Innovation is key to staying ahead of the curve in the fast-paced textile manufacturing world. The weaving industry has undergone significant transformations due to the ever-growing demand for high-quality fabrics and efficient production processes. The revolutionary development in sizing technology promises to redefine fabric weaving as one of the latest breakthroughs. During weaving, the warp yarns are protected by a protective coating, known as size, prior to weaving. By coating the yarns, they become stronger and more resistant to abrasion, preventing them from breaking during the weaving process. Traditionally, sizing process has been a labor-intensive and time-consuming stage, limiting weaving’s overall efficiency. In this article, we explain the latest advancements in sizing technology that are set to revolutionize weaving. Its potential benefits are endless, from smart algorithms that optimize sizing formulations based on fabric specifications to advanced automated systems that precisely control the application of size. Additionally, this technology is intended to be adaptable to a wide range of fabric types, including delicate silk and rugged industrial textiles.

Development in Sizing Technology:

The purpose of this article is to discuss two types of latest developments in sizing technology for applying sizing materials to warp yarns.

- Cold and pre-wet sizing technology.

- Pre-wet sizing technology.

1. Cold and Pre-wet Sizing Technology

Cold size application on sample warps and short warps has been developed recently. It involves gently treating the warp surface without squeezing it. In comparison to waxing on sectional warpers, cold sizing produces better yarn compaction, a smoother surface, and less hairiness, which increases weaving efficiency. Cold size products from the suppliers can be used for cold sizing single yarn, siro yarns, two ply yarns, terry warps, and synthetic yarns. It is reported that the chemical products used are water soluble, recyclable, and biodegradable. The main advantages of this system include:

- Liquor pickup is low and liquor concentration is high.

- As compared to normal sizing, 30-50% less application is required.

- Energy savings in drying.

- There is less space on the machine.

- A higher level of modularity and productivity.

2. Pre-wet Sizing Technology:

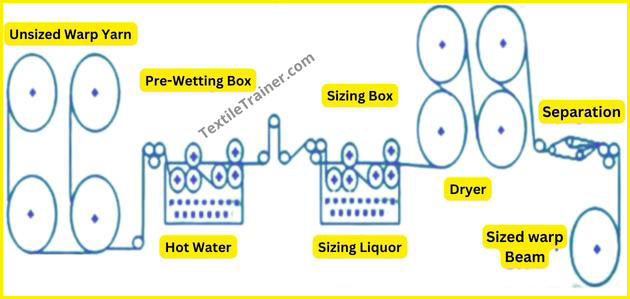

In another recent development, called pre-wet sizing technology, the yarns are soaked and washed in hot water before entering the size box. By doing this, it is claimed that size add-ons can be reduced by 20-40%, size adhesions are enhanced, abrasion resistance is increased, and hairiness is reduced. A better encapsulation of yarn by the sizing agent and a better adhesion of the sizing agent to the yarn contribute to improved weaving performance. This system has the following advantages according to preliminary results.

- Tensile strength increases by 15-19%.

- Hairiness is reduced by 50%.

- 70-200% increase in abrasion resistance.

- Reduction of clinging tendency.

- Lint formation during weaving is reduced by 30-50%.

Finally we can say, Fabric manufacturing has been transformed by advances in sizing technology, which has resulted in unparalleled efficiency and exceptional fabric quality. With these cutting-edge advancements, the industry is poised to achieve new heights, meeting the demands of modern consumers and businesses. Fabric production will become more innovative, sustainable, and precise with the continuous advancement of sizing technology.

You May Read:

- Definitions of sizing, objectives and impact on warp yarn.

- Why sizing is called heart of weaving.

- Primary and Secondary Size Ingredients.

- Characteristics of Good Size Ingredients.

- Types and Techniques of sizing.

- Working Principle of Slasher Sizing Machine.

- Size Cooking Equipment.

- Drying Methods in Sizing Process.

- Modern Control System of Sizing Machine.

Reference:

- Adanur, S. (2001). Handbook of weaving. Boca Raton: CRC press.

- banerjee, N. (2000). Weaving Mechanism. West Bengal: Smt. Tandra Banerjee and Sri Apurba Banerjee.

- Gandhi, K. (2012). Woven Textiles. New Delhi: Wood Publication Limited.

- Gokarneshan, D. N. (2009). Weaving Preparation Technology. Delhi: Abhishek Publicaions.

- stegmaier, T., Trauter, J., and wunderlich, W., “Reducing effluent loading in sizing and desizing”, Melliand internatinal

Great blog article.Thanks Again. Cool.

thanks too.

