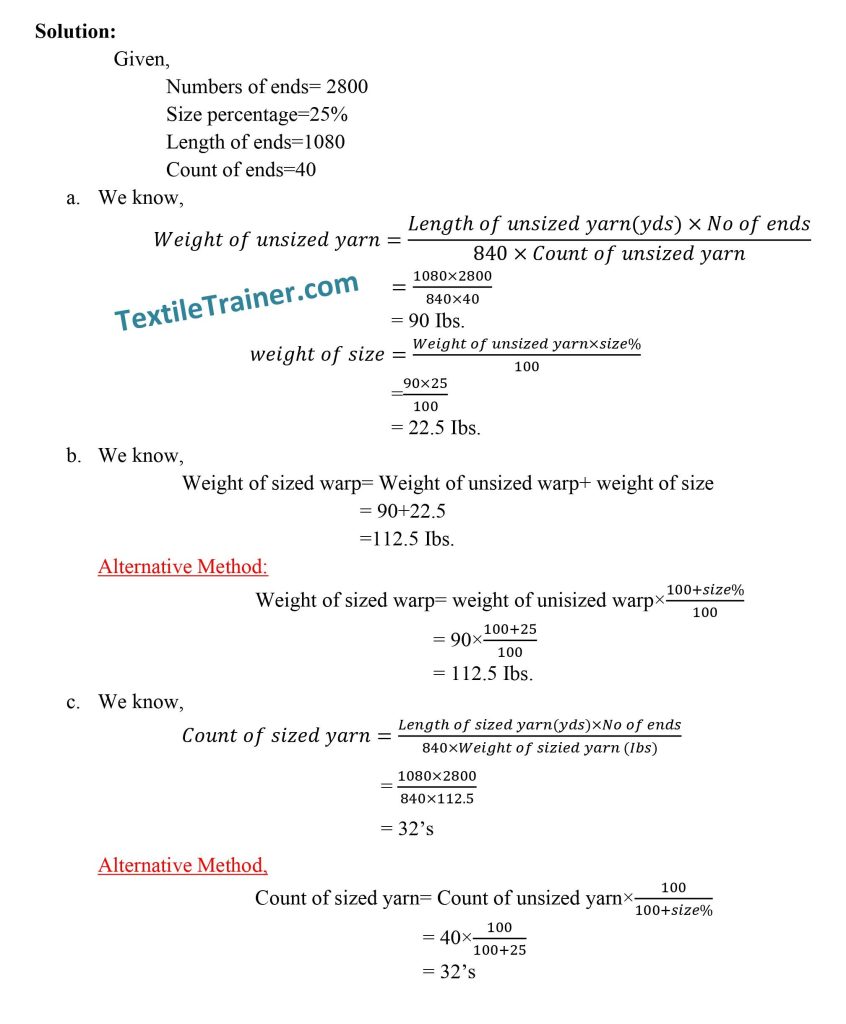

Exercise-3: A warp containing 2800 ends is required to be sized to 25%. The length of the sized warp on the beam is required to be 1080 yds. If the counts of the yarn are 40’s cotton, find-

- (a) The weight of size to be applied.

- (b) The weight of sized warp.

- (c) The count of the sized warp.

Exercise-4: the weight of sized yarn on a beam was found to be 77.5 Ibs. The beam contains 1045 yards of warp, whose count before sizing was 45’s cotton. If the number of ends in warp is 2500, calculate the following: [self study]

- The weight of size on the yarn. [answer-8.39 Ibs.]

- The size take-up percentage. [Answer- 12.14%]

- The count of sized yarn. [ Answer- 40’s]

Exercise-5: A warp containing 2400 ends of 44’s yarn is sized to 10%. If the size warp weight is 120 Ibs. Calculate the length of the sized warp, and the total length of sized yarn. [ self study, Answer: 2 hank or 1680 yds; 4800 hank or 4032000 yds respectively]

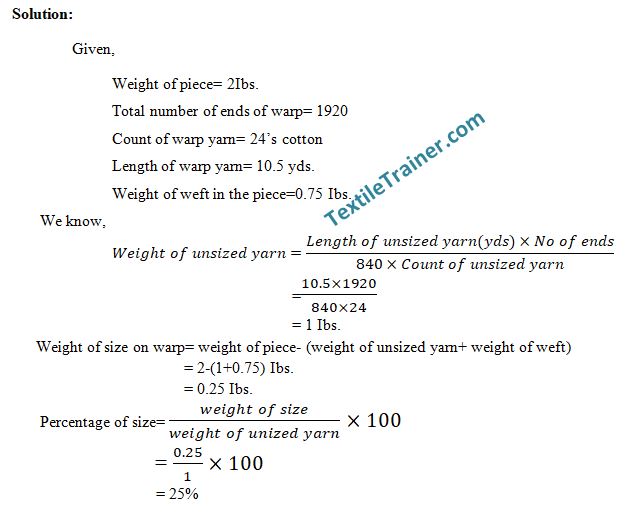

Exercise-6: A piece to be made of warp and weft of the following particulars, is required to weight 2 Ibs.

