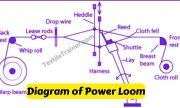

What is Loom?

The device which is used to produce woven fabric is called loom. The basic purpose of any loom is to hold warp threads under tension to facilitate the interweaving of the weft threads. In this article, we will describe different parts of handloom and their function with appropriate figure.

Major Parts of Loom:

The major components of a hand loom are listed below:

- Warp thread/Ends.

- Weft thread/picks.

- Heald shaft.

- Treddle or treadle.

- Sley or slay.

- Shuttle box.

- Shuttle.

- Picker.

- Reed.

- Warp beam or weaver’s beam

- Back rest or back beam

- Front rest or breast beam.

- Cloth beam

- Lease rods

- Temple

Now, I will discuss all the major parts of loom with Function.

1. Warp thread/Ends:

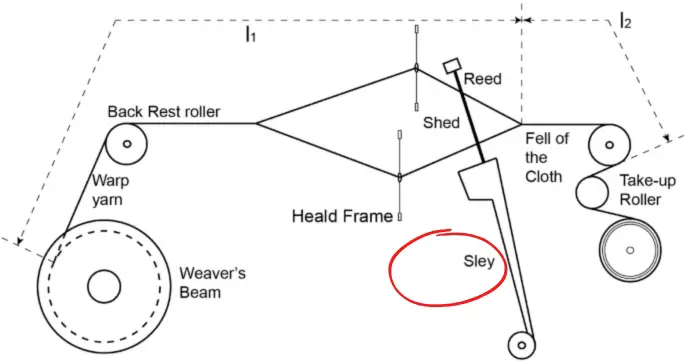

The longitudinal threads in a loom running from the weaver’s beam over the back rest through the eyes of the healds and dents of the reed, over the front rest to the cloth roller, are termed warp threads. The interlacement between the warp and the weft takes place to the fell of the cloth, and the piece between the fell of the cloth and the cloth roller is termed “cloth or fabric”

2. Weft thread/Picks:

The transverse threads running from one selvedge to the other selvedge of the fabric through the division of warp threads are termed “weft thread”. A single thread of warp is known as an “end” and a single thread of weft in known as a “pick”. The wefts or ends are divided into two layers for the insertion of a pick of weft through this division.

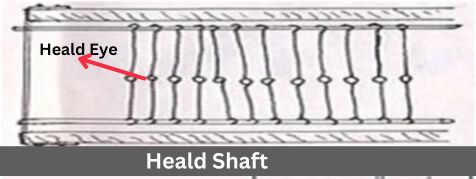

3. Heald shaft:

It is composed of two wooden or iron laths upon which a series of twine cords or wires are suspended. In the middle of each cord or wire there is an “eye” through which a warp thread passes.

Function of heald shaft:

- It keeps the warp threads in proper order or sequence.

- It forms shedding.

- The predetermined and successive order of elevating and depressing the required number of healds, in each pick of the repeat, goes to form the design or pattern in a fabric.

- It helps to detect the broken ends.

- The number of ends per inch or 2.54 cm. in cloth is determined by the counts of helad used.

4. Treddle or treadle:

The treadle is a pedal or lever placed under a loom with which a heald is connected by means of cords. In the reverse direction, the heald is connected in such a way that when the treadle is pressed sown, the heald may go down to form the lower layer of the shed.

5. Sley or slay:

The sley is a wooden frame accommodating two shuttle-boxes, a sley race, a reed, a reed cap and two sley-swords and swings forward and backward. At its forward motion the last pick of weft is beaten up to the fell of the cloth, and at its backward motion the shuttle is allowed to pass over the sley-race through the open shed.

6. Shuttle box:

The shuttle box is a rectangular wooden casing for the dwell of a shuttle and is situated at both ends of the sley race. It provides a spindle and a picker. As an alternative the shuttle-box may be grooved inside length way to accommodate a picker.

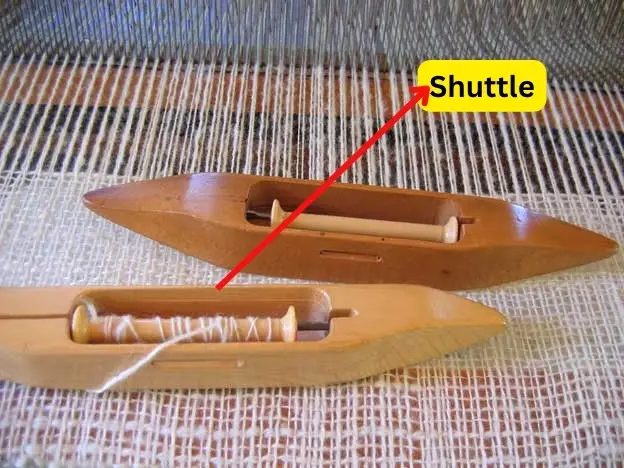

7. Shuttle:

The shuttle is a vehicle for weft and passes through the divided warp for the interlacement of the warp and weft. When stationary, the shuttle resides in the shuttle-box. The shuttle is used for picking.

8. Picker:

The picker is a piece of leather or other material placed in grooves or on a spindle inside a shuttle box and is used to give a blow to the shuttle to drive it from one box to another. It sustains the force of the shuttle while entering a box.

9. Reed:

The reed is a comb fixed on a sley with a reed cap. The open space between two combs or wires is termed a “dent”. One, two or more ends are passed through each dent of the reed. The number of dents on two inch of reed gives its counts.

Function of reed:

- It keeps the warp threads in their respective positions.

- It acts as a guide of the shuttle to pass from one shuttle box to another.

- It beats up the last pick of weft to fell of the cloth.

- The density of the combs of the reed, in conjunction with the set of the heals, determines the fineness of the cloth.