I think this is a real great article.Thanks Again. Great.

please support us.

Say, you got a nice article.Really thank you!

thanks too…

Im obliged for the blog post.Really looking forward to read more. Really Cool.

keep visit our site….

Really informative blog article.Thanks Again. Want more.

please share our article…

Looking forward to reading more. Great blog article. Will read on…

please support us.

I value the blog post.Really thank you! Keep writing.

keep visit our site…

A round of applause for your blog post.Much thanks again. Want more.

ok, I will try…

Im obliged for the blog article. Great.

please support us.

I appreciate you sharing this blog.Really looking forward to read more. Fantastic.

Keep visit our site….

Major thankies for the post.Thanks Again. Keep writing.

Thanks too

Greetings! Very helpful advice within this post! It is the little changes which will make the largest changes. Thanks a lot for sharing!

Thanks too

Really informative article. Awesome.

Thanks

Excellent article. Keep writing such kind of info on your blog. Im really impressed by your blog.

Thanks a lot

I’m extremely impressed with your writing skills and also with the layout on your blog. Is this a paid theme or did you customize it yourself? Anyway keep up the nice quality writing, it’s rare to see a great blog like this one today..

Very neat post.Really thank you! Fantastic.

Great, thanks for sharing this article. Will read on…

Very neat blog.

Awesome blog article.Thanks Again. Great.

keep visit our site…

I value the blog.Really looking forward to read more. Great.

keep visit our site…

Very informative blog.Really looking forward to read more. Really Great.

Wow, great post.Really thank you! Great.

Im obliged for the blog.Thanks Again. Fantastic.

Thanks for sharing, this is a fantastic blog article.Really thank you! Want more.

This was an awesome blog post. I loved it. I’ll be back to see more. Thanks .

I truly appreciate this article.Really looking forward to read more. Keep writing.

keep visit our site.

I really like and appreciate your blog article.Really thank you! Great.

keep visit our site.

Im thankful for the blog.Really thank you! Will read on…

keep visit our site.

Very good blog.Really thank you! Awesome.

Thanks too……

I really enjoy the blog post.Thanks Again. Really Great.

Say, you got a nice article.Really looking forward to read more. Really Cool.

Hey, thanks for the article post.Thanks Again. Cool.

please visit our site….

Really enjoyed this article post. Great.

Really informative post.Really looking forward to read more. Awesome.

Thanks. Stay connected

Hey, thanks for the article.Really looking forward to read more. Awesome.

I value the post.Much thanks again.

I think this is a real great blog post.Really looking forward to read more. Want more.

Thanks-a-mundo for the article.Really thank you! Really Cool.

Im obliged for the post.Really looking forward to read more. Awesome.

Very informative blog post.Much thanks again. Fantastic.

Really appreciate you sharing this article.Really thank you! Really Cool.

A big thank you for your article post.Really thank you! Keep writing.

Thanks so much for the blog post. Awesome.

Great blog. Much obliged.

Major thankies for the post.Thanks Again. Awesome.

I truly appreciate this post.Really looking forward to read more. Will read on…

A big thank you for your blog.Really looking forward to read more.

Im grateful for the article.Thanks Again.

Very informative article.Really thank you! Really Cool.

Enjoyed every bit of your post. Fantastic.

Say, you got a nice article post.Much thanks again. Really Great.

Say, you got a nice article post.Really thank you! Much obliged.

Very neat blog post.Much thanks again. Will read on…

Im grateful for the post.Really looking forward to read more. Great.

Very neat blog article.Much thanks again.

Great, thanks for sharing this blog article.Much thanks again. Keep writing.

Hi, I read your blog regularly. Your writing style is awesome, keep it up!

Thanks so much for the blog post.Much thanks again. Want more.

Welcome

Wow, great blog.Really looking forward to read more. Really Cool.

Thank you ever so for you article post.Much thanks again. Really Cool.

I really enjoy the article.Thanks Again. Will read on…

Looking forward to reading more. Great blog. Really Cool.

Thanks for the post.Thanks Again. Really Cool.

Thanks again for the article post.Thanks Again. Cool.

Really enjoyed this article post.Much thanks again.

Awesome blog.Much thanks again. Cool.

Very good blog.Really looking forward to read more. Fantastic.

I truly appreciate this article.Much thanks again. Really Cool.

Looking forward to reading more. Great article post.Much thanks again. Cool.

Thank you ever so for you blog post. Really Great.

Major thanks for the blog.

