What is Yarn Guide?

A yarn guides is a device used in the textile industry to help guide yarn or thread through textile machinery. It is a small component mounted onto the equipment and guides the yarn through various stages of the manufacturing process. The yarn guide helps to ensure that the yarn is tensioned correctly and controlled, which helps to prevent breakages and other problems during the manufacturing process. There are various types of yarn guides in textile industry used, each designed for different applications and types of yarns, and they can be made from other materials such as metal, ceramic, or plastic.

In fabric manufacturing, a yarn guide is a device used to guide yarn during the manufacturing process. The yarn guide is essential to weaving machines, knitting machines, and other textile manufacturing equipment. The primary purpose of a yarn guide is to ensure that the yarn is fed smoothly and evenly through the manufacturing process. This is important because variations in the tension or placement of the yarn can lead to defects in the finished fabric.

Important of Yarn Guides:

The yarn guide is an essential component of textile manufacturing equipment and plays a crucial role in ensuring the quality and consistency of the finished fabric. Here are some of the reasons why the yarn guide is so essential:

1. Consistent tension:

The yarn guide helps to maintain a consistent tension in the yarn as it is fed through the manufacturing process. This is critical for producing a uniform fabric in texture and appearance.

2. Even feeding:

The yarn guide helps to ensure that the yarn is provided evenly through the manufacturing process. This prevents uneven fabric density or pattern distortion.

3. Reduced waste:

When the yarn is fed evenly through manufacturing, there is less waste due to yarn breakage or snarls.

4. Increased productivity:

A well-designed yarn guide can help to increase productivity by reducing downtime due to yarn breaks or other manufacturing issues.

5. Improved quality:

By maintaining consistent tension and even feeding, the yarn guide helps to produce a high-quality fabric that meets the desired specifications.

6. Reduced machine wear and tear:

The yarn guide helps to protect the machine from excessive wear and tear. By guiding the yarn smoothly and evenly, the guide helps to prevent damage to the machine parts that come into contact with the yarn.

7. Flexibility:

A well-designed yarn guide can accommodate a wide range of yarn types and sizes, allowing textile manufacturers to work with various fabrics and materials.

8. Precision:

The yarn guide can be adjusted to provide precise tension and feeding, allowing textile manufacturers to achieve particular fabric characteristics, such as stretch, texture, or pattern.

9. Cost-effective:

By reducing waste, increasing productivity, and improving quality, the yarn guide helps to make textile manufacturing more cost-effective.

10. Improved worker safety:

Properly maintained yarn guides can help to prevent accidents and injuries caused by yarn breaks or snarls, which can lead to entanglement, falls, or other hazards.

The component of yarn guide made from:

Yarn guides are typically made from materials that are resistant to wear and tear, such as ceramic, hardened steel, or plastic. The choice of material depends on a range of factors, including the type of yarn being used, the speed of the manufacturing process, and the conditions under which the equipment operates. Ceramic yarn guides are commonly used in high-speed textile manufacturing processes, such as in producing synthetic fibres or fabrics. Ceramics is a hard and durable material that can withstand the high speeds and friction generated during manufacturing. Ceramic guides are also highly resistant to wear and tear, making them a good choice for long-lasting, high-performance applications. Hardened steel yarn guides are also used in high-speed manufacturing processes, particularly for heavy-duty applications that require greater strength and durability. Steel guides are typically made from a type of hardened alloy steel that can withstand high temperatures and the rigours of continuous operation. Plastic yarn guides, such as cotton, wool, or other natural fibres, are commonly used in low-speed textile manufacturing processes. Plastic guides are lightweight, easy to manufacture, and relatively inexpensive, making them a popular choice for applications that require flexibility and adaptability.

Overall, the choice of material for a yarn guide depends on a range of factors, including the specific needs of the manufacturing process, the type of yarn being used, and the conditions under which the equipment operates.

