Slasher sizing machine is most commonly used and is suitable for large-scale operations. It involves assembling warp yarns into a continuous sheet, sizing them, and then wounding them onto weaving beams. Various auxiliary operations support these operations, such as separating ends, measuring warp lengths, marking into cut lengths, and winding the warp into an equal length to form the fabric’s warp. The tape sizing machine or slasher performs all of these operations. Slasher sizing machines are classified based on the drying method. They include the following three types:

- Cylinder drying: Twin and multi-cylinder type.

- Hot air drying.

- Electrical drying.

This method relies on the principle of conduction, which is widely used in industry. For drying sized warps in conventional machines, twin cylinders were used. However, multi cylinders have become more prevalent, and the second method uses the principle of convection, while the third method uses radiation to dry the warp.

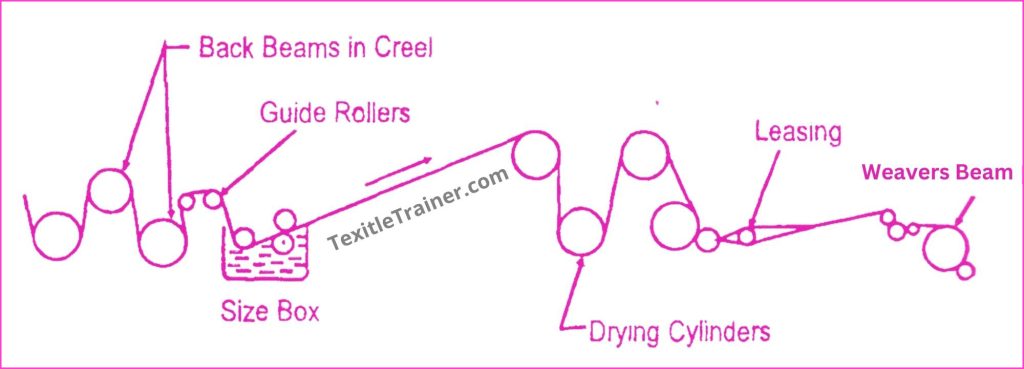

In summary, there are three important zones in the slasher machine, namely:

- Back beam & sizing unit: The rear or backside of the machine has a creel and size box.

- Drying and cooling unit: Drying arrangement forming the middle zone of the machine

- Weaver’s or size beam unit: The front zone or headstock consists of the weaver’s beam as well as various controls.

Working Principle of Slasher Sizing Machine:

- A guide roller is used to make the yarn pass into a size box from warper’s beams, which contain about 500-800 warp ends. Warper’s beams, also known as back beams, are placed in a creel stand. The number of warper beams depends on the number of ends required in the cloth or weaver’s beam. A warp passes over and under successive back beams from the rear beams. From the back beams, the warp sheet enters a size box heated by a continuous steam supply via pipes. The warp sheet passes under an immersion roller that is partially immersed and then between the size roller’s nips and the squeeze roller’s nips. By pulling the warp sheet through the paste, the squeeze roller impregnates the size into the yarn structure and removes external excess size.

- After being wet, the size yarn is dried in either a hot air chamber or two or more cylinders. The sized yarn is dried here. There is a regulated time in the drying zone for the sized warp to prevent over-dying. All cylinders are steam-heated with the exception of the last one, which is kept cool by cold water supply. When the warp sheet leaves the drying zone, this is done to cool it down.

- After leaving the drying zone, the warp yarns are split into as many sections or layers as there are beams in the creel. Using lease rods or split rods, the warp thread is split, thus eliminating stickiness between neighboring warp threads. After this, the split warp threads are recombined and then made to pass through an ‘expanding or zigzag’ reed or comb. The comb controls the width of the warp sheet to its required size. Next, the warp passes between the nips of a drag roller and is wound on a beam called a weaver’s beam or sizer’s beam.

Reference:

- Adanur, S. (2001). Handbook of weaving. Boca Raton: CRC press.

- banerjee, N. (2000). Weaving Mechanism. West Bengal: Smt. Tandra Banerjee and Sri Apurba Banerjee.

- Gandhi, K. (2012). Woven Textiles. New Delhi: Wood Publication Limited.

- Gokarneshan, D. N. (2009). Weaving Preparation Technology. Delhi: Abhishek Publicaions.

You May Read:

5 thoughts on “Passage of Materials Through a Slasher Sizing Machine is Described in Easy Way”