Enjoyed every bit of your blog article.Really looking forward to read more. Really Great.

Thanks so much for the blog.Really thank you! Really Cool.

Im thankful for the blog post.Really looking forward to read more. Fantastic.

Very neat blog post.Really thank you! Cool.

Say, you got a nice post.Much thanks again. Fantastic.

Major thanks for the blog.Really thank you! Want more.

Great blog article.Thanks Again. Much obliged.

I appreciate you sharing this article.Really thank you!

Say, you got a nice post.Really looking forward to read more. Fantastic.

This is one awesome article post.Much thanks again. Cool.

Thanks for the article. Fantastic.

Im grateful for the blog. Really Great.

I really liked your blog.Really looking forward to read more. Want more.

Really informative post.Really thank you! Awesome.

wow, awesome blog article.Thanks Again. Want more.

Great, thanks for sharing this post.Thanks Again. Want more.

This is one awesome article. Really Great.

Thanks for sharing, this is a fantastic blog.Thanks Again. Great.

Great article post. Much obliged.

Appreciate you sharing, great post.Really looking forward to read more. Really Great.

I really like and appreciate your blog.Really thank you! Keep writing.

I truly appreciate this post.Much thanks again. Keep writing.

Thanks for the article post.Thanks Again. Fantastic.

I truly appreciate this article.Really thank you!

wow, awesome blog article.Really looking forward to read more. Cool.

Hey, thanks for the blog.Much thanks again. Much obliged.

Thanks for sharing, this is a fantastic blog post. Fantastic.

I am so grateful for your post. Will read on…

This is one awesome post.Thanks Again. Keep writing.

I really like and appreciate your blog article. Want more.

Thank you ever so for you post.Really thank you! Will read on

I loved your blog article.Thanks Again. Great.

Very good blog article. Really Cool.

Wow, great article.Much thanks again. Cool.

Fantastic article.Much thanks again. Keep writing.

Im thankful for the blog.Really thank you! Cool.

Thanks for the blog article.Really looking forward to read more. Fantastic.

Im thankful for the article.Really looking forward to read more. Really Cool.

Thank you ever so for you blog post. Much obliged.

Hey, thanks for the post. Keep writing.

A big thank you for your blog article.Really looking forward to read more. Awesome.

Pretty element of content. I just stumbled upon your weblog and in accession capital to assert that I get in fact loved account your weblog posts. Anyway I will be subscribing to your augment and even I achievement you access consistently rapidly.

Thanks

Attractive section of content. I just stumbled upon your blog and in accession capital to assert that I get actually enjoyed account your blog posts. Anyway I’ll be subscribing to your augment and even I achievement you access consistently fast.

Thanks

Thanks for sharing, this is a fantastic blog. Great.

Great post.Really thank you! Much obliged.

Thanks

Really appreciate you sharing this blog. Want more.

Great article. Fantastic.

Hey, thanks for the article post.Really looking forward to read more. Fantastic.

Very informative post.Thanks Again. Will read on…

Wow! This blog looks exactly like my old one! It’s on a entirely different topic but it has pretty much the same layout and design. Superb choice of colors!

Thanks

Really informative article post.Thanks Again. Much obliged.

Thanks for the article.Much thanks again. Great.

Thank you ever so for you article.Much thanks again. Awesome.

Wow, great blog post.Really looking forward to read more. Much obliged.

Thanks for the blog.Thanks Again.

I really enjoy the post.Thanks Again.

Really informative blog article.Much thanks again. Keep writing.

Awesome blog post.Thanks Again. Really Cool.

I really enjoy the post. Really Great.

Thanks again for the blog.Much thanks again. Want more.

Awesome article.Much thanks again. Cool.

I really liked your blog article.Really looking forward to read more.

Great article post.Really thank you! Great.

Thanks so much for the blog post. Really Great.

Great blog.Thanks Again. Keep writing.

I think that is among the such a lot important info for me. And i am satisfied reading your article. But want to remark on some basic issues, The website taste is great, the articles is in reality nice : D. Excellent task, cheers

I need to to thank you for this very good read!! I certainly loved every little bit of it. I have got you saved as a favorite to check out new stuff you post…

Thanks

Im thankful for the blog post.Thanks Again. Want more.

I appreciate you sharing this blog article.Thanks Again. Awesome.

Really appreciate you sharing this blog.Much thanks again. Fantastic.

Very informative article post.Really looking forward to read more. Keep writing.

Wow, great article.Thanks Again. Great.

Thank you for sharing indeed great looking !