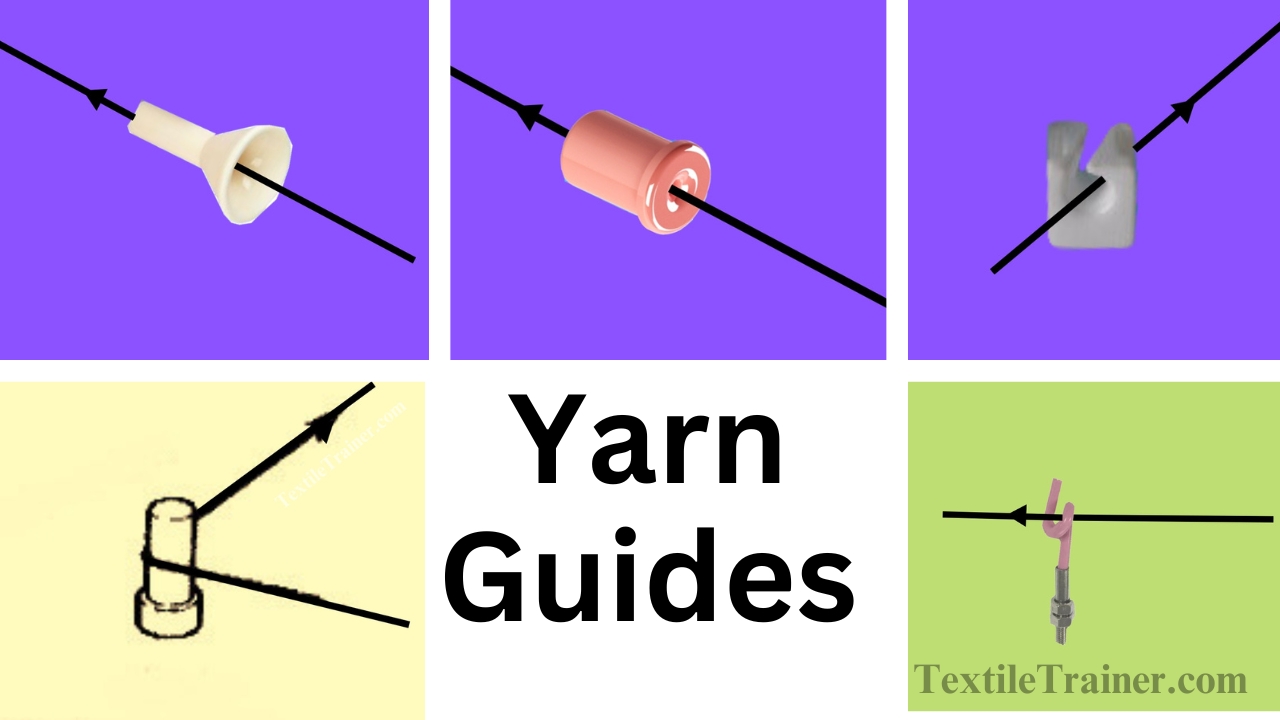

Types of Yarn Guides

Basically, there are two types of yarn guides used in textile industry specially in fabric manufacturing. They are:

- Type-A: Closed yarn guides (A yarn end is required for threading)

- Type-B: open yarn guides ( A yarn end is not required for threading)

1. Type-A: Closed Yarn Guides:

A closed yarn guide is a type of yarn guide used in textile manufacturing equipment that helps to guide the yarn through the manufacturing process. Unlike an open yarn guide with a gap or opening through which the yarn passes, a closed yarn guide completely encloses the yarn as it is fed through the guide. Closed yarn guides are commonly used in high-speed textile manufacturing processes, such as in producing synthetic fibers or fabrics. They are often made from materials that are resistant to wear and tear, such as ceramics or hardened steel, to withstand the high speeds and friction generated during the manufacturing process.

Closed yarn guides may classified into three. they are:

- Ceramic Insert Type Yarn Guide.

- Trumpet Type Yarn Guide.

- Bush Type Yarn Guide.

