In this article, I will briefly describe size cooking equipment. The preparation of size paste is a crucial aspect of sizing, as it has a direct bearing on the quality of the sized warp sheet. During the preparation of size paste, particularly when starch is used, proper care and caution must be exercised. It is important to prepare the size paste or mixture correctly after selecting the ingredients. The sequence and temperature of adding size ingredients, as well as the duration of sizing, need to be properly controlled, otherwise the purpose of sizing is lost.

Size Cooking Equipment:

It has been developed over the years that there are various sizes of cooking equipment. The following are some of the types of size cooking equipment.

- Size cooking kettles.

- Homogenisers

- Pressure cookers

- Injection cookers

- High shear size mixing equipment.

Now, I will brief describe above mentioned size cooking equipment.

1. Size Cooking Kettles:

These are also known as the becks. They are the simplest and most conventional types of cooking vessels. A beck is a vessel made of wood and shaped cubically with each side measuring 1.25 meters. A storage beck is included as well. The cooking beck is provided with a stirrer at its center that is driven by bevel wheels on a shaft, which in turn is driven by a line shaft or by an individual motor through reduction gearing. The cylindrical becks were then developed in order to prevent corrosion of the cast iron. Sometimes, becks were also made of pure copper. However, these were more expensive. There is an advantage to cylindrical becks over cubically shaped ones in that the stirrers can reach all parts of the beck, whereas in cylindrical becks, the stirrers will not be able to reach the four corners. Steam pipes are attached to the mixing becks, alongside the stirrers, for heating. The size mixing becks range in capacity from 675 to 1800 liters.

2. Homogenisers:

During continued boiling and stirring of the cold size paste (slurry), the swollen starch granules burst out to uneven sizes and thus the viscosity of the size paste is unstable. A paste of this size is easily affected by changes in temperature as well as storage. Size films are also not uniform. Hornogenisers are equipment that breaks down swollen starch granules into smaller particles that have more or less uniform sizes. During homogenisation, the cold starch slurry is heated to just above the gelatinizing temperature of the particular starch, improving the stability and uniformity of the size paste. The starch paste containing the swollen but unbroken granules is then passed through a small hole of microscopic dimensions with such great force and speed that the swollen granules rub against one another and against the wall of the hole, and become more or less uniform in size. It is thus easier to make paste that has a higher viscosity, and it forms a more uniform film on yarn. Homogenisers were popular until very recently.