- Total number of ends of warp= 1920

- Count of warp yarn= 24’s cotton

- Length of warp yarn= 10.5 yds

- Weight of weft in the piece=0.75 Ibs.

Now calculate the weight of size and percentage of size required to be put on the warp yarn.

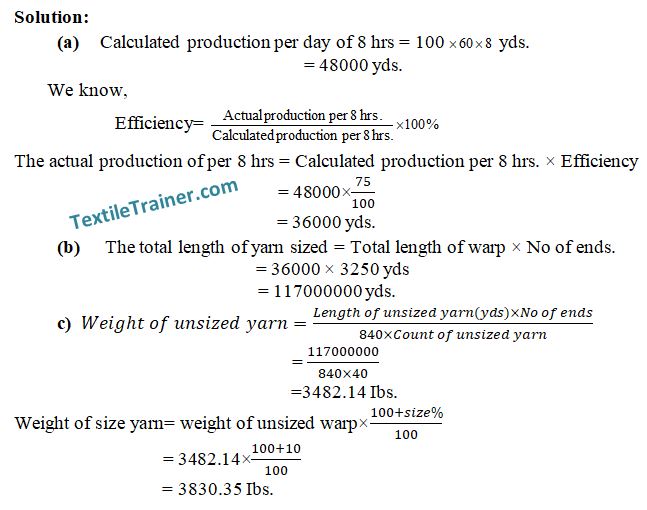

Exercise-7: The calculated production of a high speed slasher is 100 yds per min. If the efficiency of the machines is 75%. Calculate the followings:

- (a) The actual production per day of 8 hrs.

- (b) The total length of yarn if the total ends is 3250.

- (c) The total weight of the sized warp if it is sized to 10% and the count of unsized are 40’S.

Exercise-8: A beam of 250 kg contains sized yarn of 15% take up if the sized count 40.87’S. Calculate unsized count. [Self study, Answer-35.53’s]

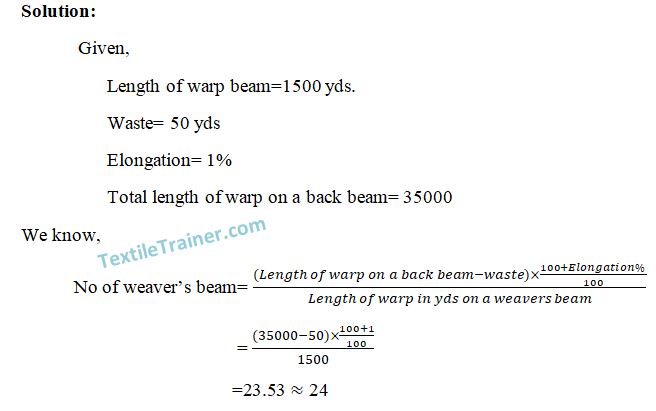

Exercise-9: A set of 10 beams each containing 35,000 yds. of warp is to be used for producing of weavers beams on a high speed slasher. If % of elongation is 1 % and waste of warp is 50 yds. Calculate the no of beams. The length of sized warp on a weaver is 1500 yds.

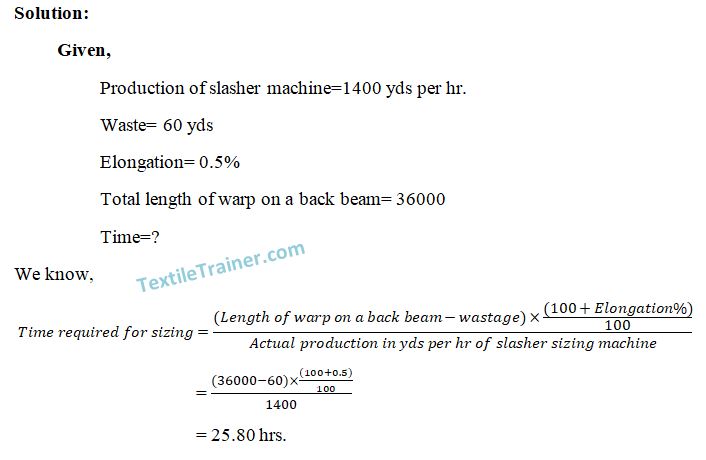

Exercise-10: The actual production of a high speed slasher is 1400 yds per hr. If % of elongation is 0.5%, waste of warp 60 yds. Time that would be required to size set of 6 back beams containing 36000 yds. of warp each.