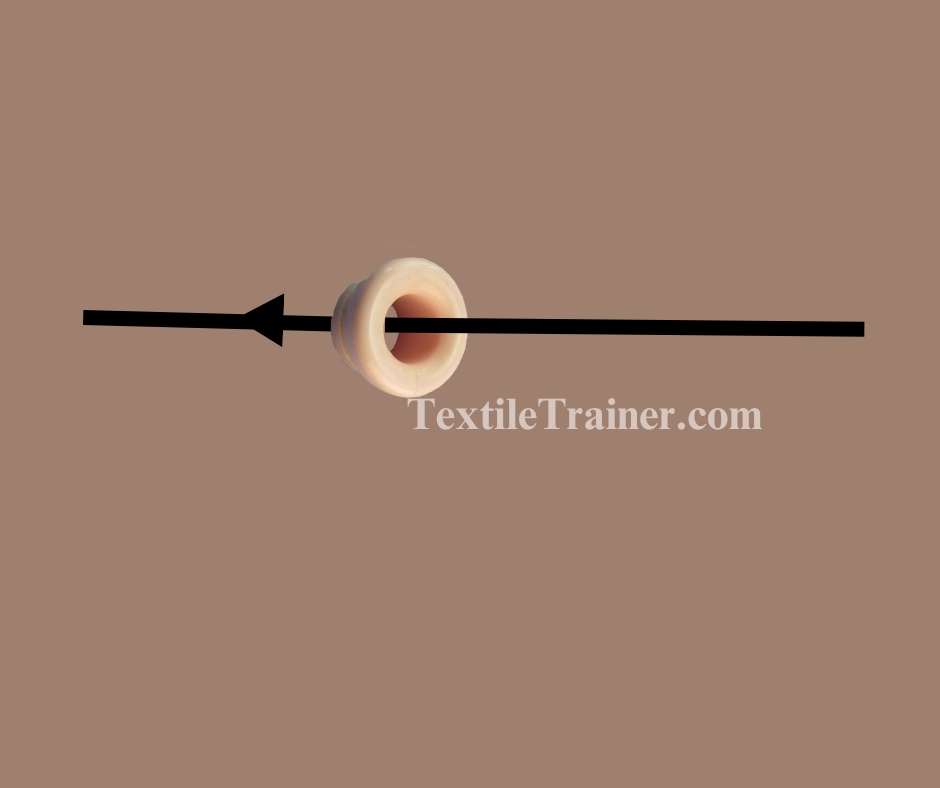

Ceramic Insert Type Yarn Guide:

Ceramic insert yarn guides are a specific type of yarn guide that is commonly used in high-speed textile manufacturing processes. They consist of a ceramic insert that is embedded into a metal or plastic holder. The ceramic insert provides a smooth, low-friction surface for the yarn to pass over, which reduces the risk of damage to the yarn and increases the speed and efficiency of the manufacturing process. Ceramic insert yarn guides are highly durable and resistant to wear and tear, which makes them a popular choice for textile manufacturers. The ceramic material is hard and durable, which allows it to withstand the high speeds and friction generated during the manufacturing process. The smooth surface of the ceramic insert also helps to reduce friction and eliminate the risk of snags or breaks in the yarn.