3. Pressure Cookers:

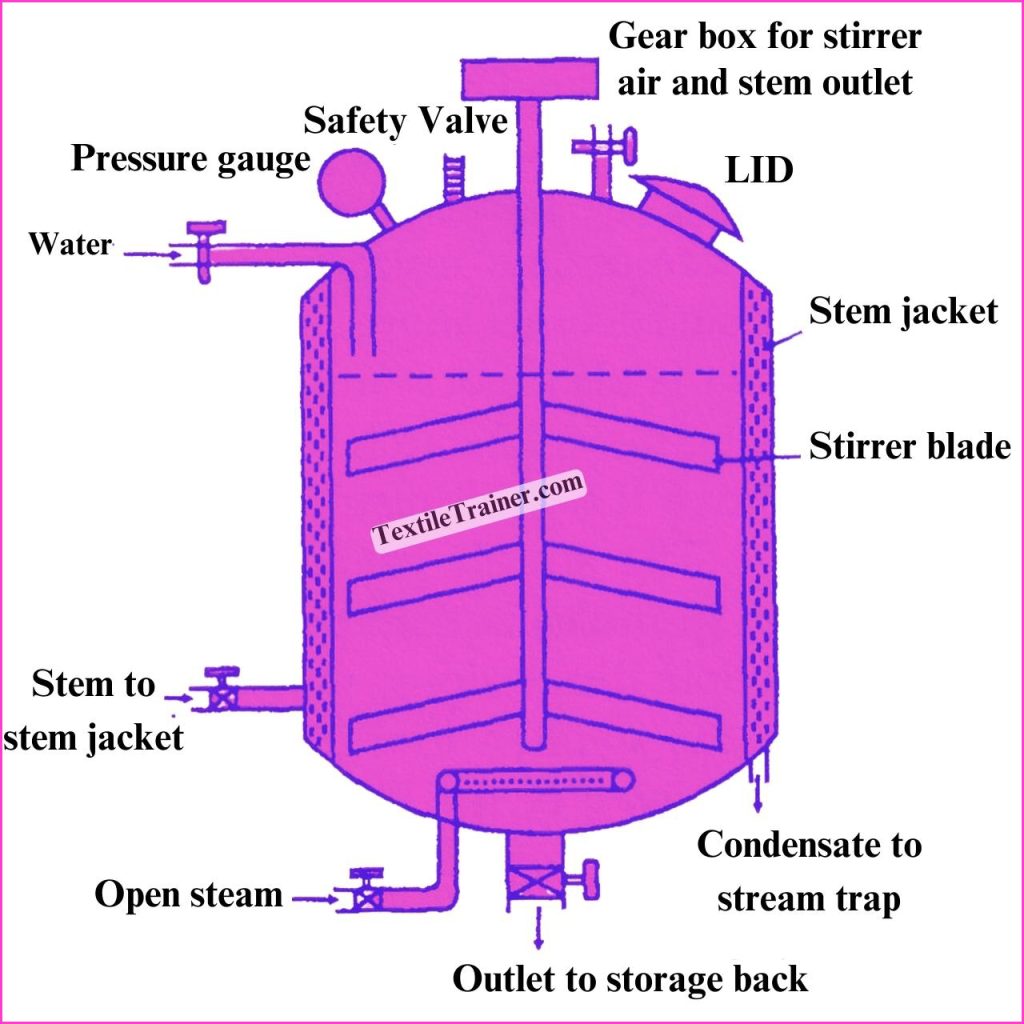

With pressure cookers, cooking time is reduced and steam consumption is reduced. A stirrer is placed at the center of the cooker and rotates at a speed of 40-60 rpm. The cooker is cylindrical in shape and has a diameter of 1.25 m x 1.5 m overall. The cooker is equipped with a safety valve as well as steam and water inlet and outlet pipes. Temperature control is available. The volume of water (containing adhesive) taken is slightly less than the final volume. The stirrer is started and steam is let into the steam jacket. Upon the beginning of boiling, the lid is closed, steam is stopped entering the cooker, and steam pressure is increased to 1.5 bar. Once the cooking has been completed for half an hour at the ideal temperature, the pressure is allowed to drop and the size mixture is transferred to the storage tank. This is when ingredients such as antiseptic, softener, etc are added to the size mixture and the mixture is boiled.

4. Injection Cookers:

There are two types of injection cooker: the pressure cooker and the homogeniser. Injection cookers are a modified version of pressure cookers and act as an intermediate between pressure cookers and homogenisers. The size mixture is pushed upward and forced into a pipe mixer inside the cooking vessel by a centrifugal pump that’s mounted beneath the cooker. During the mixing process, the size mixture is forced into the cooking vessel through slots at the bottom of the size mixer pipe. Pressurized steam is also injected into the pipe mixer to push the size mixture down. The injected steam creates a small pressure in the size mixture due to the centrifugal pump pressure. Mechanical agitation takes place due to the high flow rate of the size mixture and the injected steam, accompanied by high temperatures. Starch granules swell quickly and then burst, thereby reducing the cooking time to one third of the usual amount of time, thereby reducing steam consumption significantly. A device measures the viscosity of the size mixture in the cooking vessel. The centrifugal pump forces the ready size paste into the storage vessel once the viscosity level reaches the optimum value. Once the steam supply is shut off and the third opening of the valve in the size circulation passage is opened, the steam supply is shut off, and the third opening of the valve in the size circulation passage is opened.

5. High Shear Size Mixing Equipment:

The homogenizer has proven to be effective for producing a good quality of size paste with uniform size film. It is necessary, however, to have a very powerful circulating pump in this case. It is therefore necessary to use high shear cooking equipment of various kinds to achieve the above goals. These equipment are said to have a number of advantages, including:

- There has been a considerable reduction in steam consumption

- It takes less time to prepare size paste

- The size paste penetrates the warp better due to its lower viscosity

- Due to the uniformity of size film, weaving efficiency is improved

- A reduction in ingredient size results in a reduction in cost

Many high performance cooking equipment are based on this principle, including the zell-o-mat cooker, platt high shear mixer, sucker turbo mixer, and hibbert’s rapisonic homogenizer.

Reference:

- Adanur, S. (2001). Handbook of weaving. Boca Raton: CRC press.

- Gandhi, K. (2012). Woven Textiles. New Delhi: Wood Publication Limited.

- Gokarneshan, D. N. (2009). Weaving Preparation Technology. Delhi: Abhishek Publicaions.

- V. Gordeev, P. V. (1982). Cotton Weaving. Russia: Mir Publishers Moscow.

You May Read:

9 thoughts on “5 Types of Size Cooking Equipment for Successful Sizing Process”