Exercise-11: A set of 8 beams, each containing 40,000 yds of warp, is to be used for producing weaver beams on a high speed slasher sizing machine. Assume the elongation percentage is 1 % and the amount of waste warp is 40 yds. Calculate the number of beams. The length of sized warp on a weaver is 1300 yards. [Self study, Answer: 31]

Exercise-12: High speed slashers produce 1600 yards per hour. If elongation is 0.5%, waste of warp would be 45 yards. calculate Time required to size 6 back beams each containing 32000 yards of warp. [self study, answer- 20 hr]

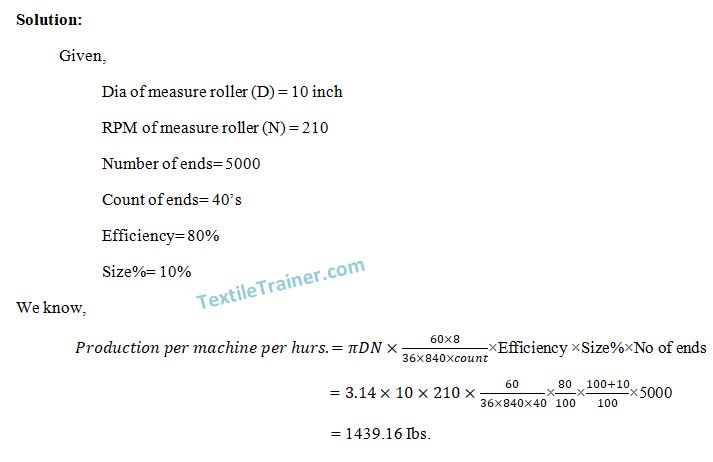

Exercise-13: Calculate the production of sizing machine per hour from the below date:

- Dia of measure roller= 10 inch

- RPM of measure roller= 210

- Number of ends= 5000

- Count of ends= 40’s

- Efficiency= 80%

- Size%= 10%

Exercise 14: Calculate the production of sizing machine per shift from the below date: [self study, Answer: 5514.34 Ibs per shift]

- Dia of measure roller= 8 inch

- RPM of measure roller= 200

- No of ends=6000

- Count of ends= 50’s

- Efficiency= 75%

- Size%= 12%

- Waste=1%

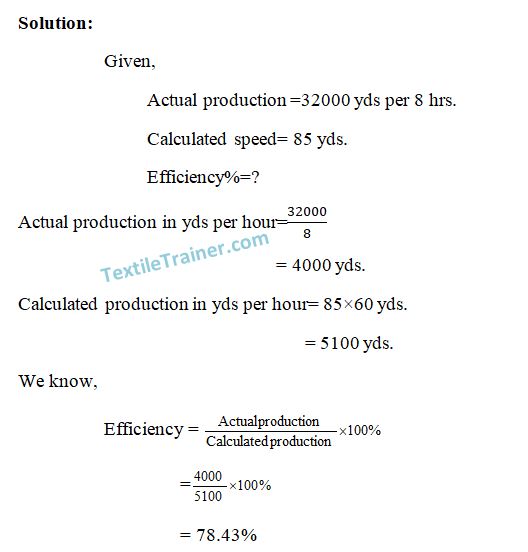

Exercise-15: The actual production of a high speed slasher machine is 32000 yds per day of 8 hrs. if calculated speed is 85 yds per min, find the efficiency.

In this article, I have tried my best to present sizing calculation with lots of exercises and all the mathematics problems have been collected from different books on textile calculation. If you have encountered any difficulties, please let me know with the comments. It will be my pleasure to assist you with your problem and I will try my best to do so.

You may read:

- Definitions of sizing, objectives and impact on warp yarn.

- Why sizing is called heart of weaving.

- Primary and Secondary Size Ingredients.

- Characteristics of Good Size Ingredients.

- Types and Techniques of sizing.

- Working Principle of Slasher Sizing Machine.

- Size Cooking Equipment.

- Drying Methods in Sizing Process.

- Modern Control System of Sizing Machine.

- Sizing faults

Reference:

- banerjee, N. (2000). Weaving Mechanism. West Bengal: Smt. Tandra Banerjee and Sri Apurba Banerjee.

- Gupta, R. S. (1977). Weaving Calculations . Bombay: D.B. Taraporevala Sons & Co. Private Ltd.

- Rahman, M. M. (2008). Fabric Manufacturing Technology. Dhaka: Books Fair Publications.

- V. Gordeev, P. V. (1982). Cotton Weaving. Russia: Mir Publishers Moscow.

1 thought on “Sizing Calculation: 10 Essential Formula for Accurate Calculation”