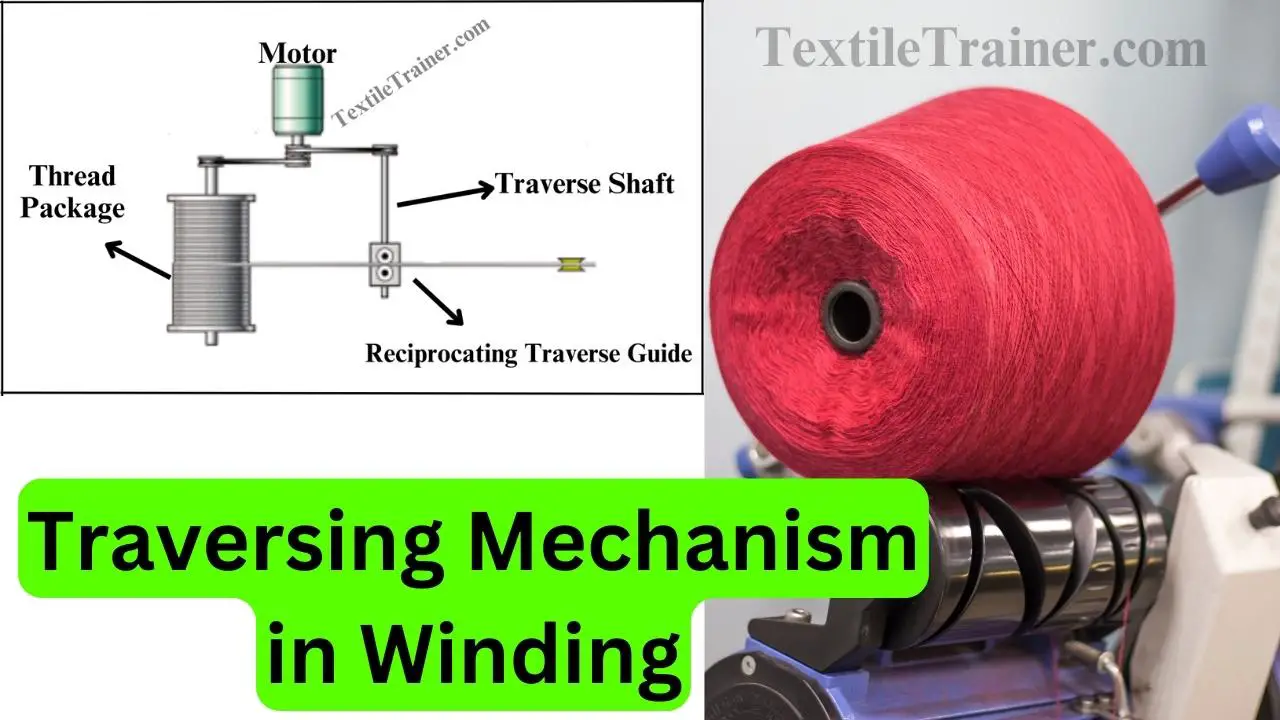

What is Traversing Mechanism?

The term traversing mechanism refers to a system for evenly distributing yarn across a winding package or bobbin’s width. Yarn winding involves winding yarn onto a package or bobbin to make storage, transport, or processing convenient. Yarn should be evenly distributed across the package’s width during the winding process. A variation in tension, density, or appearance of the wound yarn can adversely affect the quality and performance of the yarn in subsequent processes. When yarn is wound, traversing mechanisms typically involve the yarn moving laterally across the package or bobbin.

Kinds of Traversing Mechanism:

Traversing mechanisms refers to a range of systems that facilitate movement between positions. These mechanisms play a crucial role in engineering, robotics, manufacturing, and transportation. As a result, objects, tools, and equipment can be traversed in a controlled and precise manner, which ensures efficient operations and accurate positioning.

Different types of traversing mechanisms are used to perform various tasks in different applications. The following are some of the most common types of traversing mechanisms:

- Reciprocating traverse mechanism.

- Disc or groove drum traverse mechanism.

- Linear traverse mechanism.

- Electronic traverse mechanism.

- Oscillating traverse mechanism.

- Stepping traverse mechanism.

- Programmable traverse mechanism.

The major types of traverse mechanisms used in the textile industry are reciprocating traverse mechanisms and disc or groove drum traverse mechanisms. This article aims to discuss these two types of traverse mechanisms in more detail.