10. Warp beam or weaver’s beam:

The roller, upon which the warp yarn is wound and fitted to the bottom at the back of the loom, is termed “warp beam” or weaver’s beam. In handlooms the weaver’s beams generally contains up to one hundred meters of warp yarn or so, whereas in power looms it may contain up to several thousand meters.

11. Back rest or back beam:

It is a fixed bar or roller placed above the weaver’s beam and acts as a guide for the warp threads from the warp beam to pass alternately over and under the lease rods through the eyes of the healds and dents of the reed, then over the front rest to the cloth beam.

12. Front rest or breast beam:

It is a fixed bar or roller placed in front of the loom above the cloth beam and acts as a guide for the cloth to wind it on to the cloth beam. The cack rest and the ront rest keep the warp yarn and cloth horizontal and under proper tension to facilitate weaving.

13. Cloth beam:

The roller, upon which the cloth is wound when weaving, is fitted in front of the loom below the breast beam and is termed cloth beam. In most handlooms the cloth is manually wound on the cloth roller at regular intervals during weaving or sometimes by means of a train of wheels pick by pick.

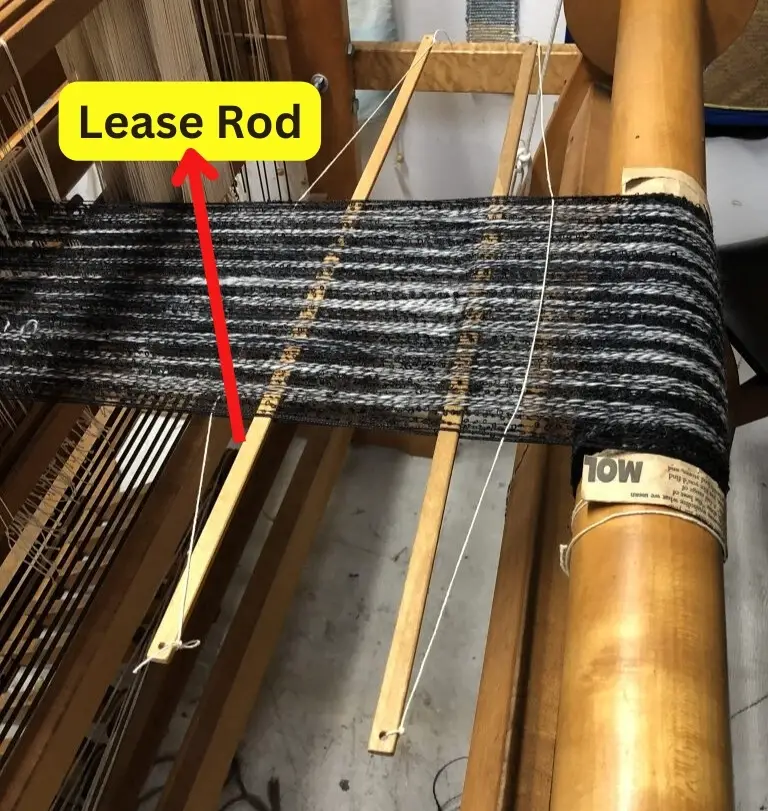

14. Lease rods:

The division of warp threads into one or one, two and two and so on is termed “lease”. The two rods passed between the two successive divisions of warp threads are called lease rods. Lease rods are placed between the back heals and the back rest, but nearer to latter.

Function of lease rods:

- It places the warp threads in serial numbers.

- It helps to detect the broken ends.

- It forms the last end of the divided warp.

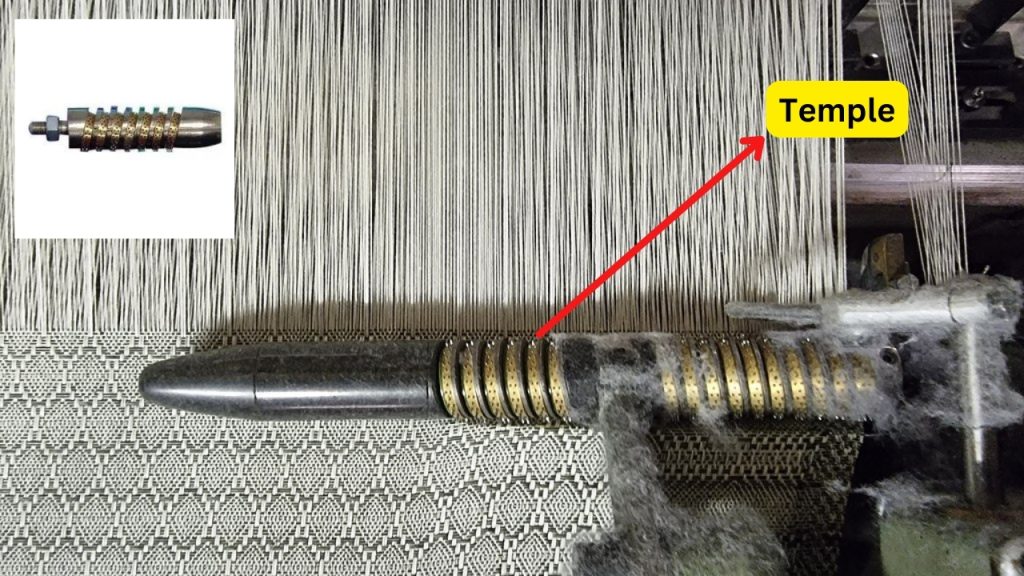

15. Temple:

The temple as used in handlooms is an implement consisting of two pieces of wooden bars or bamboo sticks, with pins hinged at two opposite ends. The two pieces are tied together by strings in such a way that they can be extended or contracted to stretch the cloth at its fell.

You May Read:

I simply enjoy the useful details you provide in your writings.