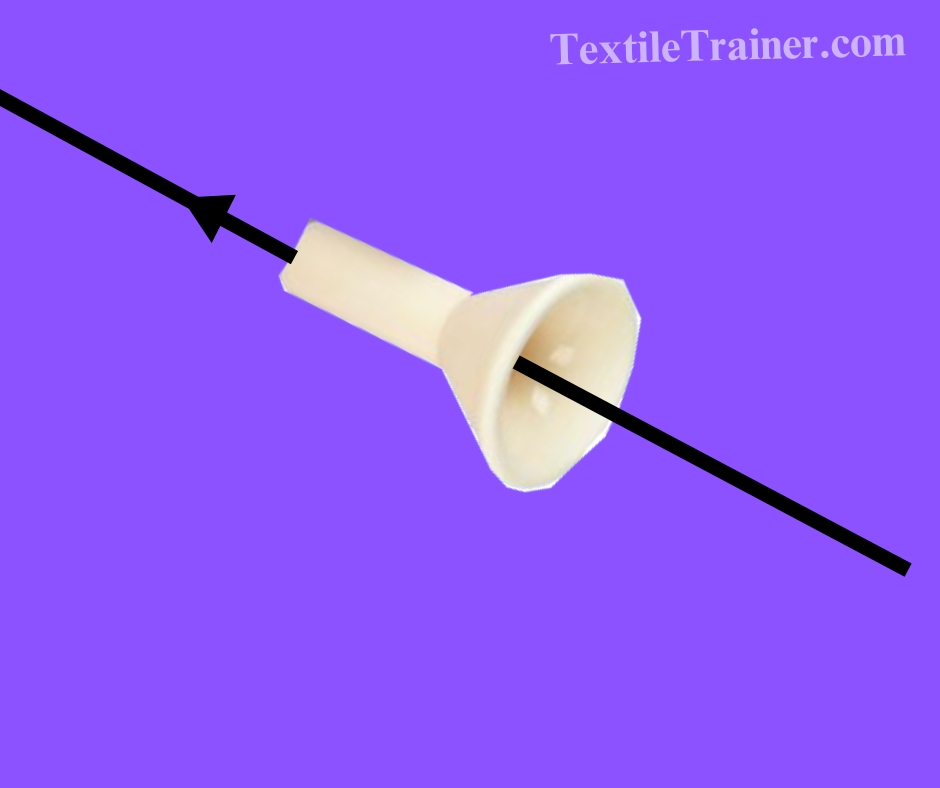

Trumpet type yarn guide:

A trumpet yarn guide is a specific type of yarn guide that is commonly used in textile manufacturing processes. It is called a “trumpet” guide because of its shape, which resembles a musical instrument. The trumpet yarn guide consists of a cylindrical body with a tapered, funnel-shaped opening at one end. The yarn is threaded through the narrow end of the guide, and the wider end is positioned facing the direction of the yarn’s travel. The trumpet guide’s shape helps reduce the tension on the yarn and prevent snags or breaks during the manufacturing process.