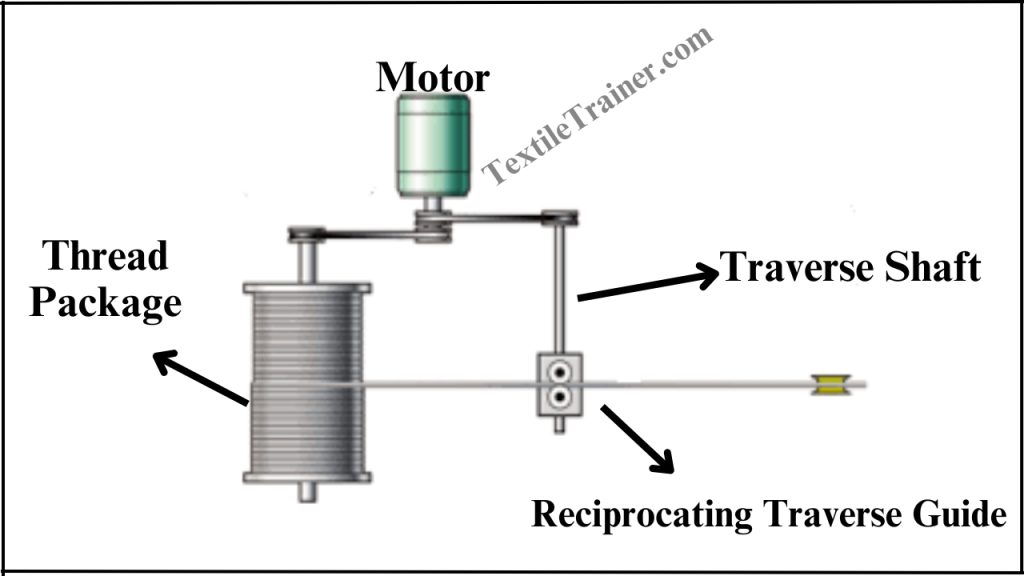

Reciprocating traverse mechanism

Reciprocating traverse mechanisms are used to distribute yarn evenly across the width of a winding package or bobbin. It ensures that the wound yarn is uniform in density, tension, and appearance. When yarn is wound, a reciprocating traverse mechanism uses a linear path to move the yarn guide back and forth. Using this mechanism, the yarn will not be wound in a concentrated area, resulting in uneven winding and potential issues during subsequent steps. It guides the yarn along the length of the package or bobbin during winding by guiding it laterally across the width. In a reciprocating motion, it distributes the yarn evenly across the entire width of the package.

Various mechanisms can be used to reciprocate the yarn guide. A reciprocating mechanism driven by a motor is one common approach. Motors drive crankshafts or cam mechanisms, which convert rotational motion into linear reciprocating motion. Afterwards, this motion is transferred to the yarn guide, which moves back and forth. The reciprocating traverse mechanism adjusts yarn guide speed and stroke length. As a result of this adjustability, the winding pattern can be customized to meet specific requirements, such as package width, yarn type, and traverse pattern requirements. The reciprocating traverse mechanism is used in yarn winding to ensure an even distribution of yarn across the package or bobbin. Thus, ensuring high-quality output and facilitating subsequent processes like knitting, weaving, and dyeing are made possible by maintaining consistent tension, density, and appearance of the wound yarn.

In summary, reciprocating traverse mechanisms contribute to optimum yarn winding by ensuring uniform yarn distribution, minimizing variations in tension or density, and enhancing overall wound package quality.

Disc or Groove Drum Traverse Mechanism

A groove drum traversing mechanism is commonly used in yarn winding processes. In the winding process, it facilitates lateral movement or traversing of yarn around a winding package or bobbin. Distributing the yarn evenly ensures that the wound yarn maintains constant tension, density, and quality.

A groove drum traversing mechanism consists of a drum or cylinder with a grooved surface. When the drum rotates, the grooves guide the yarn back and forth across the width of the package as it is wound around the drum. The grooves and the tension of the yarn interact to cause lateral movement of the yarn. Depending on the winding requirements, the grooves on the drum can be of different shapes and configurations. The most common groove designs are V-grooves, helical, or spiral grooves. A grooved design is selected based on yarn type, package size, traverse pattern, and winding speed.

In yarn winding applications, the groove drum traversing mechanism offers several advantages. In addition to ensuring uniform distribution across the package width, it provides a simple and effective means of traversing the yarn. The grooves on the drum guide the yarn precisely, minimizing the possibility of overlapping or gaps. As well as being relatively simple to implement and maintain, groove drum mechanisms are often used in yarn winders. It is compatible with various winding systems, including manual, semi-automatic, and fully automated ones.

Ultimately, the groove drum traversing mechanism is critical to achieving high-quality yarn winding. It helps maintain consistent tension, density, and appearance of the wound yarn in subsequent processes such as knitting, weaving, or dyeing by facilitating controlled lateral movement across the package width.

Differences Between Reciprocating Traverse Mechanism and Groove Drum Traverse Mechanism:

In order to understand the differences between reciprocating traverse mechanisms and groove drum traverse mechanisms in yarn winding, we must first understand their significance. Traversing mechanisms are essential for achieving uniform yarn distribution and maintaining consistent tension, density, and quality. They ensure that the yarn is evenly wound by guiding it across the package width, minimizing the possibility of overlaps or gaps. Let’s explore the differences between reciprocating traverse mechanisms and groove drum traverse mechanisms in yarn winding.

| S/N | Reciprocating traverse mechanism | Groove drum traverse mechanism |

| 1 | Reciprocating traverse mechanism consists of a yarn guide or traverse guide that moves back and forth in a linear path across the width of the winding package. | Groove drum traverse mechanism involves a drum or cylinder with a grooved or threaded surface. |

| 2 | The motion pattern is a reciprocating back and forth motion. | The motion pattern is typically continuous rotation. |

| 3 | The yarn guide moves in a straight line across the width of the package. | The yarn follows a zigzag or helical path across the package due to the grooves or threads on the drum’s surface. |

| 4 | The stroke length, speed and frequency of the reciprocating motion can be adjusted to control the yarn’s traverse width and pattern. | The traversing path can be adjusted by changing the design of the drum such as altering the groove shape, pitch or depth. |

| 5 | Reciprocating traversing mechanisms are versatile and commonly used in a range of yarn winding applications due to their ability to create traverse patterns. | Drum traversing mechanisms are well-suited for applications where continuous rotation and spiral winding are desired. |

In summary, the traversing drum mechanism depends on a rotating drum with grooves or threads to guide the yarn in a continuous spiral or zigzag pattern. In contrast, the reciprocating traversing mechanism utilizes a linear motion of a yarn guide across the package width. As the reciprocating mechanism provides precise control over the traverse pattern and can be adapted to various winding requirements, the drum mechanism offers continuous rotation and adjustable traverse paths.