What is Size Take Up Percentage?

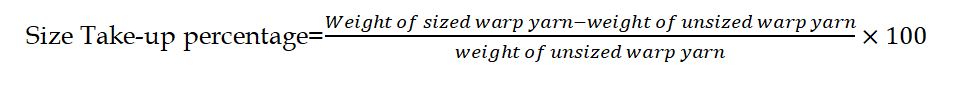

Size Take-Up Percentage plays a crucial role in the quality and performance of finished products in textile manufacturing and weaving. This essential metric refers to the quantity of sized materials added to the warp yarn surface, expressed as a percentage. This is a measure of the amount of sized materials that have been added to the warp yarn surface, often expressed as a percentage. Size take up percentage can be calculated by below formula.

Factors affecting the size take up percentage:

There are lots of factors that affecting the size take up percentage. Among those, here are discussed some common factors. They are:

- Fiber characteristics: Size Take-Up Percentage is significantly influenced by the type and quality of fiber. With cotton fibers, immature fibers with larger lumens tend to result in higher Size Take-Up Percentages. However, mature cotton fibers with smaller lumens tend to show lower Size Take-Up Percentages due to their reduced capacity to absorb size.

- Wet ability: The wet ability of fibers or yarns is another vital factor affecting the Size Take-Up Percentage. During the sizing process, yarns with higher wet ability tend to pick up a larger size. An effective ability to absorb liquids or moisture is the ability of a material to absorb moisture.

- EPI: The EPI, or ends per inch, is a measure of the number of warp yarns that make up a woven fabric. A higher EPI value leads to a higher Size Take-Up Percentage.

- Yarn characteristics: In the sizing process, yarn characteristics have a significant impact on Size Take-Up Percentage. One of the most crucial aspects is yarn hairiness. Yarns with higher hairiness typically have a higher Size Take-Up Percentage. As a result of the increased presence of protruding fibers on the yarn surface, sizing materials are better entangled, resulting in a greater size pick-up.

- Warp tension: Size Take-Up Percentage is affected by the tension of warp yarns during the sizing process. Higher tension in the yarns results in a lower size pick-up percentage.

- Linear density: The linear density or yarn count refers to the thickness or fineness of the yarn. Coarser yarns have a higher Size Take-Up Percentage, meaning they can absorb more sizing materials during the sizing process. The smaller diameter of finer yarns results in a lower Size Take-Up Percentage, so they are less able to hold sizing materials.

- Roller diameter: The diameter of squeezing rollers also influences the Size Take-Up Percentage. The diameter of squeezing rollers facilitates more effective penetration of sizing materials into yarn, so larger squeezing roller diameters lead to a higher Size Take-Up Percentage. Conversely, smaller squeezing roller diameters result in a lower Size Take-Up Percentage due to limited penetration.

- Contact length in size: Increasing the contact length of yarn with the sizing material increases the Size Take-Up Percentage, since more yarn surface area is exposed to the sizing materials, resulting in greater absorption and retention.

- Size concentration: A higher concentration of sizing materials used in the sizing process results in a higher Size Take-Up Percentage, as more sizing material is available for absorption and retention by the yarns.

- Preparation condition: Size Take-Up Percentage depends on the shape and condition of sizing materials. Finer and correctly prepared sizing materials lead to more consistent and effective absorption by yarns.

- Uniformity of warp yarn: Size Take-Up Percentage directly relates to the uniformity of warp yarns. If the warp yarns are uniform, the size take-up percentage is lower, while if the warp yarns are un-uniform, it is higher. As a result of uniform yarns, sizing materials can be distributed and absorbed more evenly, leading to a more consistent, controlled Size Take-Up Percentage. Conversely, irregular or un-uniform yarns can cause sizing to be distributed unevenly, resulting in a higher Size Take-Up Percentage.

- Roller Weight: In the sizing process, the pressure exerted by the squeezing rollers has an impact on the size pick-up percentage. Higher squeezing roller weight results in a higher percentage of yarn penetration of sizing materials.

- Nature of roller covering: The surface characteristics of the size roller play a crucial role in the Size Take-Up Percentage. A rough and soft surface on the roller enhances the Size Take-Up Percentage, as it allows for better adhesion and retention of sizing materials onto the yarns, which leads to enhanced weaving efficiency.

- Running speed: Size Pick-Up Percentage is determined by the running speed of the sizing process. Higher running speeds result in a lower size pick-up percentage since the absorption process is limited by the shorter contact time between yarn and sizing material.

- Ingredients: The Size Take-Up Percentage can vary based on the type of sizing material and its adhesive properties. For example, starch has a greater adhesive power than flour, resulting in a different size pick-up percentage.

You may read:

- Definitions of sizing, objectives and impact on warp yarn.

- Why sizing is called heart of weaving.

- Primary and Secondary Size Ingredients.

- Characteristics of Good Size Ingredients.

- Types and Techniques of sizing.

- Working Principle of Slasher Sizing Machine.

- Size Cooking Equipment.

- Drying Methods in Sizing Process.

- Modern Control System of Sizing Machine.

- Sizing faults

Really enjoyed this article.Really thank you!