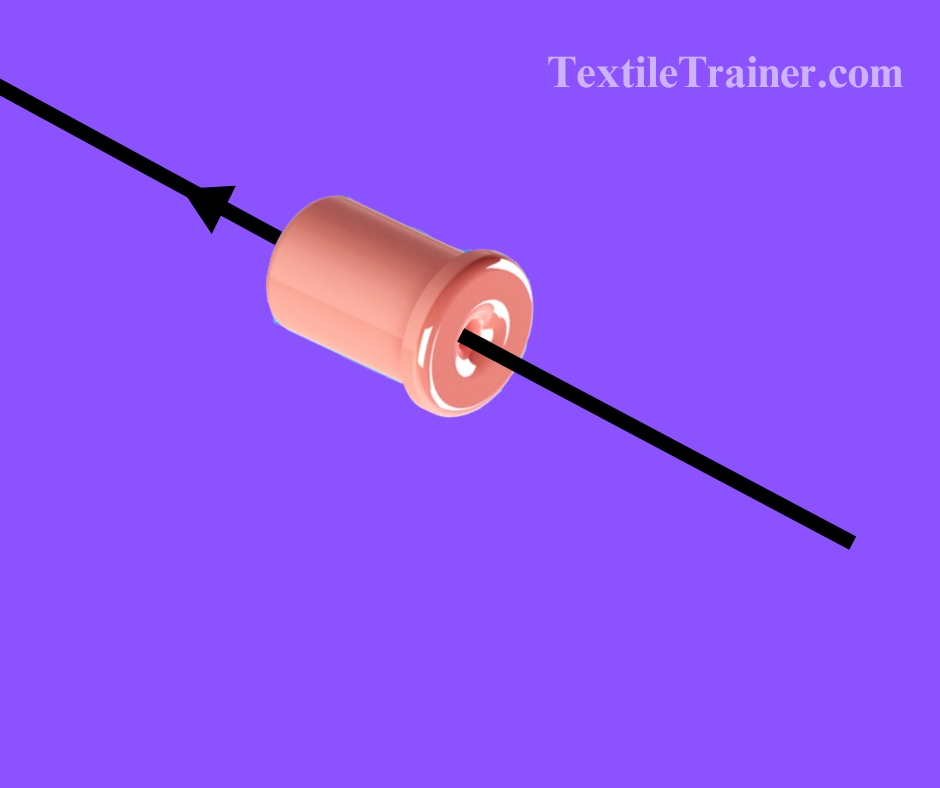

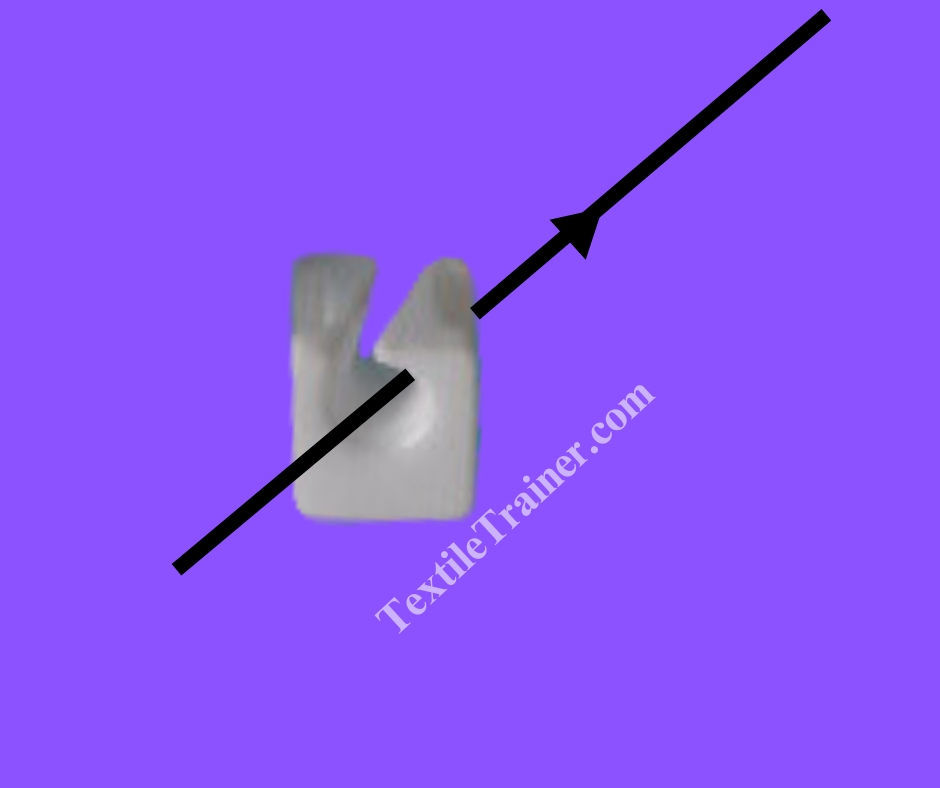

Bush type yarn guide:

Bush-type yarn guides are a specific type of yarn guide that is commonly used in textile manufacturing processes. They consist of a small, cylindrical bush that is mounted onto a holder or bracket. The yarn is threaded through the brush’s centre, which helps guide it through the manufacturing process. Bush-type yarn guides are typically made from a hard, durable material such as ceramic, tungsten carbide, or stainless steel. The choice of material depends on the specific needs of the manufacturing process, the type of yarn being used, and the conditions under which the equipment operates.

Advantage of Closed Yarn Guides

- Prevents snarling and twisting of the yarn: The closed design of the guide prevents the yarn from snarling and twisting, which can lead to breakages and other problems during the manufacturing process.

- Better tension control: The closed design allows for better control of the tension on the yarn, which helps to ensure consistent and high-quality output.

- Suitable for high-speed processes: Closed yarn guides are well-suited for high-speed processes, as they can guide the yarn through the manufacturing equipment quickly and efficiently.

Disadvantage of Closed Yarn Guides

- More susceptible to wear and tear: Closed yarn guides can be more susceptible to wear and tear over time, especially if they are used with abrasive or high-tension yarns. This can lead to a shorter lifespan and the need for more frequent replacements.

- More difficult to clean: The closed design of the guide can make it more difficult to clean, which can lead to contamination and other issues in the manufacturing process.

- Limited flexibility: Closed yarn guides are less flexible than other types of guides, which can make it more difficult to guide the yarn through complex or irregular paths in the manufacturing equipment.

2. Type-B: Opened Yarn Guides:

An open yarn guide is a type of yarn guide used in textile manufacturing equipment that helps to guide the yarn through the manufacturing process. Unlike a closed yarn guide, which encloses the yarn as it is fed through the guide, an open yarn guide has a gap or opening through which the yarn passes. Open yarn guides are commonly used in low-speed textile manufacturing processes, such as in producing cotton, wool, or other natural fibers. They are often made from materials that are resistant to wear and tear, such as ceramic or hardened steel, to withstand the friction generated during the manufacturing process.

Opened yarn guides may classified into three. they are:

- Pig Tail Opened Yarn Guide.

- Slotted Cuides Opened Yarn Guide.

- Post Opened Yarn Guide.

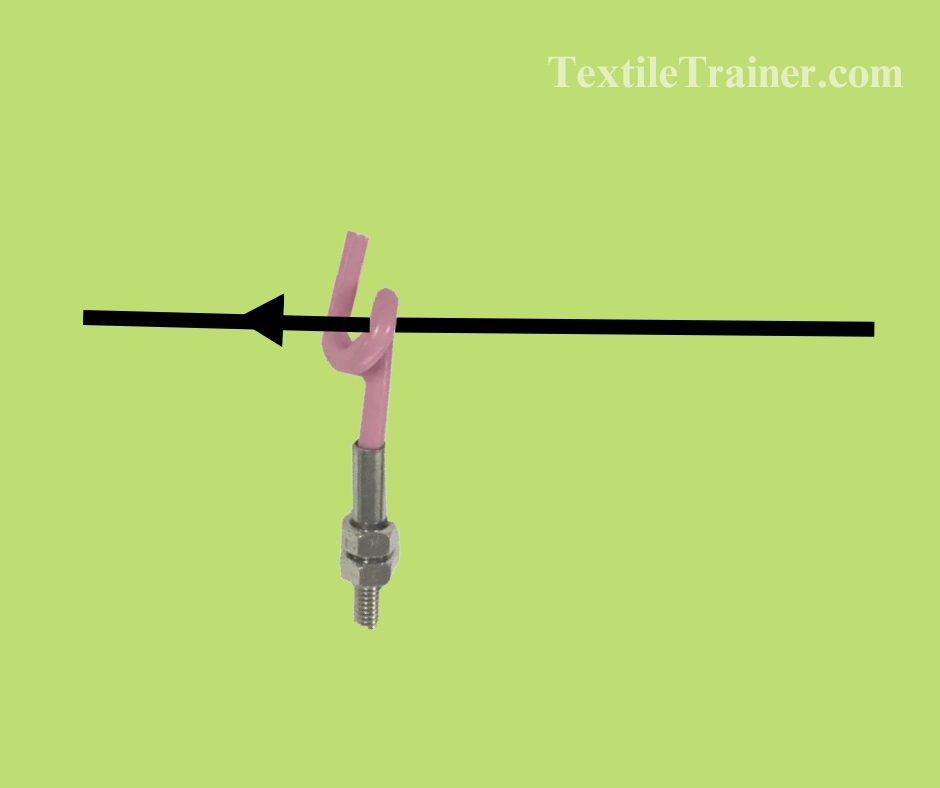

Pig Tail Opened Yarn Guide

A pigtail yarn guide is a specific type of yarn guide that is commonly used in textile manufacturing processes. It is called a pigtail guide because of its distinctive spiral shape, which resembles that of a pig’s tail. The pigtail yarn guide consists of a small, spiral-shaped metal wire that is mounted onto a holder or bracket. The yarn is threaded through the spiral’s centre, which helps guide it through the manufacturing process.

Slotted Cuides Type Yarn Guide

A slotted yarn guide is a specific type of yarn guide that is commonly used in textile manufacturing processes. It consists of a metal or plastic holder with a narrow slot or channel through which the yarn is threaded. The slotted yarn guide is designed to help guide the yarn through the manufacturing process while also providing a measure of control over the tension and direction of the yarn. The narrow slot or channel helps keep the yarn in place, reducing the risk of snags or breaks during manufacturing.

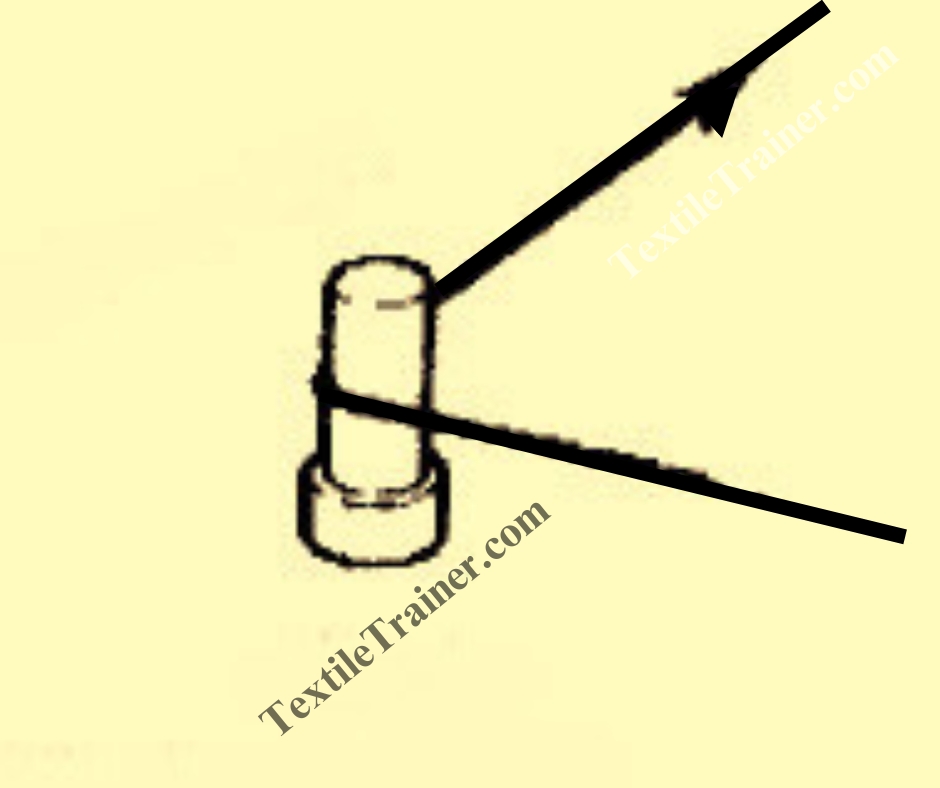

Post Type Yarn Guide

A post yarn guide is a specific type of guide commonly used in textile manufacturing processes. It comprises a metal or plastic post or rod mounted onto a holder or bracket. The yarn is threaded through a hole or eyelet in the post, which helps to guide it through the manufacturing process. The post yarn guide is designed to help guide the yarn through the manufacturing process while also providing a measure of control over the tension and direction of the yarn. The hook or loop at the top of the post helps keep the yarn in place, reducing the risk of snags or breaks during manufacturing.

Advantage of Closed Yarn Guides

- Easy to clean: The open design of the guide makes it easier to clean and maintain, which can help to prevent contamination and other issues in the manufacturing process.

- Flexible: Open yarn guides are more flexible than closed guides, which makes them well-suited for guiding yarn through complex or irregular paths in the manufacturing equipment.

- Longer lifespan: Open yarn guides can have a longer lifespan than closed guides, as they are less susceptible to wear and tear over time.

Disadvantage of Closed Yarn Guides

- Risk of snarling and twisting: The open design of the guide can increase the risk of the yarn snarling or twisting, which can lead to breakages and other problems during the manufacturing process.

- Limited tension control: The open design of the guide can make it more difficult to control the tension on the yarn, which can lead to inconsistent output.

- May not be suitable for high-speed processes: Open yarn guides may not be as well-suited for high-speed processes as closed guides, as they may not be able to guide the yarn through the manufacturing equipment as quickly and efficiently.

Finally we can say, yarn guides play a crucial role in the textile manufacturing process. They help guide yarn through the machinery, ensuring it is appropriately tensioned and controlled. There are various types of yarn guides, including closed guides, open guides, ceramic insert guides, trumpet guides, bush types guides, pigtail guides, and slotted guides. Each type of yarn guide has its advantages and disadvantages and is suitable for different applications and types of yarns. Textile manufacturers can make informed decisions on which guides to use to achieve the best quality and efficiency in their processes by understanding the different kinds of yarn guides and their applications. Overall, yarn guides are a small but essential component of the textile industry. Their proper selection and use can make a significant difference in the quality and consistency of the final product.

Spot on with this write-up, I actually believe this amazing site needs much more consideration. I’ll oftimes be once more to learn additional, thank you for that information.

thank you for stay with us….Please share my article in your social media.